This is the second of three pieces that build on our 2019 report, The Dawn of the Deep Tech Ecosystem. It is based on the new report, Nature Co-Design: A Revolution in the Making.

There’s another industrial revolution forming, and it promises to be at least as far reaching as the ones before it.

Because this revolution is taking shape across multiple technologies—game-changing advances in fields ranging from artificial intelligence (AI) to synthetic biology to nanoscience and quantum computing—its potential and reach are not immediately evident. It doesn’t even have an official name—yet.

We call this revolution “nature co-design”: the harnessing of nature's design principles and manufacturing capabilities to design and operate at the atomic level of organic and inorganic matter. It builds on the coming wave of deep tech innovation and encompasses a clear problem orientation, the convergence of emerging technologies and approaches, and the speed of the design-build-test-learn (DBTL) cycle. Its collective force and reach are about to become clear.

BCG has estimated that nature co-design will affect more than $30 trillion of economic activity over the next 30 years, the equivalent of 40% of current global GDP. The World Economic Forum has estimated that the disruption could lead to annual business opportunities worth $10 trillion and create 395 million jobs by 2030. For companies in such industries as pharmaceuticals, chemicals, agriculture and food supply, and advanced materials and manufacturing, the disruption is likely to be greater than anything that digital technologies have wrought.

This report looks at the gathering force of nature co-design, its effects on many value chains, and the way it fits within the broader great wave of deep tech innovation.

The Power and Reach of Nature Co-Design

To understand the potential impact of nature co-design, consider one of the world’s oldest and most valuable industrial processes, the Haber-Bosch process for producing ammonia and nitrogen fertilizers. Haber-Bosch, which hasn’t changed much since it went into production in 1913, is one of the main reasons farms can produce sufficient output to feed 7.8 billion people. But the process requires massive amounts of energy to convert atmospheric nitrogen into ammonia, consuming 3% to 5% of the world's natural gas supply and around 1% to 2% of the world's total energy supply. It is responsible for more than 1% of all CO2 emissions, and its N2O emissions are 250 to 300 times more potent than CO2 in contributing to global warming. More than 50% of the nitrogen washes off crops, contaminating water sources.

Despite countless efforts to improve the Haber-Bosch process, innovation has stumbled over incremental advances in thermocatalysis. This changed when deep tech ventures laid the groundwork for a new paradigm: designing microorganisms to replace chemical fertilizers. Two companies, Pivot Bio and Joyn Bio (a Ginkgo Bioworks–Bayer joint venture), are leveraging the principles of nature co-design. Both have used gene-editing techniques to design new organisms, which they then iterated through multiple DBTL cycles until they identified bacterial strains that can fix nitrogen directly on the roots of plants. By leveraging nature, Pivot Bio and Joyn Bio aim to reduce agriculture's reliance on nitrogen fertilizer, cut greenhouse emissions, reduce water pollution, and increase agricultural efficiency. Both could also disrupt the global ammonia market, which Grand View Research valued at $48 billion in 2016 and estimates will reach $77 billion by 2025.

There are many additional examples of nature co-design in action, spanning multiple sectors and encompassing many long-standing industrial processes. These include:

- Engineering yeast into a molecular assembly line to produce medicinal molecules (Antheia), plant-based milk and cultivated meat (Perfect Day, Memphis Meats), and programmable materials based on spider silk and cow leather (Bolt Threads, Spiber, Modern Meadow)

- Recycling and upcycling waste streams from industrial processes to brew fuel (LanzaTech), proteins (Kiverdi, NovoNutrients), and fibers and materials (Mango Materials, Polybion)

- Modeling living systems with computer-aided design tools to advance therapeutic applications (Asimov), improve protein design (Arzeda), create novel sensors (Koniku), and solve the 50-year-old challenge of predicting protein folding (AlphaFold2)

- Leveraging AI and automation to discover advanced chemicals and materials (Kebotix, IBM RoboRXN, Citrine) as well as to reduce the development time for advanced materials by unlocking the potential of nanoparticles (VSPARTICLE)

- Engineering and manufacturing advanced materials by drawing lessons from nature and applying them to electronic films (Zymergen), construction (Biomason, Ecovativ), advanced materials (Niron Magnetics and Sila Nanotechnologies), advanced manufacturing (Terapore), and even luxury (Heyaru)

Nature co-design promises to establish and maintain a very different relationship with nature than the one that companies have had for centuries, shifting the business innovation mindset from exploitative to generative. Instead of gathering and using nature’s output, or merely drawing inspiration from nature to solve problems, today’s entrepreneurs, scientists, and engineers are using a deeper fundamental understanding of the laws of nature to design and manufacture completely new types of products. Nature co-design solves big social and environmental problems and could become a primary driver of the global economy. According to the biotech accelerator IndieBio, nature co-design could add some $100 trillion to the global economy by 2040.

