Large-scale disruptions force companies to pivot or perish. The pandemic has caused industrial manufacturers around the world to adapt as they faced unique and acute challenges and hustled to keep operations live. At Tata Steel BSL (TSBSL), a group company of Tata Steel, the company’s large workforce of 25,000—including employees and contractors—had to be on site each day during the pandemic to maintain business continuity, and hundreds of truck drivers had to enter and leave its facilities daily. As coronavirus cases rapidly multiplied in India, TSBSL’s leadership rolled out a comprehensive plan to ensure employee safety while the business operated. The pandemic isn’t over, but the company has shown immense resilience, garnering the trust of employees, customers, and the communities in which it operates.

In fact, the crisis precipitated a kind of forced experiment in reimagining the company’s ways of working under extremely tough circumstances. Through this experience, TSBSL developed its own template to power out of a crisis. The company has become far more digitally enabled, agile, and innovative, and it is now applying the crucial lessons it learned from the pandemic response to build a foundation for the future.

An Unprecedented Crisis

In the early days of the coronavirus outbreak, TSBSL’s senior leaders, led by their managing director, navigated multiple rapid-fire challenges. The leaders met on alternate days to bring alignment and agility on critical matters, such as estimating weekly production plans for customers in hard-hit industries, securing raw materials, redefining the company’s go-to-market approach, and ensuring business resilience. Above all, the company wanted to keep its large workforce safe. Across India, manufacturers faced large-scale outbreaks that led to sporadic factory shutdowns and adverse impacts on an already-precarious financial outlook for their businesses.

TSBSL, with operations spread across several locations in India, required a large, 24-7, multishift workforce, and employees had to work in close proximity with one another. In addition, the diversity of its workforce and work environments meant that the early off-the-shelf solutions developed for urban, office-based, and less rugged environments would not suffice. Although checklists and protocols were available from local authorities and industry groups, TSBSL leadership determined it needed a more robust solution that was designed to meet its specific requirements and unique needs.

TSBSL’s First Response

To ensure business continuity, TSBSL set up a cross-functional Impact Center, which BCG defines as a physical or virtual space where leaders meet to plan and execute change initiatives. Leaders are supported with a set of routines to manage the change and processes to track and visualize progress. Chaired by the COO, the Impact Center’s staff included line managers, medical practitioners, safety professionals, HR executives, and technology leaders. The group met virtually every day to design solutions, discuss challenges, and refine the plan. Within two weeks, the team developed a comprehensive framework called Kavach (it means armor in Sanskrit) to mitigate the risk to employees and ensure continuing operations safely. (See “Six Layers of Risk Mitigation.”)

Six Layers of Risk Mitigation

Government Guidelines. The company required that all employees follow the government’s guidelines, which included wearing a mask, maintaining the appropriate social distance, and regularly washing hands. These were simple rules, but the company focused on strategically communicating them repeatedly and consistently.

Workforce Pods. TSBSL segmented its entire workforce into pods, with a maximum of ten employees per pod, to help employees avoid physical contact with other employees who were outside their pod. Each pod was self-sufficient in executing its responsibilities, and pods could not work across shifts or directly interact with other pods other than by phone. Some specialized functions, such as maintenance, were authorized to visit pods and required to follow additional safeguards. For example, maintenance employees had to wear face shields, record visits in a simple digital app to enable contact tracing—which middle managers could do in real time—and sanitize equipment and surfaces after their visits. Over time, the pod concept became a clear differentiator when TSBSL’s practices were compared with those of other companies. Pods restricted the spread of the coronavirus to only the immediate pod members, and real-time tracking ensured that if an employee tested positive, primary contacts could be detected within one hour.

Employee Movement. For each type of employee (such as security guards, supervisors, locomotive drivers, and salespeople), TSBSL mapped out movements into and out of the workplace. For instance, hundreds of truck drivers from different states visited and spent significant time inside the plant each day. After carefully analyzing their movements inside the plant, the company arranged separate resting areas with the provision for food, set up separate washrooms, and made transactions paperless. Hundreds of such small changes were made in TSBSL’s ways of working.

