In today’s increasingly volatile business landscape, organizations that excel at integrating technology into their operations achieve unparalleled competitive advantages. Leading companies such as DHL, Zara, and Amazon have strategically leveraged technology to drive efficiency, agility, and innovation across procurement, manufacturing, supply chain, and customer service.

Yet despite these clear advantages, many companies fall short of achieving their technology goals. Indeed, BCG’s research finds that 65% of digital transformations fail to achieve their stated objectives. In many cases, the root cause is an overly simplistic binary choice: to either buy off-the-shelf solutions or build entirely custom tools. Organizations frequently underestimate integration complexities, data infrastructure requirements, and the ongoing demands of customization and scalability. These challenges underscore the need for a more nuanced, hybrid approach.

A hybrid "buy and build" strategy enables companies to rapidly benefit from proven commercial solutions while selectively developing proprietary capabilities tailored to their specific operational needs. This approach promotes faster time to value through proven solutions, greater differentiation via proprietary add-ons, and ongoing adaptability to evolving business conditions.

Mastering a hybrid strategy requires disciplined evaluation of build or buy options and a flexible technological infrastructure. Critically, companies must also invest in strong, adaptive internal capabilities to integrate and extend vendor solutions and stay ahead of their development roadmaps. Organizations that build this kind of flexibility into their tech infrastructure and talent model will be better positioned to lead—or at least to fast follow—in the rapidly changing landscape of operational innovation.

Stay ahead with BCG insights on operations

Why the Binary Approach Falls Short

A purely buy or build approach is too rigid for the complexities and rapid pace of today's operational environment. Alone, each falls short for a number of reasons.

Buying doesn’t live up to its promised ease. Off-the-shelf products are often presented as the fastest route to value, whether for transactional functions, such as warehouse management, or more advanced capabilities, such as planning. However, speed often comes at the expense of flexibility, integration ease, and long-term relevance. Integration with legacy systems is rarely "plug and play" to the degree vendors promise. Genuinely unlocking the value of even commercially available solutions requires significant hands-on effort, such as fine-tuning parameters, enriching datasets, or upgrading algorithms.

Building offers flexibility but demands clear decisions about scope and investment pacing. Custom solutions require upfront commitments in capital and talent, often before returns are proven. Yet this approach avoids vendor lock-in and enables modular, business-aligned growth. Success depends on funding only what drives measurable value, scaling at a sustainable pace, and making focused tradeoffs as priorities evolve. The “pay as you grow” model works best when leaders actively manage risk, ROI, and technical complexity along the way.

Integration complexity compounds the challenges. Many companies underestimate the difficulty of integrating new technologies, whether bought or built, into their existing tech infrastructure, as well as the limitations imposed by rigid implementation approaches. Traditional technology stacks, exemplified by rigid ERP ecosystems, often lack the flexibility and scalability necessary to adapt to rapid business changes. Moreover, organizations frequently rely on outdated waterfall methodologies for technology deployments, rather than using the more iterative, agile approach required for modern systems.

The rise of AI-powered "agentic" systems highlights the limitations. AI agents enable organizations to move beyond automating isolated systems toward optimizing entire end-to-end value chains. The new environment requires internal agentic middleware—custom-built deep agents sitting in a transversal tech layer, capable of leveraging datasets from different sources and using multiple systems to power cohesive, automated workflows. Neither buying nor building alone can fully deliver this level of orchestration.

The Hybrid Approach Begins with a Technology Blueprint

Rather than first purchasing technology and then customizing it, organizations increasingly evaluate multiple technology components simultaneously in order to move from isolated, siloed optimizations toward integrated, end-to-end performance improvements. This approach requires clearly defining how different layers of the technology stack will interact and then deliberately designing them to fit seamlessly together from the start. In this purposeful layering, it is critical to determine early on where genuine differentiation resides and how to develop and control the related capabilities.

One effective framework for developing a technology blueprint is vertical hybridization, where each layer of the stack gets its own tailored approach. For example:

- The system’s backbone (for instance, ERP) is often best served by stable, off-the-shelf solutions that provide reliability and foundational functionality.

- The data layer is typically built internally using established cloud platforms and tool chains, reflecting the importance of owning data quality, structure, and availability.

- The AI and decision logic layer usually combines purchased algorithms with in-house fine-tuning and customization to establish differentiation through proprietary insights and unique capabilities.

- The agents layer—where orchestration and execution agents interact with each other and across systems—is typically custom-built by leveraging commercial frameworks and resources, such as cloud services or agentic platforms.

