R&D departments can play a critical role in helping manufacturers achieve their net-zero environmental goals. Companies across industries are reducing their CO2 emissions by optimizing their supply chains and creating new business models, among other initiatives. But there are additional aspects of environmental sustainability—natural-resource depletion, ecosystem changes, and pollution—that also need to be addressed. To tackle all the challenges, manufacturers must reevaluate how they design both new and existing products. In fact, a product’s design influences as much as 80% of its environmental impact, according to the European Commission.

In our experience, companies can reduce a product’s environmental impact by up to 40% by utilizing conventional design technologies. But to fully eliminate that impact, they will need to use next-generation deep tech, such as architected materials, synthetic biology, and universal printing. The strong business case for investments in these technologies includes reducing costs (by limiting exposure to CO2 taxes and energy cost fluctuations, for example), gaining competitive advantages, and promoting regulatory compliance.

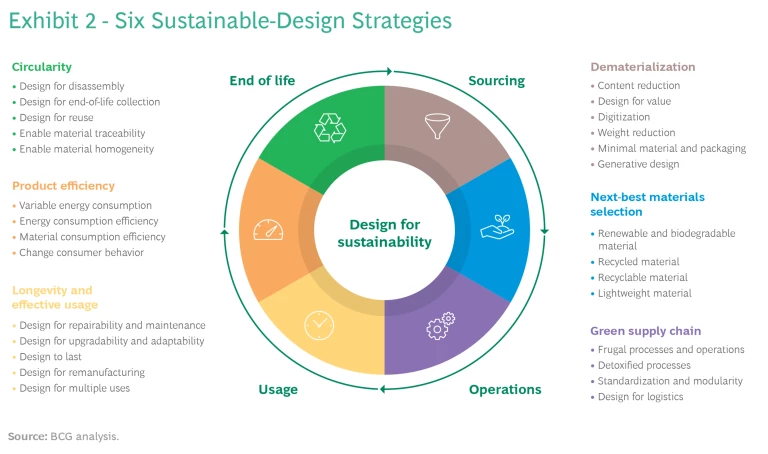

R&D departments can use six complementary strategies to guide their sustainable-design efforts. But they cannot apply these strategies on their own. They must collaborate with an innovation ecosystem that includes suppliers, operations and sustainability experts, and academics. Such partnerships are crucial to making the right tradeoffs involving cost, environmental impact, and customer perception.

Start by Measuring the Environmental Impact

A product’s design strongly influences its ecological sustainability because numerous engineering-related aspects affect the environment, including the product’s composition, lifespan, efficiency, and recyclability. Measuring the impact provides insights that companies can use to apply design strategies that promote sustainability.

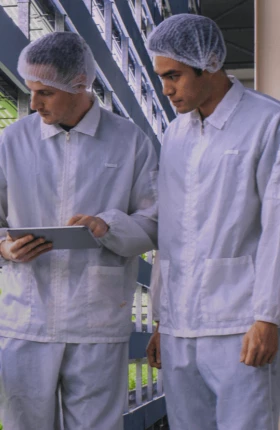

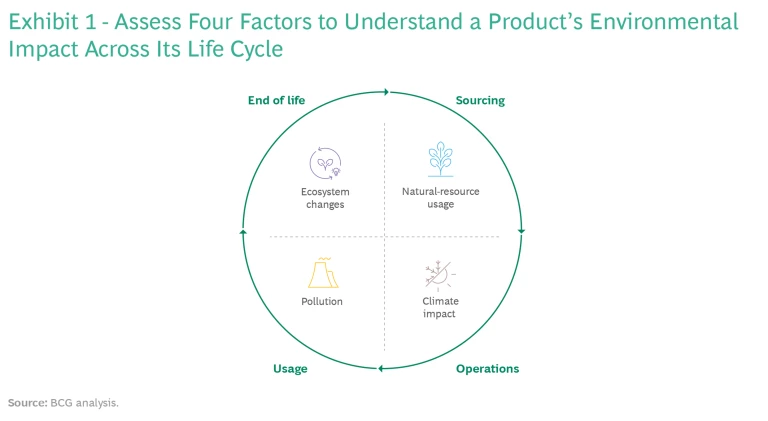

To determine where to focus their efforts, companies need to identify a product’s environmental impact across its life cycle—from sourcing and manufacturing to usage and end of life. The assessment should consider the planetary boundaries—such as limits to ozone depletion and ocean acidification—that will maintain a stable environment and decrease the risk of irreversible change. As shown in Exhibit 1, companies should assess four factors to gain this kind of comprehensive view:

- Climate Impact. Measure CO2 emissions along the value chain.