Shift Breaks. At each shift changeover, outgoing workers sanitized their equipment or workstation and left 15 minutes in advance, and then incoming workers entered 15 minutes late and sanitized again. For critical operations that required continuous staffing, such as the blast furnace control room, the company provided additional personal protective equipment to ensure a safe hand over.

Medical Support. The company created a 24-7 help line that workers could call if they started having coronavirus symptoms. In parallel, the company rapidly ramped up its in-house medical infrastructure by installing 400 new patient beds and hiring 40 medical and support employees to help TSBSL staff as well as their families.

External Stakeholders. External agents, such as contractors and visitors, were educated and enabled to adopt the company’s protocols for continued business with TSBSL.

TSBSL had recently undertaken a turnaround of its business, and management knew that the change required to implement the Kavach framework would be enormous. Yet the organization was committed to conducting a pilot, making mistakes, learning, and repeating swiftly. TSBSL rapidly rolled out the safety protocols, explained the new norms through an extensive outreach, embraced the challenge of assigning each employee to a pod (a group of about ten coworkers), conducted mock drills for better preparedness, and devised innovative ways to monitor adherence and course correct along the way.

As a result, TSBSL has experienced fewer disruptions owing to the pandemic, compared with other manufacturers. Moreover, the successful implementation of the Kavach protocols has strengthened its pact with its employees and supply chain partners.

Building for the Future

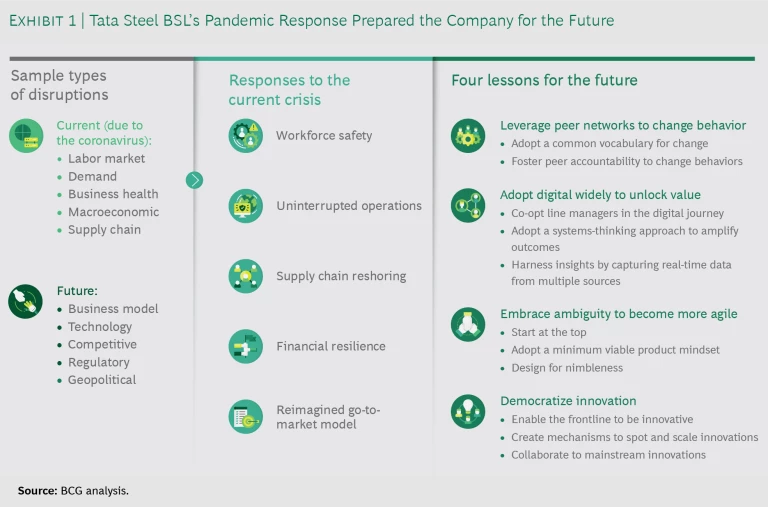

As businesses emerge from this pandemic, they must expect ambiguity in the external environment to remain high because of new technologies, competitive forces, evolving policies and regulations, and unpredictable geopolitical events, among other factors. TSBSL’s leaders are working to meet the dual challenge. The company is remaining relentlessly focused on the health and safety of the employees while it leverages the insights gleaned from its implementation of the Kavach framework to power out of the crisis and build for the future. (See Exhibit 1.)

The goal for companies is not to return to the prepandemic status quo but to build the right foundational platforms and capabilities that will allow them to navigate continued volatility. By applying these lessons to improve its operations and compete effectively in a far more dynamic environment, TSBSL is bouncing back quickly. Business leaders can use these lessons as a template for their own context and response to current—or future—disruptions.

Leverage Peer Networks to Change Behavior

Changing employees’ behaviors is incredibly hard, especially in large workforces. Many organizations try to alter behaviors through top-down edicts, leading to changes that don’t last (if they happen at all). Through the Kavach framework, TSBSL ensured that behavioral changes took root by using the employee pod structure to adopt a common vocabulary and foster peer accountability.