- The user interface and workflow layer are often customized to closely match the workflows, preferences, and real-world requirements of operational teams.

A well-designed blueprint identifies the short- and long-term costs and benefits of each alternative. By strategically targeting internal builds, organizations can achieve faster impact than is possible through lengthy system deployment projects. These early wins can help fund ongoing initiatives, engage and motivate the organization, establish robust data practices upfront, and proactively rewire operational processes. Ultimately, this structured approach increases both the likelihood of achieving intended outcomes and the speed at which organizations capture sustainable value.

Key Factors in Structuring a Buy-and-Build Decision

Determining precisely which technology components to buy and which to build requires a structured decision-making framework. Companies should systematically evaluate five key factors.

Strategic Value. Identify where technology directly supports competitive differentiation. High-value areas that deliver distinct advantages to customers or operations typically warrant customized development and internal ownership, whereas commoditized functions can often be addressed effectively by standard solutions.

Maturity of Solutions. Evaluate whether robust, proven vendor solutions exist for the desired capability. Mature off-the-shelf products usually offer reliability and rapid deployment, making them preferable when differentiation is minimal or unnecessary. Conversely, if available offerings have capability gaps or limitations, custom solutions might be needed.

Customization and Integration Needs. Consider how extensively standard solutions would need tailoring to align with your organization’s unique operational processes and existing tech stack. If heavy customization is unavoidable, a targeted in-house build might provide more control, flexibility, and lower long-term costs than an extensive modification of off-the-shelf products.

Cost Versus ROI. Weigh short- and long-term costs against the expected return on investment. Buying is typically faster upfront, but licensing fees and maintenance can add up over time. Building often demands a higher initial investment, but it can reduce ongoing expenses and create a lasting competitive advantage.

Pace of Change. Assess how quickly your company must innovate and adapt its technology and processes to keep pace with market dynamics. Organizations that require rapid responsiveness and continuous evolution might find that building internally provides essential flexibility and agility. In contrast, those able to accommodate longer vendor release cycles or slower adaptation may find buying external solutions a better option.

The Benefits of the Hybrid Approach: Two Case Studies

By rigorously applying this structured assessment, organizations can clearly and deliberately decide when it makes sense to buy, when it is best to build, and how to strike the optimal balance. The following two examples illustrate how organizations navigate the buy-and-build continuum—from leveraging purchased solutions enhanced with targeted, custom-built features to achieving transformative, step-change improvements through substantial internal development.

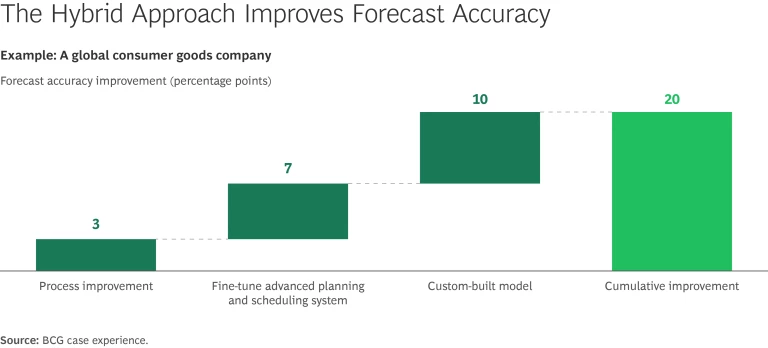

Customized Enhancements. A global consumer goods company sought to transform its supply chain planning capabilities by implementing an advanced planning system (APS). With a complex product portfolio and fluctuating regional demand, the company required a solution that would seamlessly integrate with its existing ERP and logistics infrastructure while providing specialized insights into procurement and inventory optimization.

The company took a hybrid approach. Initially, it selected a leading APS vendor, allowing it to benefit from prebuilt optimization algorithms and industry-standard forecasting models. Then, recognizing that the standard APS offering fell short in areas requiring deeper customization, it developed proprietary, AI-driven enhancements. These custom add-ons delivered hyperlocal demand forecasting, constraint-based production scheduling, and tailored replenishment strategies that aligned closely with the company’s unique operational requirements.

By starting with foundational process improvements, then fine-tuning the off-the-shelf APS system, and finally layering on custom-built models, the company achieved a cumulative 20-percentage-point improvement in forecast accuracy. (See the exhibit.) Each stage contributed meaningful gains, highlighting how buying and building in tandem can unlock value that neither approach could deliver alone.

In addition, this hybrid model allowed the company to reduce planning cycle times by 40% and decrease stockouts by 25%. These improvements accelerated value creation, enabling the company to achieve the objectives of its supply chain planning transformation program.