How to Harness Nature

The ability to harness nature’s design principles and use them in manufacturing platforms comes from advances in science and technology. Nature co-design is defined by four characteristics:

- The deep tech approach, including the DBTL cycle

- The ability to manipulate both inorganic and organic matter at the atomic level

- Use of nature’s design principles and manufacturing capabilities

- The creation of a transformational business opportunity with significant potential to advance sustainability

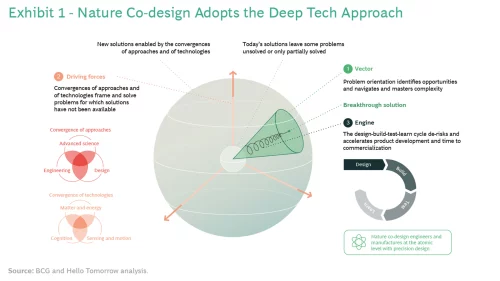

Adopting the Deep Tech Approach. Building on the deep tech approach, nature co-design combines science, engineering, and design to produce new solutions and products. It starts with a problem—such as increasing food production by fixing nitrogen on plant roots. To develop solutions, scientists rely on widespread access to advanced innovation tools, including DNA sequencing and synthesis, the CRISPR gene-editing technique and related technologies, precision fermentation and bioprocessing, AI and machine learning, and nanotechnology. They then iterate their initial solutions through the DBTL cycle to produce better innovations than were previously imaginable. AI in particular speeds the iteration process by making sense of data generated during the build and test phases to improve designs, until a working solution emerges. (See Exhibit 1.)

Manipulating Organic and Inorganic Matter. Since the first industrial revolutions, companies have relied on raw materials extracted from the earth to generate energy and build new materials. In the era of nature co-design, they will engineer organisms that consume feedstocks to manufacture desired products, or they will identify the properties needed for a certain material and work at the nanoscale to create them. Nature co-design goes beyond biology, incorporating fields concerned with nonliving matter—chemistry, nanotechnology, and the material sciences—to create the foundation of a new manufacturing paradigm. Rather than thinking of biology and chemistry as sets of constraints with a predefined dictionary of design principles and technologies, nature co-design applies engineering principles to organic and inorganic matter to design organisms and materials with desired properties to deliver specific outputs (such as molecules) or to behave according to predetermined or predesigned programs.

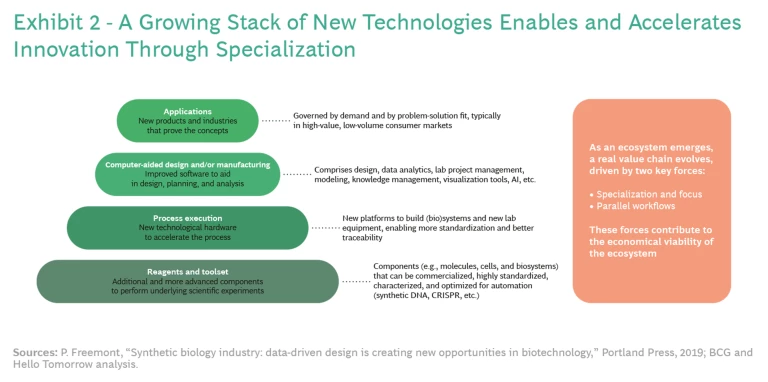

Synthetic biology, the most advanced nature co-design field to date, owes its growth and acceleration to the convergence of multiple technologies, including foundational technologies such as reading and writing DNA and gene-editing tools such as CRISPR. An expanding stack of new technologies—among them computational tools, organism engineering platforms, cell-free systems (which do not require organisms to manufacture end products), 3D bioprinting, and precision fermentation—enables companies to specialize and enter the market faster. Increases in computational power accelerate the digitization of biology. (See Exhibit 2.)

According to our preliminary estimates, investments in synthetic biology are growing steadily, with more than $95 billion invested from 2016 through 2020 (including private investments, mergers and acquisitions, minority stakes, and initial public offerings). The field boasts nature co-design unicorns such as Ginkgo Bioworks (which has raised nearly $800 million at a $5 billion valuation as of May 2020) and publicly traded companies such as Berkeley Lights, Checkerspot, and Twist Bioscience.

