In cooperation with the World Economic Forum and its Engineering and Construction Industry Action Group, BCG has developed a framework for a safe and efficient return to work in the construction sector. This article showcases a series of selected recommendations—illustrated by global best-practice examples arising from discussions with more than 15 global industry leaders—to help companies better navigate the current crisis and emerge stronger in the aftermath.

The engineering and construction (E&C) industry has a critical role to play in restoring some of the value that has been lost in a tough year. For that purpose, it is now crucial to keep working to guarantee a safe and efficient environment as lockdowns start to lift around the globe and activity resumes after a period of inactivity or slowdown.

A Framework for Restarting Work Safely and Efficiently in Construction

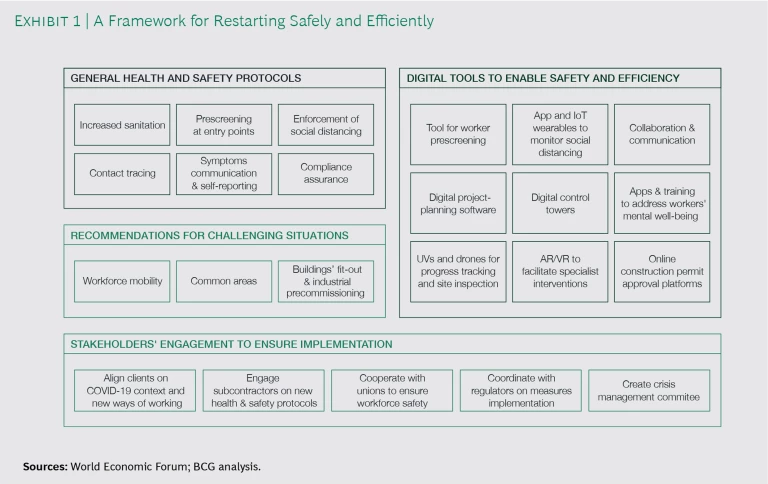

The E&C industry has found innovative and successful solutions for returning to work and responding to inherent particularities regarding human interaction, space limitations, and the physical nature of construction. Current conditions represent a unique opportunity to accelerate—and unlock the full benefits of— digital transformation within the industry. We’ve identified select recommendations and best practices in four categories that will help E&C companies return to work safely and efficiently (see Exhibit 1):

- Health and safety protocols and guidelines for construction activity

- Measures to overcome specific industry challenges

- Digital technologies that enable a safe and efficient working environment

- Coordination among key stakeholders to ensure an effective implementation of proposed actions

Health and Safety Protocols and Guidelines Specific to Construction Activity

By observing the practices implemented by leading E&C companies to comply with, and enhance, new working regulations released since the beginning of the COVID-19 pandemic, we have identified six sets of actions that have proven effective across projects and geographies (see Exhibit 2):

- Increased Sanitation. Enhance cleaning procedures daily across the site and at points of worker contact (such as tools, machinery, and vehicles), common areas (sanitation facilities, changing rooms, showers, and toilets), and worker transportation. Also, stress the use of mandatory personal protective equipment (PPE) in all work site areas and under all conditions.

- Prescreening at Entry Points. Implement rigorous testing for all onsite workers and visitors, regardless of their employment position or contact potential. To guarantee safety, ensure that entry points monitor the use of PPE, that they screen for influenza-like symptoms each time someone enters the site, and that a clear response protocol is in place for potential cases of infection.

- Enforced Social Distancing. Stagger work crews and break times, limit the number of people permitted to attend onsite project inductions, and substitute nonessential physical contact with automated processes.

- Contact Tracing. Identify clinically vulnerable workers to provide them with the needed safety measures. Establish prevention mechanisms and dedicated teams to monitor workers’ contacts both onsite and offsite. Extend jurisdictions for contact tracing beyond the work site in order to increase effectiveness.

- Improved Communication and Symptom Self-Reporting. Define a risk assessment framework and identify the proper responses for positive cases, signs of infection, and potential contact. Set up straightforward self-reporting processes for employee use.

- Compliance Assurance. Deploy a health and safety team charged with monitoring compliance, raising awareness, and reinforcing communication across sites.

The COVID-19 lockdown period has also raised employers’ concerns about workers’ mental well-being, since the effects of quarantine and lockdown generally appear from three to six months after isolation. Our research suggests that following lockdowns, workers suffer a significant increase in high, toxic levels of stress and an accompanying decrease in productivity, with respondents reporting that they feel about 35% less productive than usual. To support mental health and avoid stress-related absenteeism, companies should create mental well-being plans, raise awareness around the issue, observe at-risk employees, monitor compliance, and finally, ensure that working conditions are sustainable.

Solving for Challenging Working Conditions

Beyond the application of general health and safety protocols, E&C companies must further grapple with the industry’s inherent challenges of limited space and generally close physical human interaction. On the basis of these two factors, BCG has developed a framework for identifying risks in particularly challenging situations. As a result, construction companies should address specific recommendations to manage three common situations:

- Workforce Mobility. Construction workers face major health and safety challenges when traveling in buses or cars to and from construction sites, given the proximity and contact exposure of workers. Several initiatives should be put in place: engineered seat isolation systems, vehicle-capacity restrictions, daily sanitation, and staggered workforce transport times.