Adopt a common vocabulary for change. In the initial days of the outbreak, as checklists and protocols from multiple sources streamed in, it was important to establish a single version of the truth. The six-layer Kavach framework acted as a tremendous cohesive force, as it provided clarity and built confidence among a large, diverse workforce that the organization was truly focused on ensuring employees’ safety. Moreover, in the design and implementation of the protocols, middle management worked extensively with shop floor workers to understand their employee movements, high-risk touch points, and adoption challenges. New behavioral norms were communicated and reinforced using mailings, messages in social media channels, posters, and other communication vehicles. As workers adopted the various norms, they felt part of the process. In one operating unit, they enacted a street play to promote social distancing and explain the concept of pods. The video went viral, and it resonated with other workers who saw their colleagues advocating the new norms.

Foster peer accountability to change behaviors. Each pod served as a peer network that was responsible for collective work output, which required behavioral changes among all pod members. Each pod nominated a leader to be the group’s conscience, ensuring individual responsibility and collective accountability for adopting the safety protocols. During some pilot stages, TSBSL observed significant breaches of protocol. However, once stabilized, these pods ensured that changes in behavior stuck. For example, pod members collectively confirmed that each member sanitized his or her tools and workspaces at the start and end of each shift. As workers realized the effectiveness of pods and the peer accountability approach, their confidence grew, as did their resolve to rigorously comply with other protocols as well.

The renewed sense of camaraderie that was facilitated by pods is now changing behaviors in other ways.

The renewed sense of affiliation and camaraderie that was facilitated by pods is now changing behaviors in other ways. For instance, pod members nudge each other to follow better workplace cleanliness and housekeeping practices. Better housekeeping is already leading to reducing the number of safety incidents on the shop floor. Similarly, on complex topics such as environmental sustainability, TSBSL’s peer network mantra of “responsible me, responsible we” is encouraging employees to do their part to improve air quality and reduce water consumption.

Adopt Digital Widely to Unlock Value

The development and implementation of the Kavach framework was accelerated by the extensive use of digital solutions, not only as a powerful enabler to facilitate health and safety protocols but also to track adherence across massive facilities. (One of TSBSL’s sites, the integrated steel plant, is spread over 1,600 acres, or roughly 900 football fields.)

Co-opt line managers in the digital journey. When the company was designing the online system to capture pod visits (that is, workers’ visits to other pods), the line managers who would ultimately use the system provided insights, such as the potential areas for mistakes when filling out a form and whether the questions were easy to understand. Armed with these inputs, TSBSL simplified the front-end design of the system. The system now proactively provides line managers with a weekly pod-visit history for each employee in their unit, thus simplifying contact tracing and reducing avoidable visits. Incorporating early inputs from line managers ensured buy-in, fast-tracked adoption, and helped reduce business friction.

Adopt a systems-thinking approach to amplify outcomes. TSBSL used systems thinking to link various digital solutions and applications and to generate better results. For example, the company initially deployed infrared, camera-based thermal scanners at entry points to screen workers for coronavirus symptoms. It then augmented this standalone solution with a facial-recognition-based registration tool, and it linked these to employee databases (including pod rosters) and government lists of high-risk areas, creating a multiplier effect. TSBSL is now rolling out more than 20 applications on the same integrated system to restrict workers who have left containment zones from entering a plant, as well as to capture working hours and analyze attendance patterns.

