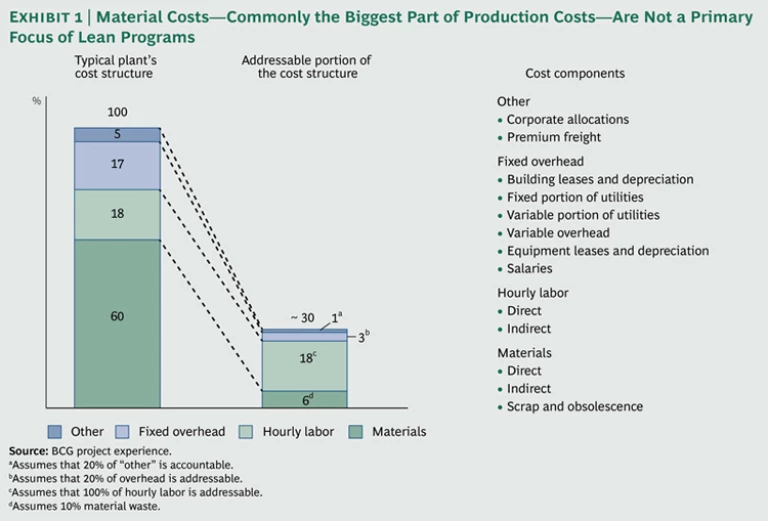

Many manufacturers that have applied lean concepts to their operations find that although they do achieve significant savings, their production costs remain high. This is, in most cases, attributable to material costs, which, depending on industry can range from 60 to 80 percent of total production costs. (See Exhibit 1.)

The challenge for these manufacturers is to discover how to extend lean concepts and practices beyond the walls of their own factories. The most effective way is to forge links with key suppliers on the basis of lean principles. In addition to yielding cost savings, this kind of collaboration can form the foundation of a profitable strategic partnership. More than simply an approach to eliminating waste in procurement, creating such relationships means leveraging existing lean techniques to the fullest and using them to transform a manufacturer’s entire supply chain.

The overriding goal is to create a spirit of partnership by identifying the potential for mutual improvement on a fair and collaborative basis. Although many manufacturers approach their suppliers seeking ways to reduce material costs, typical efforts produce only short-term savings. Few form the basis for sustained, close collaboration. Building trust comes first. If this is done effectively, savings and other benefits will follow. Because those benefits extend beyond immediate savings, it can be advantageous to form a lean-based partnership even with suppliers in low-cost countries.

The best results have been achieved using a three-step integration process, which begins with optimizing the way information and materials flow between supplier and manufacturer. It extends to the way the supplier produces and can lead to collaborative product design and redesign. Ultimately, the process involves the full integration of a key supplier into a lean culture of continuous improvement. The main focus should be on enhancing supplier innovation and responsiveness—along with cost reduction over entire product life cycles—rather than on quick savings. Supplier integration has been achieved successfully by major consumer-product manufacturers, especially in the automobile industry. Toyota is one of the notable examples. (See Getting to Win-Win: How Toyota Creates and Sustains Best-Practice Supplier Relationships, BCG Focus, September 2007.)

The Three Leagues of Lean

As in football, companies at different stages of lean development play in different leagues. Companies need to be honest with themselves about their current league status and which league they want to be in. (See the exhibit below.)

Lean Local League. This is the initial level of lean development. Companies in the local league have established lean programs in some but not all of their factories. Losses are identified in four areas (equipment, labor, quality, and materials), and lean tools (flow and availability, quality, organization, and cultural-transformation tools) are used to eliminate those losses. Local-league companies use lean techniques to get quick wins with bottom-line impact.

Lean National League. Companies in this league—one step up—have a standardized lean-production system for all factories; and common tools, principles, processes, and metrics are applied consistently across the manufacturing organization. National-league companies’ dynamic approach to governance systematically renews itself on a regular basis so that continuous improvement is woven into the fabric of the lean program.

Lean Champion League. At the top level, companies get the full benefit of lean. Such companies have extended lean concepts and practices beyond manufacturing to all aspects of the organization. They have built a culture of continuous improvement into their engineering, R&D, and administration. Champion-league companies are ready to extend lean techniques to their suppliers.

Before beginning the process, a manufacturer should analyze its own level of lean development and ambitions for the future. (See “The Three Leagues of Lean.”)