Disruptive technologies are changing operations and manufacturing: computer vision, the industrial metaverse, edge computing—the list goes on. But with so many tools, where do you focus in order to foster growth and optimize productivity? BCG combines deep expertise in technology and operations—showcased through immersive experiences—to help companies visualize, and quicken, their path to operational excellence and digital transformation.

How BCG Sparks Innovative Operations and Manufacturing

We start by inspiring, demonstrating the power—and innovative applications—of new operations technologies. Next, we assess, determining the maturity level of existing operations and zeroing in on the pain points—and opportunities—that matter most. Then we enable, helping teams develop the skills and capabilities needed to harness the power of technology. Finally, we engineer tailored solutions and implement them at scale to future-proof clients’ operations.

The Innovation Center for Operations’ End-to-End Approach

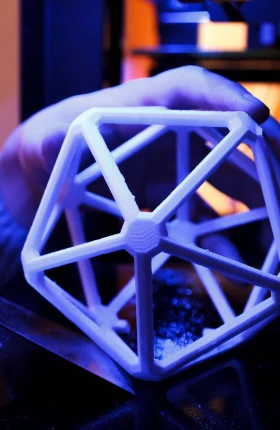

- Physical and Digital Factories. Experience the power of innovative manufacturing firsthand at the nine model factories of the Innovation Center for Operations, strategically located across North America, South America, Europe, and Asia. These model factories offer a unique opportunity for hands-on testing, idea exchange with experts, and invaluable insights on deploying new manufacturing technologies. For those unable to visit in person, our digital factories provide an immersive experience accessible from desktop and mobile screens, ensuring accessibility and convenience in exploring the potential of advanced manufacturing.

- Emerging Tech Demos. We use proprietary software to create best-in-class immersive demonstrations of new manufacturing, biopharma, and operations technologies. Our cloud-based system lets us replicate a client’s own processes and spotlight opportunities to drive digital transformation and operational excellence.

- Co-development Labs. After helping companies identify opportunities to innovate, we help them build the solutions. Our co-development labs—operating in partnership with leading academic institutions—are a venue for collaboration and a catalyst for value creation. Working with our clients, we turn a promising idea into a compelling proof of concept.

- Best Practices and Benchmark Apps. Through proprietary tools, we help companies see where they stand on innovative manufacturing. Compass Performance Benchmarking by BCG lets companies compare themselves to peers on nine functions, including operations excellence and supply chain management. Pathfinder—another key diagnostic—features topic-specific health checks that assess maturity levels, suggest improvement measures, and note potential savings.

- Enablement Curriculum. Supplementing our immersive experiences are learning materials—divided into 23 modules—on a spectrum of topics related to manufacturing technologies and innovation in operations. Drawing on ideation methodologies, insights on scaling, and expert discussions on an array of use cases, our curriculum fosters knowledge—and results.

- Global Collaborations. Unique to the Innovation Center for Operations is our global network of partners: industry leaders, top academic institutions, and cutting-edge technology vendors. These collaborations give us access to the advances, resources, and expertise that fuel innovation—and help us engineer tailored solutions that maximize efficiency, productivity, and quality within the manufacturing value chain. The roster is long and includes AWS, Nvidia, Siemens, WSU, Simtech, and WZL.

Our Clients’ Success in Innovative Manufacturing

Our Innovation Center for Operations Leadership Team

Explore Our Insights on Innovative Manufacturing and Operations