Fashion, an industry of craft and creativity, needs to go digital both to survive attack and to thrive in the next decade. CEOs know it. Designers know it. Investors are starting to ask questions about it. Yet few if any of the major fashion brands have fully digitized their value chain from planning to shelf. Instead, they are testing and piloting different approaches. Limited in scope, these approaches are also limited in their potential to generate value.

Going slowly is understandable but ultimately shortsighted. As a “hit” business, fashion companies are under constant pressure to release new collections. Against the weight of everyday operations, digital transformation can seem daunting even if fashion executives recognize that their business is too reliant on manual steps, too prone to error, too inefficient, and too slow.

These underlying conditions cannot persist much longer. Digital is not disrupting just the usual suspects such as media and financial services and retail, where Amazon is a force of its own. Digital is also starting to disrupt industries with physical offerings, such as fast-moving consumer goods and automotive.

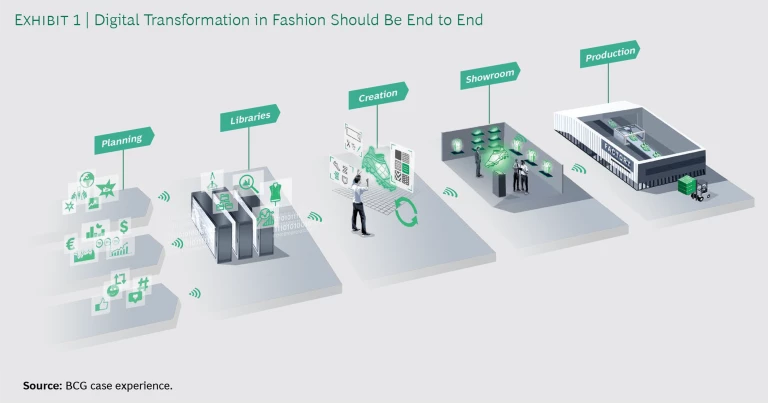

To meet the challenge and capture the opportunity of digital, fashion companies need to transform from end to end. Work at every step in the value chain will be affected, starting with planning. (See Exhibit 1.) A designer will work in 3D by picking up library components such as patterns and zippers. The design is then passed to the factory as a 3D file, so finalization does not require the time-consuming back-and-forth inspection of finished samples. Corporate customers can view the detailed 3D asset in a virtual showroom. The factory does not manufacture a physical product until then, quite a revolutionary step for the industry.

The whole of this end-to-end transformation is greater than the sum of its parts. A fashion company that digitized only marketing and sales, for example, would not develop a 3D asset to display in the virtual showroom and so could not gain efficiencies by reducing the number of physical samples.

Why Digital in Fashion

An end-to-end digital transformation is the most effective way to address the key priorities of fashion companies over the next several years: creating compelling designs that capture the next trend while operating faster and more efficiently.

Consumer Centricity. Fashion innovation remains rooted in the past and based on gut and guesswork. Digital will help bring design and the consumer closer together. Designers can gain data-based insights into trends and consumer behavior. This tightening loop can help fashion brands anticipate the next big trend and increase the amount of merchandise they sell at full price.

Time to Market. Even in an era of fast fashion, time to market is a competitive advantage. An end-to-end digital transformation can squeeze the calendar by up to 40%. When a piece is designed and built from the ground up in digital form, with a common set of tools and libraries, mistakes and do-overs fall sharply. Virtual fittings reduce the need for time-sucking trips to the factory because the factory has the exact designs it needs to develop, engineer, and manufacture products.

Long-Term Efficiency. Companies should digitally transform to generate long-term value, not necessarily short-term savings. It takes time and resources to transform from 2D to 3D designs. That short-term investment will eventually pay for itself many times over because digital workflows are standardized and automated. One key benefit is that companies can cut down on physical samples by as much as 70%, helping to reserve factory capacity for finished products and shrinking the industry’s environmental footprint. In addition, at the end of a digital transformation, we estimate, fashion companies will likely need up to 20% fewer people in the end-to-end creation process. These savings can be re-invested into product creation and quality.

Companies should digitally transform to generate long-term value, not necessarily short-term savings.

Reaching the Digital Summit

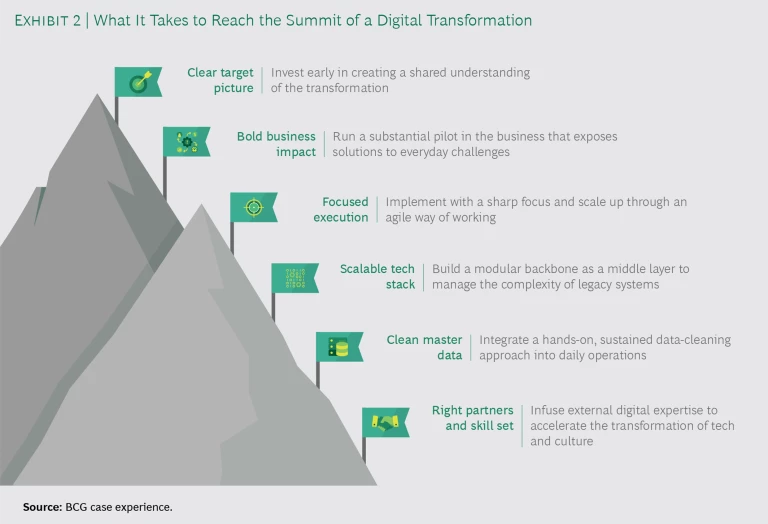

Digital transformations are long and challenging journeys into the unknown. In that way, they are similar to expeditions to pioneer a new route up a Himalayan peak. Both are complex, drawn-out affairs that require a mix of ambition, execution, skill, equipment, training, and support. Here are the elements of a successful journey. (See Exhibit 2.)

