Carbon capture is potentially on the cusp of acquiring a major role in meeting the world’s climate change mitigation goals. The challenge: how to transform this expensive, 40-year-old niche technology into one that is mainstream and cost competitive.

Carbon capture, utilization, and storage (CCUS) is one of just a few technologies that can decarbonize large, stationary emitters of CO2. CCUS advocates agree that one important means of minimizing the costs of CCUS will be the development of large-scale geographical hubs, in which multiple emitters are connected to a shared CO2 transportation and storage network. These hubs can help open up CCUS to a wide range of emitters. They also offer cost advantages thanks to their proximity to geological storage and existing pipeline infrastructure as well as the scale effects from including a large number of emitters.

Our analysis of CO2-emitting industries and storage capacity worldwide indicates that small, localized networks, comprising just a handful of emitters, could provide a key route to the commercialization of CCUS and the eventual development of large-scale hubs. By cutting average carbon abatement costs in promising clusters to less than $100 per metric ton—in some instances, up to an 80% reduction over standalone CCUS projects—small networks would go a long way to delivering the capacity needed to reduce global warming. And by unlocking scale and learning curve benefits, they would make low-concentration carbon capture, which is the holy grail of CCUS, a viable option.

Low-Concentration Capture Needs a Capacity Boost

Industries that are candidates for CCUS technology can be divided into two groups: those with high concentrations and those with low concentrations of CO2 emissions. For industries with highly concentrated CO2 emissions, such as natural gas processing, ammonia production, and ethanol production, the costs of carbon capture are relatively low. Recent tax incentives and policy initiatives in the US and Europe are now making CCUS commercially viable in these sectors.

But by far the largest number of stationary CO2 emitters are in industries with low concentrations whose capture costs are consequently high, particularly coal- and gas-fired power plants. We estimate that between 80% and 90% of captured emissions would have to come from such low-concentration sources in order to limit the rise in the global temperature to well below 2°C—the goal of the 2015 Paris Agreement.

By unlocking scale and learning curve benefits, small, localized networks of emitters would make low-concentration carbon capture a viable option.

As a result of technological breakthroughs, carbon capture costs in low-concentration applications are declining. Recent developments by Svante, Ion Engineering, and the Petra Nova project in the US have reduced capture costs significantly using amine scrubbing and solid-sorbent technologies. Our research indicates that low-concentration capture costs could fall below $30 per metric ton, from more than $70 per metric ton today.

However, this depends on low-concentration CCUS capacity increasing from less than 5 million metric tons currently to at least 1 gigaton, thereby allowing low-concentration carbon capture to benefit from economies of scale and learning curve effects similar to those seen in other industries. We believe the development of CCUS capacity via localized networks, which share CO2 transportation pipelines and storage, is vital for reaching this capacity goal.

Small Networks Deliver Large Benefits

In addition to capture costs, the costs of transporting and storing CO2 are important components of the overall cost of CCUS and can vary widely. The length, size, and capacity utilization of the pipelines used to transport emissions all have cost implications.

Transportation expenses range from under $5 per metric ton (when an emitter is located close to storage) to well over $100 per metric ton. Storage costs are generally between $2 and $11 per metric ton, depending on the depth of the well and whether it is a preexisting or a new facility. Using captured CO2 in enhanced oil recovery (which relies on the gas to increase the amount of oil extracted from a reservoir) can also improve CCUS economics.

As a result of technological breakthroughs, carbon capture costs in low-concentration applications are declining.

BCG Gamma, our data science and advanced analytics unit, has created a proprietary tool to gain an in-depth understanding of the costs of CCUS technology when used in different locations. The tool has three parts: a clustering component that uses two algorithms to combine emitters into networks that maximize transportation efficiencies (based on their proximity to one another) and minimize total system costs; a storage matching algorithm that links emitters to the lowest-cost storage and enhanced oil recovery options; and an economic optimization component that identifies the marginal costs of adding CCUS to different emitters within a network.

Our model confirms that the proximity of CO2 emitters to storage or utilization is the key factor in keeping CCUS costs low. But it also shows that organizing emitters into small networks is a highly effective way to reduce the cost of deploying CCUS. We found that several factors contribute to lower costs when emitters form networks.

