Education

- PhD, electrical engineering and business administration, RWTH Aachen University and Massachusetts Institute of Technology

- MS, electrical engineering and business administration, RWTH Aachen University and Massachusetts Institute of Technology

- MS, École Centrale Paris

Daniel Küpper leads Boston Consulting Group's Operations practice in Germany and Austria, as well as leading the Innovation Center for Operations in Central Europe. He is also a core member of BCG’s Center for Digital in Industrials.

Since joining the firm in 2004, Daniel has focused on operations, primarily lean and manufacturing. He has led numerous projects defining manufacturing strategy—including the achievement of deeper value and better make-or-buy decisions—and optimizing manufacturing networks.

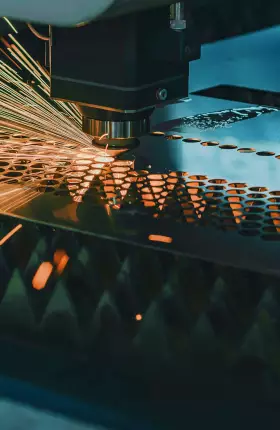

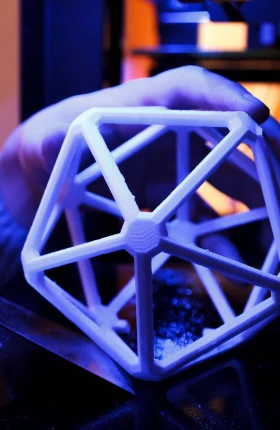

Daniel has worked extensively on the issue of how manufacturing plants can operate at maximum value and foster continuous improvement. This includes implementing lean production systems and driving cost improvement projects. He also has specific expertise sharpening processes in direct and indirect manufacturing and in making the best use of assets—including technology assessments, industry 4.0, and advanced robotics.

Before joining BCG, Daniel worked in research facilities at MIT and RWTH Aachen University.