Step-Change Improvements. A global logistics services provider is reshaping how it delivers value to customers by embracing a build-and-buy approach to GenAI. The company used GenAI to gain a competitive advantage in the complex process of responding to customer requirements for supply chain solutions. Specifically, it leveraged GenAI across three interconnected, strategic functions:

- Solution Design. A proprietary GenAI tool automates the process of cleaning, sorting, and analyzing data from prospective customers. Integrated with existing software, the tool gives engineers faster access to high-quality inputs, reducing time to market and enabling more effective, tailored logistics designs.

- Sales. Using a proprietary GenAI tool that rapidly analyzes customer requirements, sales teams can develop customized proposals faster and with greater precision. By removing the manual burden of upfront analysis, the tool frees up sales reps to focus on client-specific challenges.

- Legal and Customer Support. An off-the-shelf GenAI tool assists in summarizing customer inquiries, processing legal documents, and resolving routine service issues—speeding up cycle times while maintaining quality.

By integrating GenAI solutions with custom-built data pipelines and intuitive user interfaces, the company created a unified, customer-centric ecosystem. The result: deeper insights, faster responses, and a measurable uplift in personalization and operational effectiveness. More than a technology upgrade, this hybrid approach has become a strategic enabler—positioning the company to deliver smarter, faster, and more differentiated services at scale.

Establishing the Foundations of Success

Successfully implementing a hybrid buy-and-build approach requires rethinking technical strategy as well as organizational capabilities. By combining robust infrastructure investment, internal capability development, agentic AI, and continuous improvement, organizations can unlock greater adaptability and value.

Invest decisively in a future-proof tech backbone. A modern, cloud-native data platform that delivers clean, trusted data at the speed demanded by the business is essential to enabling the effective integration of external and internal technologies. Companies that upgrade this layer typically compress integration timelines by 30% to 50% and unlock two to three times faster payback on digital investments. Three design choices are crucial:

- A domain-oriented, integration-ready architecture that uses APIs to enable today’s systems and is designed to support AI agents tomorrow—allowing teams to plug in new vendor modules or custom-built services within days, not months

- A real-time, event-driven data fabric that keeps every application working from the same source of truth—vital for AI-driven decision engines

- A composable security and governance, built directly into the platform, that allows innovation to scale without compromising resilience or compliance

Develop strong internal capabilities. Even when organizations rely heavily on external solutions, investing in internal expertise remains vital. Organizations need skilled in-house technology talent—including product managers, data scientists, and engineers—to quickly adopt and adapt cutting-edge technologies, such as GenAI, autonomous agents, and dynamic data platforms. These experts can also help companies make informed decisions when selecting and negotiating with technology vendors.

To integrate tech and operational capabilities, leading organizations are establishing “ops tech centers.” These cross-functional hubs combine expertise from operations, standards, and technology functions into a single, integrated team.

Operational experts collaborate closely with technology specialists, who provide complementary capabilities. Ops tech centers ensure that technology initiatives align closely with real-world operational requirements, enable rapid testing and scaling of custom enhancements, and foster a culture of continuous innovation. Additionally, these centers attract and cultivate digital talent, helping to embed agility into the organization's technological DNA.

Leverage agentic AI digital factories. The emergence of AI‑powered agentic systems is poised to further tip the scales toward the hybrid model by dramatically reducing the cost and effort of building proprietary capabilities. Rather than assembling large teams of external developers or outsourcing entire software projects, companies will be able to rely on lean internal squads that harness autonomous AI agents for code generation, refinement, and deployment.

These agentic digital factories shift performance metrics away from traditional “man‑days” toward value‑based benchmarks focused on output efficiency and strategic impact. As a result, organizations can prototype, customize, and scale internal solutions far faster and at lower cost, making granular builds feasible in areas that were previously out of reach.

Ensure continuous improvement. A hybrid buy-and-build strategy should be viewed not as a one-time technology deployment but as a dynamic and iterative journey. Companies must balance achieving quick wins from purchased solutions with building flexible, internally developed capabilities that can evolve over time. A culture of continuous improvement ensures regular recalibration of tools and processes, driving sustained efficiency and innovation.

A hybrid buy-and-build approach elevates technology implementation from a tactical choice into a powerful strategic advantage. By thoughtfully balancing external solutions with internally developed capabilities—and integrating them into a cohesive technology ecosystem—organizations can achieve both immediate benefits and long-term differentiation. Companies that master the challenges of blending external technology with proprietary innovations will position themselves as industry leaders in operational performance.