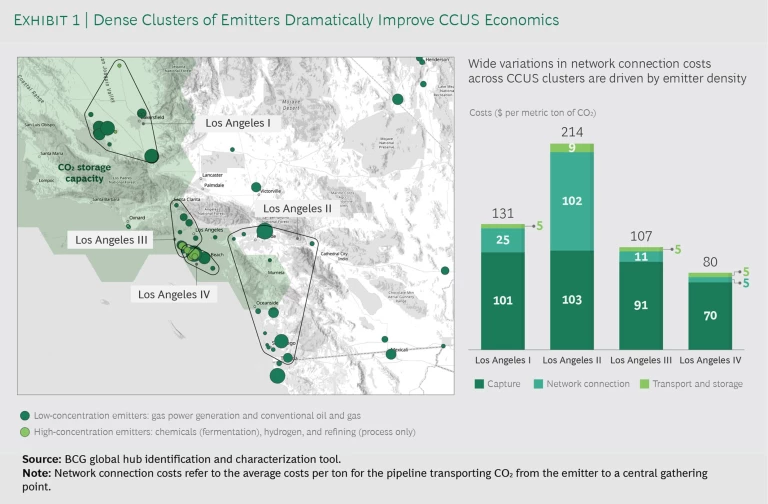

Denser clusters of emitters benefit from significant cost advantages. Southern California, which has abundant CO2 storage, is a good example. (See Exhibit 1.) The densest cluster of emitters is within Los Angeles itself (Los Angeles IV in the exhibit) and generates 8 million metric tons of emissions annually. If emitters there were to form a CCUS network, our model indicates that the average cost of transporting and storing CO2 (including network connection costs) could be $10 per metric ton. The neighboring San Bernardino area (Los Angeles II) has a far more diffuse cluster of emitters but with similar combined annual emissions of around 6 million metric tons. As a result of this cluster’s lower density, average transportation and storage costs would be around $110 per metric ton.

The number of emitters and the order in which they join the network are also significant factors in reducing overall costs and making CCUS more commercially viable. Our model indicates that combining multiple emitters in a network can deliver significant economies of scale and reduce the weighted average of the network’s CO2 transportation and storage costs by as much as 80% compared with standalone CCUS projects.

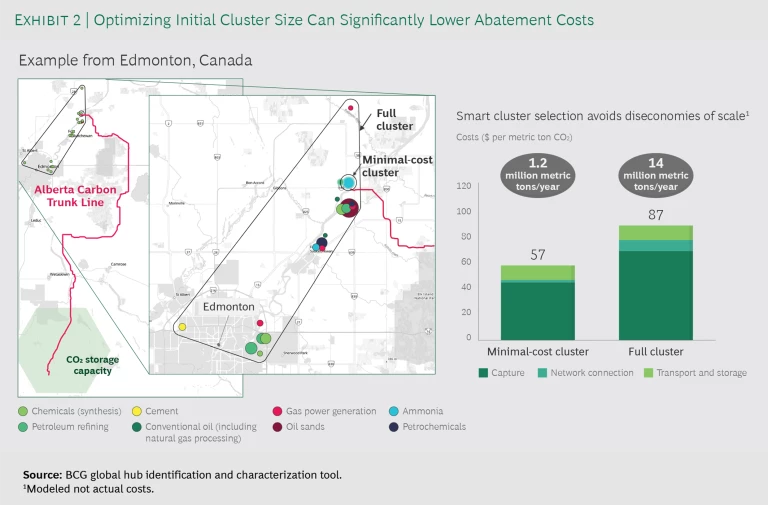

What’s more, we found that sometimes only a small number of emitters are needed to achieve the lowest average carbon abatement (capture, transportation, and storage) costs for a network. In networks that have the potential for low carbon abatement costs, this point can be reached with just two to three emitters producing 5 to 7 million metric tons of CO2. between them annually. After this point, the network’s average abatement costs start to slowly rise as more widely dispersed emitters are included.

Because small, localized networks have significant cost advantages over individual emitters, they can bring down barriers so that others can join. A handful of high-concentration emitters with low capture costs can form a network. Then, once the network is up and running and early-stage technical risks have been resolved, low-concentration emitters (which are larger and offer additional economies of scale in transportation) can join at a lower incremental cost.

Current projects in Edmonton, Canada, are starting to show how networks reduce key CCUS costs in practice. (See Exhibit 2.) Carbon capture technology has been installed at three high-concentration emitters (two oil refineries and an ammonia plant), and a pipeline—the Alberta Carbon Trunk Line—has been built to transport CO2 for storage and use from two of them. Our model indicates that by including the optimal mix and number of emitters at the outset and avoiding significant diseconomies of scale by preventing more dispersed emitters from joining, this emerging network could deliver average transportation and storage costs that are half those of a larger and less efficient network.