- Natural-Resource Usage. Identify the resources used, such as materials depleted during sourcing and water used during production.

- Ecosystem Changes. Assess how the product life cycle affects land, freshwater, and oceans, such as through deforestation or eutrophication.

- Pollution. Determine the levels of chemicals and dangerous gases released into the atmosphere during each phase of the product’s life cycle.

For each factor, companies must choose KPIs that align with their overall sustainability goals and areas of focus. These KPIs can be used to track progress over time and set targets.

Six Design Strategies

We have grouped sustainable-design principles into six complementary strategies that address all of these factors across the product life cycle. (See Exhibit 2.) Each strategy offers opportunities but also presents challenges.

1. Dematerialization

Companies can find ways to use less material in products or packaging while still providing the required functionality. Significant benefits are possible across the entire life cycle, generally in proportion to the level of material reduction.

In addition to using less material, companies can take advantage of digitization—that is, substituting software for analog features. With digitization, features can be added without increasing a product’s weight or the amount of material used. Software also provides more flexibility for future adaptations. Applying a “less is more” principle to material usage creates opportunities to develop new business models that promote sustainability while reducing costs and meeting customer needs.

In defining a dematerialization strategy, companies should consider the need to influence the preferences and mindset of consumers. For example, the preference of many drivers for spacious and fully equipped vehicles will need to change before smaller cars with fewer features gain acceptance. Moreover, manufacturers must find ways to ensure the same level of safety and security in vehicles with leaner construction and fewer high-tech features.

2. Next-Best Material Selection

Companies can often select materials that minimize a product’s environmental impact without significantly diminishing its functionality. Options include biodegradable, recycled, recyclable, or lightweight materials. For example, researchers at Clemson University have developed a plant-based substitute for the polyurethane foam commonly used in car seats and mattresses. This durable, bio-based material is recyclable and avoids the health risks associated with polyurethane.

Weight reduction is an important consideration in selecting materials. Lower weight can reduce energy use over a product’s lifetime. One startup automaker has found that using lightweight composite materials reduces a vehicle’s energy consumption by 50%.

Switching to alternative materials is not easy, however. Next-best materials are often more expensive than traditional ones. Moreover, selecting materials entails a complex set of considerations and criteria, including physical properties, compatibility, safety, and supply.

A greener supply chain can reduce costs by reducing energy consumption and facilitating the use of more resilient processes and digitization.

3. Green Supply Chain

To promote a greener supply chain, companies can select materials, parts, and components that reduce the environmental impact of logistics and production. They can also design production processes to shorten supply chains. A greener supply chain can reduce costs by reducing energy consumption and facilitating the use of more resilient processes and digitization. Capturing these benefits requires transparent and effective collaboration among R&D, production, supply chain teams, and suppliers.

4. Longevity and Effective Usage

Companies can improve and extend a product’s useful life by designing it to facilitate repairs, upgrades, and adaptations. Products can also be designed to allow for multiple uses or remanufacture for other uses.

Although extending product lifetimes can delay consumers’ adoption of new products and reduce revenues, companies can still capture many benefits. For example, product longevity can increase customer loyalty and enhance a brand’s reputation. Companies can also charge a premium for products with longer lifespans, which consumers often regard as being of higher quality. Finally, companies can generate additional revenue through repair and maintenance services.

5. Product Efficiency

An efficient product is one that consumes the minimum possible amount of energy and material resources. Improving efficiency is the best way to reduce the carbon footprint during use, which is typically when the highest level of emissions occurs. Consumers, too, want more efficient products, in order to counteract high energy prices.

In designing more efficient products, companies must consider the tradeoffs with other benefits. For example, large, comfortable vehicles, such as SUVs loaded with features, are comparatively inefficient to operate.

Eventually, once the circular value chain is mature and optimized, secondary materials will cost less than primary materials.

6. Circularity

Circularity is essential to reducing the consumption of materials and energy. It can be promoted by sourcing recyclable materials as well as by designing a product for “second life” uses. For example, because remanufacturing requires much less energy than extracting the primary materials from which a product was made, it significantly reduces energy consumption and carbon emissions. Eventually, once the circular value chain is mature and optimized, secondary materials will cost less than primary materials.

Designing for circularity is challenging, however. The life cycle of an engineered product involves numerous suppliers with which companies must collaborate to develop an efficient circular design. There are also financial hurdles. For example, even when a mature process for recycling a component exists, it may not be economical if demand for the material is low or the cost of recycling exceeds the resale value.