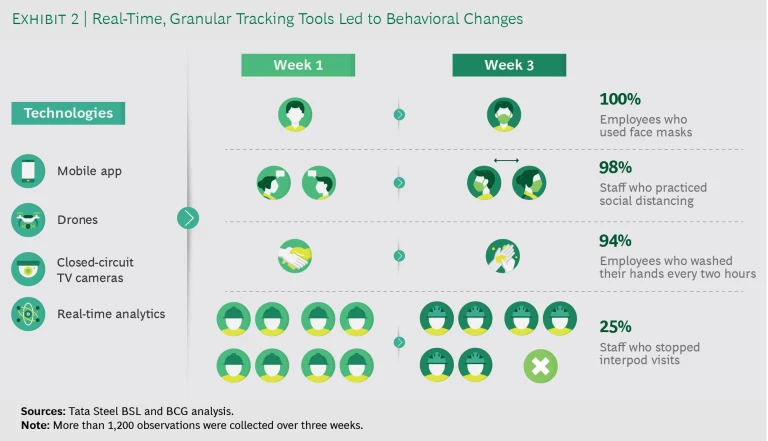

Harness insights by capturing real-time data from multiple sources. As Kavach initiatives were rolled out, the leadership team had no tools to track compliance and measure effectiveness. TSBSL set up a real-time, mobile, data-capture system to track employee adherence to various protocols. (See Exhibit 2.) The company complemented that employee-provided information with data from closed-circuit cameras (including feeds from overhead drones). Analytics on the data generated actionable insights for the leadership team and led to effective interventions, such as increasing adherence to face shield rules for contractors or sending tool sanitization reminders at the start of shifts.

The experience has been so enriching that management has rebooted its digital transformation journey, and some early results are already visible. TSBSL is now rolling out a tracking system based on wearable devices. The system not only improves workforce safety but also restricts unauthorized access to hazardous areas, improves compliance with regulations (such as overtime payment by contractors), and enhances productivity. Similarly, by applying a systems-thinking approach, the GPS devices that are installed on trucks are now being linked to when trucks are inbound (to ensure loading cranes and manpower are available when trucks arrive) and outbound (to provide real-time supply chain visibility to customers) to provide a multiplier digital effect.

Embrace Ambiguity to Become More Agile

Faced with the progression of the coronavirus, evolving local and federal regulations, and unpredictable supply chain disruptions, TSBSL’s leadership embraced ambiguity to become more agile.

Start at the top. TSBSL’s daily Impact Center meetings paved the way for agile decision making; leaders reviewed the team’s progress, incorporated cross-functional inputs, and made swift decisions that enabled a more successful implementation. For instance, early in the crisis, sourcing personal protective equipment was challenging owing to the company’s remote location and the nationwide lockdown. Instead of using the company’s robust yet time-consuming vendor enrollment process, the procurement team turned to a local nongovernmental organization (NGO) (a women’s support group) to supply face masks. When the quality was deemed acceptable, the team supported the NGO in ramping up operations, developing a reliable supplier while supporting the local community. The leadership team played a key role by adopting an untested process while ensuring that the risks were contained via a staged approach and that the stakeholders felt comfortable making such a decision. This set the stage for multiple similar decisions that became the order of the day during the pandemic.

Adopt a minimum viable product mindset. Given that TSBSL had no prior experience in dealing with such a disruption and no set of best practices to rely on, the company adopted a minimum viable product (MVP) approach, typically seen more in the context of agile startups. For instance, in the first three weeks of implementation, the company doubled the number of buses ferrying workers to TSBSL plants, eliminating the usage of public transport. Simultaneously, it placed purchase orders for closed-circuit TV cameras and thermal guns. In weeks three through five, workers were trained to occupy only alternate seats, and personal hand sanitizers were provided. In weeks five through eight, thermal screening was conducted at boarding points, cameras were installed on buses, and live feeds were analyzed centrally to monitor social distancing and face mask compliance. By adopting an MVP approach, TSBSL reduced the risk of contagion in multiple stages faster than it could have done otherwise.

Design for nimbleness. When TSBSL segmented its workforce into pods, the supply of labor was reduced and uncertain. The company had been running three eight-hour shifts, but it would need to shift to two twelve-hour shifts if the available labor fell below a certain threshold. The company designed pods and operating protocols for both schedules—a highly laborious process given the size of the workforce—enabling the company to switch schedules three times during a three-month period. TSBSL traded design redundancy for flexibility in operations and ensured that it didn’t lose sales owing to product unavailability at the point of sale.