The field of advanced materials trails synthetic biology in development, but momentum there is building, and recent developments point to great potential and accelerated innovation. Nanotechnology gives scientists the ability to leverage atomic-scale forces to create materials with properties that can’t be found in nature. Use of the DBTL cycle to systematically design and manufacture nanoparticles that possess desired properties has the potential to disrupt countless industries.

Other technologies are coming into convergence as well. Kebotix uses a combination of robotics and AI to design new advanced materials; IBM RoboRXN, a cloud-based, AI-driven chemistry lab, is synthesizing new materials faster and more efficiently; and Riken, a 100-year-old Japanese company, recently announced the development of an algorithm designed to identify new materials.

Investor interest is growing as advanced materials research accelerates. For the period from 2016 to 2020, our preliminary estimates have identified $13 billion of disclosed private investments in advanced materials deep tech ventures. Pangaea Ventures, for example, is a venture capital fund dedicated solely to investment in companies seeking to produce advanced materials that solve fundamental challenges.

Leveraging Nature’s Design Principles and Manufacturing Capabilities. Nature co-design leverages and expands design principles and manufacturing capabilities that nature already possesses, making them more efficient and adapting them to human purposes. Researchers can use microbes and nanoscale forces to manipulate single atoms and build molecules with desired properties from scratch, using minimal energy.

Evolutionary pressure has forced microorganisms to become highly energy efficient. By understanding phenomena that are intrinsic at nanoscale, scientists can harness nature’s laws and mechanisms to create materials that have unprecedented properties. By engineering alternative selection pressures in the lab, they can accelerate natural selection to discover the best solution to manufacturing challenges.

For example, scientists can store more information in molecules than could ever be stored on solid-state chips or hard drives. They can create materials that are more flexible than Kevlar fiber and stronger than steel. They can produce magnets with exceptionally powerful electromagnetic fields. They can design nanoscale machines and self-assembling or self-healing items. Moreover, many materials created through nature co-design are recyclable, making the design processes inherently sustainable.

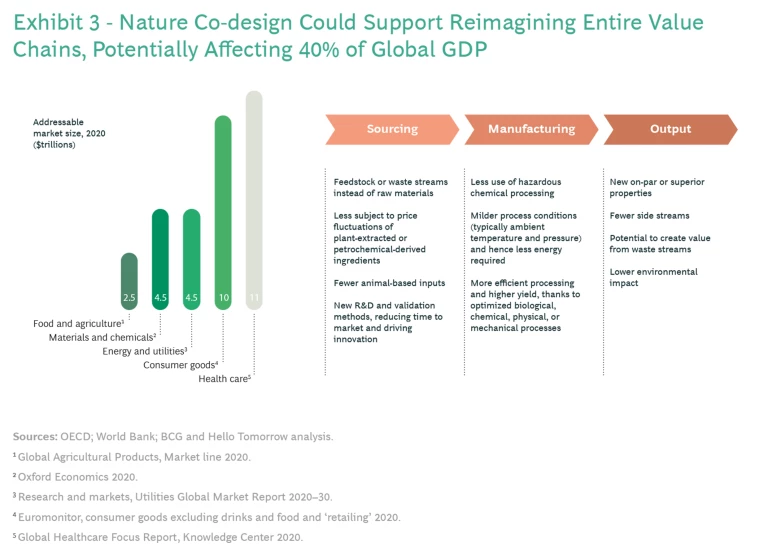

Seizing a Transformational Business Opportunity. Nature co-design represents an enormous business opportunity to catalyze the transformation to a sustainable future. Exhibit 3 details the addressable market in major nonservice sectors of the economy, which add up to more than $30 trillion, accounting for 40% of global gross domestic product.

If earlier phases of industrial development were about creating businesses that relied on the extraction and refining of raw materials, nature co-design will drive a fourth industrial revolution that opens value creation and redefines economics.

Rethinking Value Chains

Nature co-design offers companies an opportunity to rethink value chains and create true competitive advantage and real economic value. Its impact will be felt in three ways:

- Creating new sources of value and shifting existing value pools

- Meeting the material needs of society by focusing first on feedstocks rather than on extraction and raw materials

- Developing new economic equations with different scaling issues and operating and capital expense structures

Successful companies will build on new experience curves, leverage expanding scientific knowledge, and adopt a mindset that combines problem orientation and reimagination.

Shifting Value Pools. Nature co-design is not a single innovation but a set of principles unlocked through advances in science and engineering. Instead of breaking raw materials down into smaller building blocks and then recombining them, nature co-design builds materials from scratch, atom by atom, for an unprecedented level of manufacturing precision. Because biology is highly selective and can deal with a mixture of inputs, nature co-design also permits manufacturing from impure sources. This enables companies to make products from inseparable combinations of materials.