Opening Up New Regions

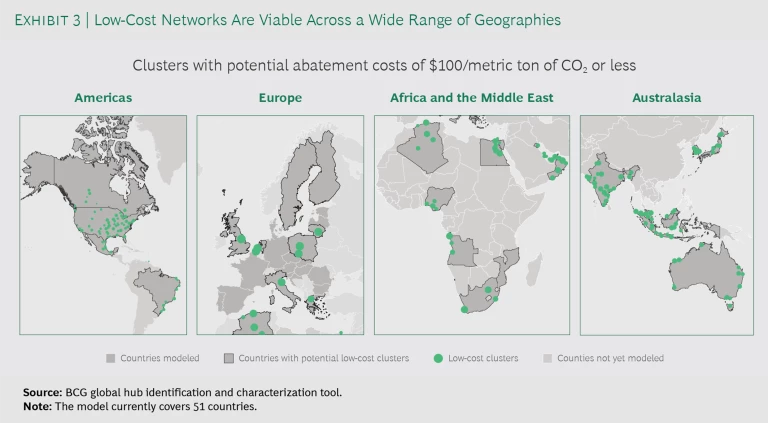

Our research suggests to both kick-start the development of large-scale CCUS hubs and introduce low-cost networks outside of potential hub regions. Across the geographies assessed, we estimate that there are nearly 200 clusters that can be developed into low-cost networks with average carbon abatement costs below $100 per metric ton, based on the current costs of carbon capture. (See Exhibit 3.)

Many of these clusters are in geographies that are less frequently considered for CCUS projects. These include Greece, Poland, Lithuania, India, and South Korea. Opportunities also exist in oil-and gas-producing countries outside of regions with the potential for large-scale CCUS hubs, including Nigeria, Angola, Azerbaijan, and Trinidad and Tobago.

Together, these clusters could reduce CO2 emissions by more than one gigaton per year, with abatement costs below $100 per metric ton based on the current economics of CCUS. This reduction would be a major step toward delivering the 4 to 6 gigatons per year that the International Energy Agency estimates must be abated through CCUS by 2040 to keep global warming well below 2°C. And through scale and learning curve effects, the clusters would also enable further cost improvements in low-concentration carbon capture technologies.

Action Steps to Promote CCUS Networks

The development of low-cost networks will depend on support from multiple stakeholders, including the following:

- Governments. Policymakers will need to think about how to promote the development of local networks that integrate different emitters, rather than viewing CCUS purely in terms of individual projects. They should consider tax and other financial initiatives that foster innovation and promote investment in specific local regions. These initiatives will likely also benefit employment and job retention strategies in industries that might otherwise be hard hit by energy transitions.

- Emitters. Industries that emit CO2 should examine the feasibility of using CCUS and determine whether any of their plants could be combined with those of other emitters to form a network. They can start by considering whether there is scope to build strong local partnerships and regulatory and policy support to develop CCUS infrastructure. They may find that the cost structure of CCUS is radically different when they work in partnership with others rather than pursuing projects on their own.

- Investors. The investment community increasingly needs to assess the competitiveness of industrial companies and their specific assets in a lower-carbon future in order to identify the possible danger of stranded assets. But they should factor into their calculations the potential for low-cost CCUS networks to mitigate those risks and identify opportunities to develop CCUS networks. In the future, assets at risk of being stranded will be determined not just by the scale of their emissions but also by the relative cost competitiveness of abating those emissions.

Carbon capture technology may be about to realize its long-mooted potential. The creation of small networks of emitters sharing CO2 transportation and storage infrastructure can play a central role in achieving that goal and help to bring abatement costs down sharply. Such networks could also extend the use of CCUS into low-concentration industries, a vital step toward building the capacity needed to reduce global warming. While the long-term future of CCUS may be in large, geographically concentrated hubs, the development of small, localized networks is an important first step.

We are grateful to Ben Clark and Valeria Boesso of BCG Gamma for their expertise and help in building and deploying our CCUS cluster tool. We would also like to thank Julio Friedmann, of the Columbia University Center on Global Energy Policy, and Cameron Hepburn and Steve Smith, of the Oxford University Smith School of Enterprise and the Environment, for their expert guidance. Finally, we thank the Oil and Gas Climate Initiative for sharing its expertise, notably on hub economics, and supporting our work. This article builds on the insights BCG has gained through its support of OGCI Climate Investments in developing an approach to catalyzing deployment of CCUS at scale and to building a portfolio of CCUS projects. In addition, we conducted work for OGCI’s CCUS KickStarter program, which aims to leverage economies of scale on CO2 transport and storage and make CCUS commercially viable.