Vehicle seats are a case in point. Recycling intact seats is not profitable because their resale value is much lower than the cost of removal. As a result, the metal that makes up 75% of vehicle seats is typically recycled, while the remaining materials are incinerated.

Establish Enablers

To support their efforts, companies need to establish six enablers:

- KPIs and Targets. Define KPIs against which the impact of a design on sustainability will be measured, and set the associated targets, taking into consideration the broader corporate strategy. Set the metrics and targets at the departmental level and cascade them down throughout the R&D organization. Use scorecards to report results at all organizational levels.

- Processes. Incorporate design for sustainability principles into R&D processes, from early-stage ideation through quality gates.

- Tools. Embed environmental impact data in existing design support tools (such as computer-aided design). Use life cycle assessment databases and IT capabilities (such as digital twins and generative design) to compare solutions.

- Governance. Select owners to lead pilots and manage projects. Decide who is responsible for achieving targets and what levers they have available to steer the organization.

- Capabilities. Develop employees’ sustainable-design capabilities and recruit new personnel to close skill gaps. Provide the financial resources required to reach targets.

- Partner Network. Develop external partnerships or joint ventures with academic institutions and startups. Promote internal collaboration through open innovation labs and incubators.

Stay ahead with BCG insights on climate change and sustainability

Apply a Systematic Approach

A systematic approach to reducing the environmental impact of products has four main steps.

Create a baseline. Develop a detailed quantitative and qualitative baseline of environmental impact that encompasses the climate impact, natural-resource usage, ecosystem changes, and pollution associated with the product across its life cycle. In addition, examine how your competitors are designing products for sustainability and assess how those efforts could affect your competitive position in the market. This includes examining technological trends (such as by identifying valuable new patents) and comparing designs through teardowns of competitors’ products.

Generate ideas. Apply the six strategies to generate ideas for sustainable designs. Create a multidisciplinary team to lead the effort, including operation experts, design experts, suppliers, venture capital investors, climate and sustainability experts, and academics. It is more effective to generate ideas for optimizing designs at the product level than at the component level.

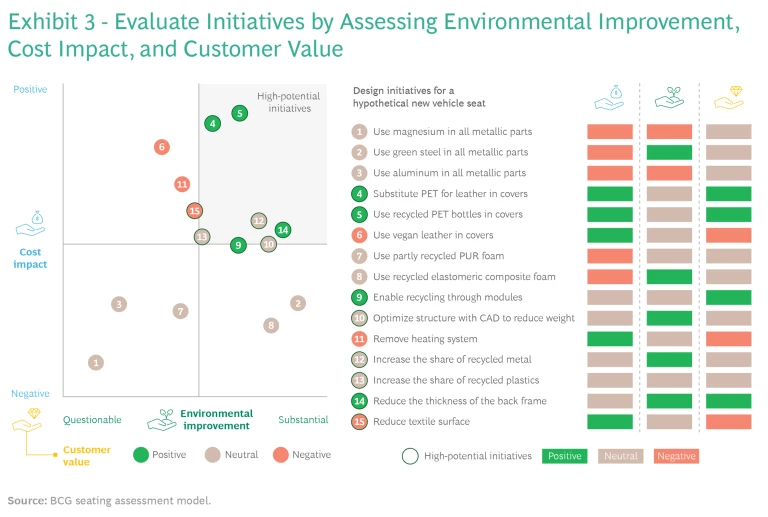

Evaluate and prioritize ideas. Evaluate and prioritize ideas with respect to three criteria: environmental improvement, cost impact, and customer value. (See Exhibit 3.) The most promising initiatives promote substantial environmental improvements and reduce costs, while also being appreciated by consumers. However, companies will often need to make tradeoffs among these criteria.

Test the feasibility of ideas. Evaluate the practicality and potential for success of each idea. Use an agile and iterative approach so that developers can gather customer feedback during the development phase. If possible, conduct a pilot to gather real-world data and feedback before fully committing to an idea.

Beyond the benefits to society, there is a strong business case for designing products to reduce their environmental impact. Companies can achieve short-term cost savings and long-term competitive advantages by meeting consumer demand for sustainable products and preparing to comply with new laws and regulations. Indeed, for many companies, long-term viability is at stake. The challenges arising from resource depletion and climate change have made sustainable practices, including design principles, essential to maintaining a business over the long run. Companies that take steps today to capture the full range of sustainable-design benefits will position themselves to thrive in the decades ahead.