Nature co-design shifts the energy equation, too, causing processes that were previously uneconomical because of their required high-energy demands to become affordable. Put all of these principles together, and nature co-design can replace whole value chains (as in meat or dairy production) or substantial parts of a value chain (in textiles, for example). (See the sidebar.)

Replacing a Value Chain

C16 Biosciences is a startup that uses fermentation to produce an alternative to palm oil, a ubiquitous ingredient found in nearly 50% of all packaged consumer products, including pizza, doughnuts, chocolate, deodorant, shampoo, and toothpaste, to name a few. AZOCleantech estimates that palm oil is a $61 billion global market, but palm oil production has been and continues to be a major cause of rainforest deforestation. C16 Biosciences produces sustainable alternatives to palm oil that perform better and are cost competitive.

Similar examples of value chain replacement can be found in advanced materials from TeraPore and Sila Nanotechnologies. TeraPore uses nanotechnology to disrupt the market for virus filtration membranes—an important step in the manufacture of biologics, a market expected to reach $400 billion by 2025, according to Coherent Market Insights. The company uses advanced nanotechnologies to produce filtration membranes that are superior to incumbent products. TeraPore’s breakthrough involved replacing the commodity polymers used in competing products with newly engineered polymers capable of nanoscale self-assembly. In just four years, TeraPore has generated more than 25 designs for precise, tunable filtration products. Its main competitor needed 25 years of research and development to generate three designs.

Sila Nanotechnologies uses nature co-design to develop better materials for batteries, replacing the graphite anode on batteries with silicon—a cheaper, more abundant material. Sila Nanotechnologies’ first breakthrough increased battery energy storage density by at least 20%. The company started by addressing the mobile phone battery market, which delivers high value relative to cost. It is now entering the electric vehicle market and will eventually expand into the energy storage market.

Producers of advanced materials fully leverage the potential of nature co-design when they use atomic-level nanoscale forces to achieve properties that are not present in nature. This capability opens up a new paradigm, in which scientists define the properties needed for an application and create them at the atomic level, where quantum mechanics apply. For example, VSPARTICLE has developed technology to produce nanoparticles with preset specifications, without requiring manual work. The company is also working to reduce advanced material development times from 20 years to 2 years. Moreover, the unique properties of VSP’s nanoparticles make them suitable for high-value applications where industrial scale is not needed or desired.

Feedstocks First. Nature co-design shifts multiple critical industrial processes from linear and independent production chains toward a universal material ecosystem in which everything becomes a resource and waste from one production process can be a valuable resource for another.

Nature co-design feedstocks include sugar, corn, algae, carbon dioxide, methane, and any carbon-containing waste stream, such as cotton or even plastic. For example, startups LanzaTech and Mango Materials use waste as foundational material for value creation and locate their production facilities near sites that produce waste. LanzaTech uses industrial off-gases to produce fuels and chemicals. Mango Materials exploits methane to produce a biodegradable plastic that in turn can be used to develop fabrics.

It is also possible to upcycle waste streams without turning them into feedstock for microbes. For instance, CO2 from flue gas powers Agora Energy Technologies’ redox flow battery and serves as a key resource in nanomaterial designs at Carbon Upcycling Technologies.

New Economics. Nature co-design requires redefined economics. The need to scale from the top down instead of from the bottom up, the importance of designing to cost, and the necessity of understanding the economics of organisms characterize a new paradigm. Scientists can design microbes to increase yield and require less feedstock—or to grow faster, thus reducing capex and opex. Corporations must recognize the unique economics of nature co-design to create value and generate competitive advantage.

Although absolute scale plays a smaller role in nature co-design than in traditional industrial processes, the cost advantage generated through experience curves remains crucial. Achieving this cost advantage requires the modularization of infrastructure, the creation of standards, and the sharing of data (both positive and negative), so companies can profit from aggregated volumes and increased intelligence.

To get a sense of the impact, consider the radical shift in engineering and manufacturing that nature co-design entails. Instead of relying on capital-intensive processes and expensive energy to obtain desired outcomes, the economics of nature co-design reflect the precision and selectivity that comes from designing and manufacturing with nature. In this paradigm, scale and the steps necessary to leverage it economically take on a very different meaning.

For the past century or longer, the centralized aggregation of processing and refining created an intrinsic need for scale and large capital expenditures. High-cost facilities, such as refineries, represented huge investments and offered massive output capacities. But when we look at the world through a nature co-design lens, precision becomes the dominant dimension. Design and manufacture start at the nanoscale and build with atomic precision. For example, a refinery today might cost $1 billion to build and produce 30 million liters of oil a day. In contrast, a small bioreactor could cost $100 million to build and produce the equivalent of 10,000 to 100,000 liters of oil per batch—but the value extracted is on a different scale because a few hundred liters could produce medicinal molecules worth hundreds of thousands of dollars per production run. New value creation models and the replacement of raw materials with feedstock alter the size of an optimal plant.