TSBSL traded design redundancy for flexibility in operations and ensured that it didn’t lose sales.

TSBSL has started building agile principles of MVP and nimbleness into its maintenance practices. For example, when a piece of equipment recently broke down, the company opted to not lose time by waiting for the service provider to arrive. Instead, the team broke down the task into agile sprints. In sprint one, they used internal engineering knowledge and expertise to rectify part of the problem, and in sprint two, they remotely connected with OEM experts to resolve some of the more complex issues. By the time external help arrived on site, most of the issues were resolved, and it took only another three days to get the equipment online.

Democratize Innovation

The Kavach framework required that TSBSL adopt several innovations during the implementation. Many of those innovations came from frontline employees and managers.

Enable the frontline to be innovative. If agility needs to start at the top, innovation must spring from the frontline. One of the toughest challenges was to ensure social distancing and hygiene in common areas such as canteens, washrooms, and water coolers. The best solutions emerged by enlisting the help of those on the shop floor. Workers came up with an ingenious hands-free tap at hand-washing stations. (They turn it on by waving their metal-tipped safety shoes near it, which triggers a solenoid.) This led to a spate of microinnovations, including foot-operated water coolers, levers to convert regular doors into touch-free doors, and touch-free sanitizer dispensers—all of which significantly improved the company’s ways of working.

Create mechanisms to spot and scale innovations. Drivers entering the plant after traveling from different parts of the country posed considerable transmission risk. Yet the company couldn’t simply halt deliveries. To address the issue, the facilities team utilized scrap steel from the plant and built temporary rest shelters so that drivers could remain at a safe distance from the workforce. The leadership team further refined the shelters by installing benches and equipping some with portable washrooms. Over the next two months, management scaled up the idea by setting up more than 200 such shelters to be used by drivers and other short-duration visitors.

Collaborate to mainstream innovations. TSBSL leveraged ecosystem partners to take the early version of certain innovations and make them robust so that they could be rapidly scaled up. For instance, the company needed a sanitation unit that would spray disinfectants on the trucks before they entered the plant. TSBSL worked with a local vendor to design the unit, which was triggered by a sensor as a truck approached. However, during field trials, the spray was rendered ineffective by wind and a time lag in detecting incoming vehicles. TSBSL’s engineers collaborated with the vendor to adapt the nozzle and sensor design to address the problems. The improved design was later used by other manufacturers nearby.

The spirit of innovation also extended to normal operations as well. For instance, faced with constrained capital, TSBSL had to defer the purchase of its warehouse management software. Employees took this as a challenge and devised their own handheld-based solution, which helped them record and trace the physical location of steel slabs, or semifinished products, in inventory. TSBSL also had to curtail travel, which limited the information that salespeople were used to gleaning—and turning into sales—during on-site visits. But again, employees innovated. They replicated their in-person process as a virtual one, regaining the ability to gauge micromarket sales opportunities remotely.

The Kavach framework at TSBSL was ultimately extended to Tata Steel, the parent organization, which has more than 87,000 employees. Although the Kavach framework was originally created to mitigate the risks of the pandemic, the insights from its implementation are being used to build the foundation for the future.

Similar opportunities exist across other organizations. When a crisis hits, top-performing companies do more than merely hunker down and muddle through. Instead, the winners take bold, innovative steps to protect their people, learn from the experience, and use those insights to prepare for the future and generate a sustainable competitive advantage. The insights from TSBSL’s Kavach implementation provide a good starting point for other organizations to rethink their approach for a competitive and resilient organization of the future.

Tata Steel BSL Limited, a group company of Tata Steel Limited, is India’s fifth-largest flat steel producing company, with an existing steel production capacity of 5.6 million tons per annum. Tata Steel BSL has India’s largest cold-rolled steel plant and is one of the largest suppliers of automotive grade and high carbon special steel in the country. It recorded gross revenue of more than $2.4 billion in fiscal 2020 and has an employee base (including contractors) of more than 25,000.