- Common Areas. Canteens and camps typically pose greater problems than construction sites, since the level of interactions is higher. Enforce social distancing, limit employee capacity, and implement cashless transactions to reduce virus transmission in these high-contact areas.

- Buildings’ Fit-Out and Industrial Precommissioning. Onsite congestion reaches its peak during this phase, as several subcontractor teams work simultaneously on different tasks in a limited space. Alleviate this problem by limiting working-area capacity, carefully scheduling subcontracting teams, and regularly disinfecting sites to keep workers safe.

A Unique Opportunity to Accelerate Digitization

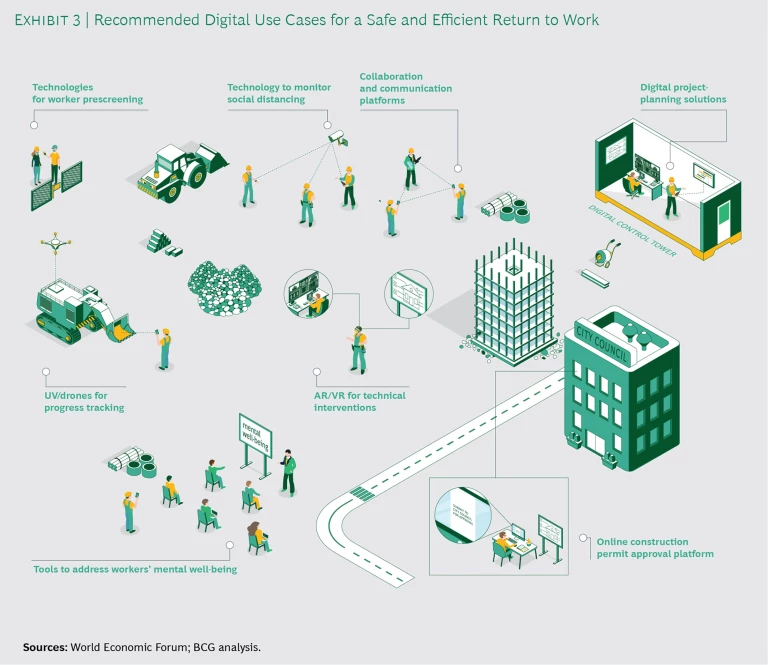

The crisis has provided E&C companies with the right incentives to accelerate their digitization efforts, as they pertain to both virus containment and process efficiency improvements. (See Exhibit 3.)

To monitor and prevent health and safety, companies should invest in prescreening, self-reporting, social distancing, mental well-being, and contact-tracing technologies. Setting up medical evaluation gateways at entry points will allow companies to monitor for COVID-19 symptoms by using the latest technology—including thermal-imaging cameras and handheld units. Combined with online questionnaires and digital health risk assessments, these technologies could go a long way toward preventing viral spread. In terms of mental health, some software providers currently offer well-being solutions to support employees’ sense of psychological safety and mindfulness.

At the same time, E&C companies are accelerating the use of surveying tools (drones, software-enabled cameras) to track social-distancing compliance and identify risks before they materialize, as well as the use of the Internet of Things (such as wearable sensors) to support contact tracing. Frontrunners are also exploring the use of artificial intelligence and analytics—to better support decision making and benefit from predictive capabilities—and the adoption of exoskeletons to enable heavy lifting with social distancing.

To automate processes and reduce human contact, E&C companies can increase the use of distance-friendly tools for collaboration. Task management apps, for example, reduce unnecessary contact among employees in the distribution of work. Similarly, combining virtual-reality applications with more traditional communications tools will help companies to better keep in touch with clients and invite visitors onsite only when necessary. Digital project management tools connect key stakeholders and provide managers with scenario analysis capabilities for resource allocation, activity planning, and quality control.

Additionally, companies are accelerating the use of digital war rooms and end-to-end integrated platforms for offsite and paperless project management, while benefiting from faster decision making and problem solving. Building information modeling deployment for remote coordination is also commonly explored by the industry under this unprecedent context.

Frontrunners are also investigating augmented-reality and virtual-reality technologies for remote inspections and visits; technical support so that specialists don’t have to visit the sites themselves; and communications with clients. Fostering offsite construction techniques (such as design for manufacture and assembly) is also considered by contractors as a good way to reduce human interaction across sites, while reducing waste and inefficiency in product manufacture and assembly.

Dialogue and Collaboration Are Now More Crucial Than Ever

The effective implementation of proposed health and safety measures and the acceleration of select digital technologies require thoughtful engagement and cooperation among multiple stakeholders. Clients especially should be involved in the adoption of new technologies, just as subcontractors should be regularly updated on the latest protocols. Unions are vital for ensuring that employees feel protected and for combating absenteeism, and regulators must be provided with regular feedback on the implications and outcomes of their policies.

Finally, the industry consensus is that companies should therefore consider creating crisis-management committees composed of different stakeholder groups to monitor progress, make decisions, and ensure productivity in their return to work.