The result is a need for smaller, more modular, and intrinsically flexible facilities. Companies can replace large centralized plants with distributed networks of reprogrammable manufacturing sites, since the only things that move from place to place are digitally codified. Large buildings, physical pipelines, and trucks and ships all become less important. As smaller, less sophisticated infrastructure reduces the need for up-front allocation of financial resources and decreases the time required to build large sites, new ventures can reach the market faster without burning through their limited cash reserves before starting to generate revenue.

At the same time, choosing and procuring feedstock become strategic operating expenses that affect cost along multiple dimensions, not only as inputs but also as outputs. Location of production becomes an important variable because it can directly affect the cost of the feedstock, especially if the feedstock consists of waste from other processes. The cost of electricity can play a crucial economic role, representing up to 15% of total opex. When companies merge nature co-design with the ongoing trend toward a descaled and distributed energy infrastructure, moving toward near-zero-marginal-cost power generated by renewables, production infrastructure becomes smaller, localized, and distributed, but also more flexible and more resilient.

Working out the economic equations involved in nature co-design also requires mastering the nonlinear scaling mechanisms that operate at the atomic level. Microorganism growth or development typically scales in an S-curve over time, as the microorganisms do not behave in the same ways at initial small volumes and at target high volumes.

Scientific Knowledge Has Never Been More Important

Nature co-design is at the very beginning of its journey. According to the BioGenome Project 2018, 80% to 90% of the world’s species remain unknown to science. A great deal of foundational knowledge has emerged from the genomic sequencing of the 10% to 20% of species known to us, facilitating advances in agriculture, medicine, and biology. But we are only a few years into that revolution.

Chemistry offers virtually infinite degrees of freedom for output design and creation—and generates increased complexity in the scientific innovation process. The number of atomic combinations is vast. There are approximately 1060 small organic molecules of 70 atoms or fewer, but the largest public database contains only around 70 million (7 × 107) synthesized molecules to date. Moreover, the impact of chemistry and materials science arises from the properties that these atoms and molecules achieve. Nanotechnology produces properties that were unattainable through traditional larger-scale structures. The property changes of nanomaterials derive from quantum forces that are intrinsic to the nanoscale. Again, science must advance to pave the way for materials with properties that do not exist in nature.

Quantum computing is likely to boost the discovery and design of molecules and materials. It should be able to compute highly complex algorithms and manipulate massive quantities of data on atomic states at unprecedented scales and speeds.

Business leaders today need to realize that science is still far from fully understanding the complexity of nature and that the journey of discovery is only just beginning. Science will be the next transformational dimension, much as digital technologies are today for most industries. As such, it will pose a serious challenge for industries that have underallocated funds to R&D.

Problem Orientation Combined with Reimagination

The ability to rethink value chains is a feature of a problem orientation mindset. To change the status quo, companies must move beyond current solutions. To broaden the scope of available options, they need to examine core problems and focus on value pools that could shift if the convergence of technologies and approaches unlocks new options.

Imagination in solution design must move away from what is immediately available to consider what could be there instead. Nature co-design is no mere incremental step: it requires embracing an entirely different way of thinking, adopting a nonreductionist approach to nature, establishing a robust ethical framework to navigate future ambiguity, and managing risks. Owing to the intrinsic complexity of organic and inorganic matter, many unknowns remain. Rather than reducing complex problems to smaller, simpler component issues, researchers should see them as a whole—if for no other reason than to uncover hidden side effects.

Ethical questions may legitimately arise when potential second- and third-order consequences are at stake, especially in the adjacent fields of life sciences. The scientific and business communities must work together to combat fears and disinformation that may threaten public acceptance of transformative moves. Institutions should anticipate the need to construct an ethical framework to lead ethical discussions and help navigate natural ambiguity.

As with other aspects of deep tech, most corporations cannot master nature co-design on their own. They need to participate in ecosystems in order to play. Nature co-design requires that governments and institutions continue to support and promote basic research while helping to build the infrastructure and defining standards needed to undergird a more resilient distributed industrial base. Governments and institutions will also play a crucial role in defining regulations and ethical norms.

Corporations, investors, and governments are the three major stakeholders best positioned to drive and benefit from nature co-design, and they have already begun preparing for the revolution. Although much work lies ahead, opportunities abound for those willing to lead.