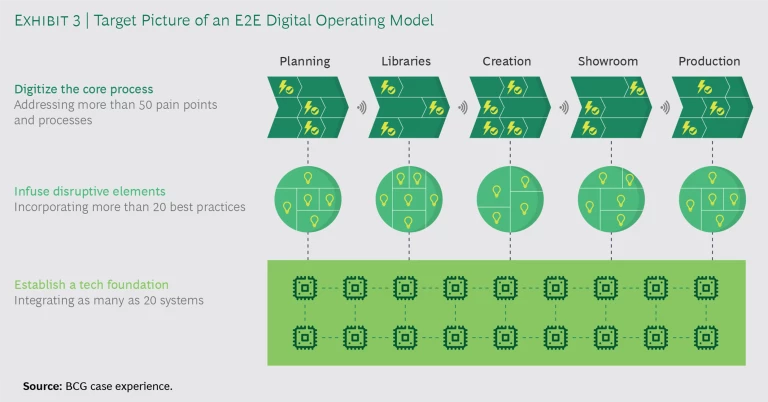

Clear Target Picture. All employees need a specific vision that links strategy, ambition, and action—not a vague aspiration to become digital. This preliminary work of identifying and building support for a big, bold idea is critical. It is what sustains a digital transformation. When people believe in and collectively agree on what they are doing, teams push through obstacles and work more effectively. The vision cannot be vague. It should paint a picture of a new operating model that addresses current inefficiencies (we identified more than 50 for one fashion brand) and is built on a foundation of digital and technical innovation. (See Exhibit 3.)

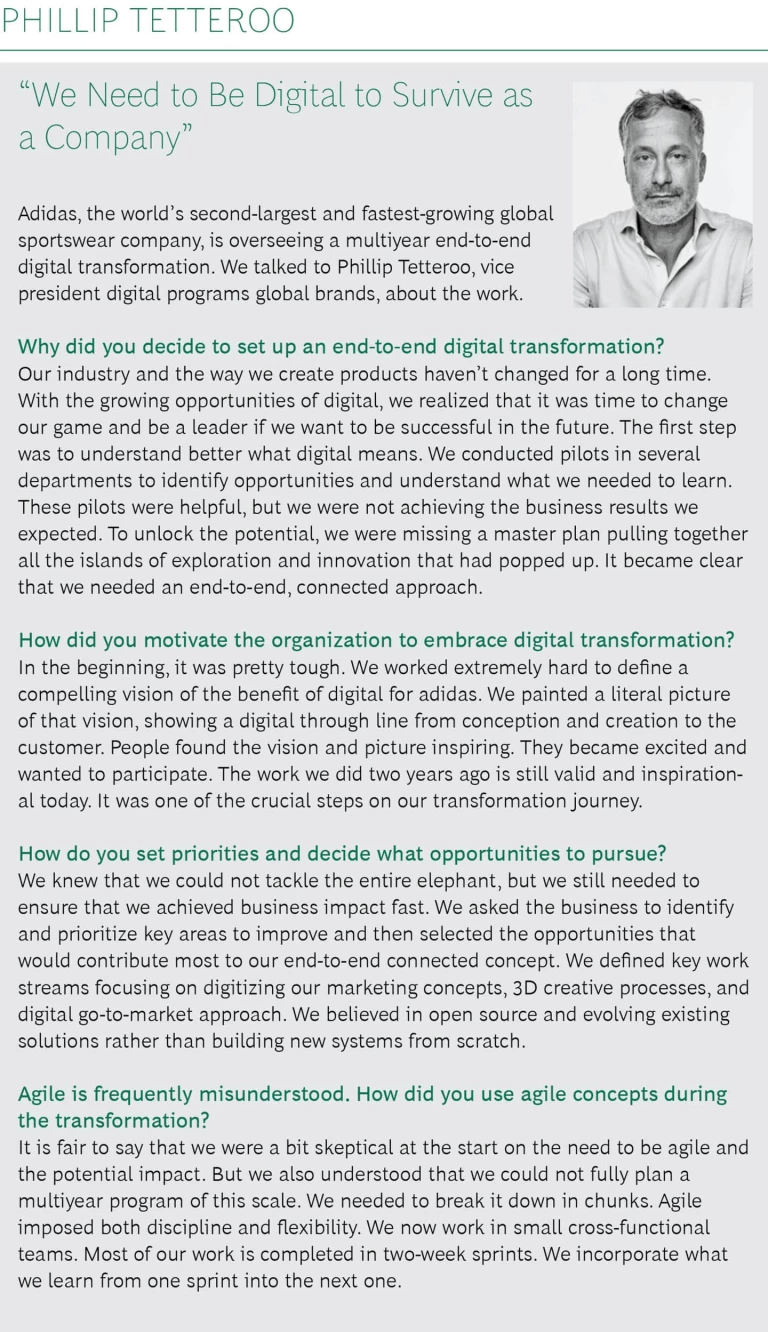

Bold Business Impact. Companies often make one of two mistakes in digital transformation. They create a standalone digital business that operates outside of the traditional organization, or they focus their efforts within specific functions that are limited in scope and business results. (See “We Need to Be Digital to Survive as a Company.”)

Digital transformation is not lab work. It only counts if it makes a meaningful difference in value creation, so companies need to put a chunk of the business in play by transforming an end-to-end process. Ideally, they would select a large, important business unit with an entrepreneurial bent to run as a digital end-to-end enterprise. By operating an entire business digitally from end to end, executives will see exactly what works in the real world and what needs modification.

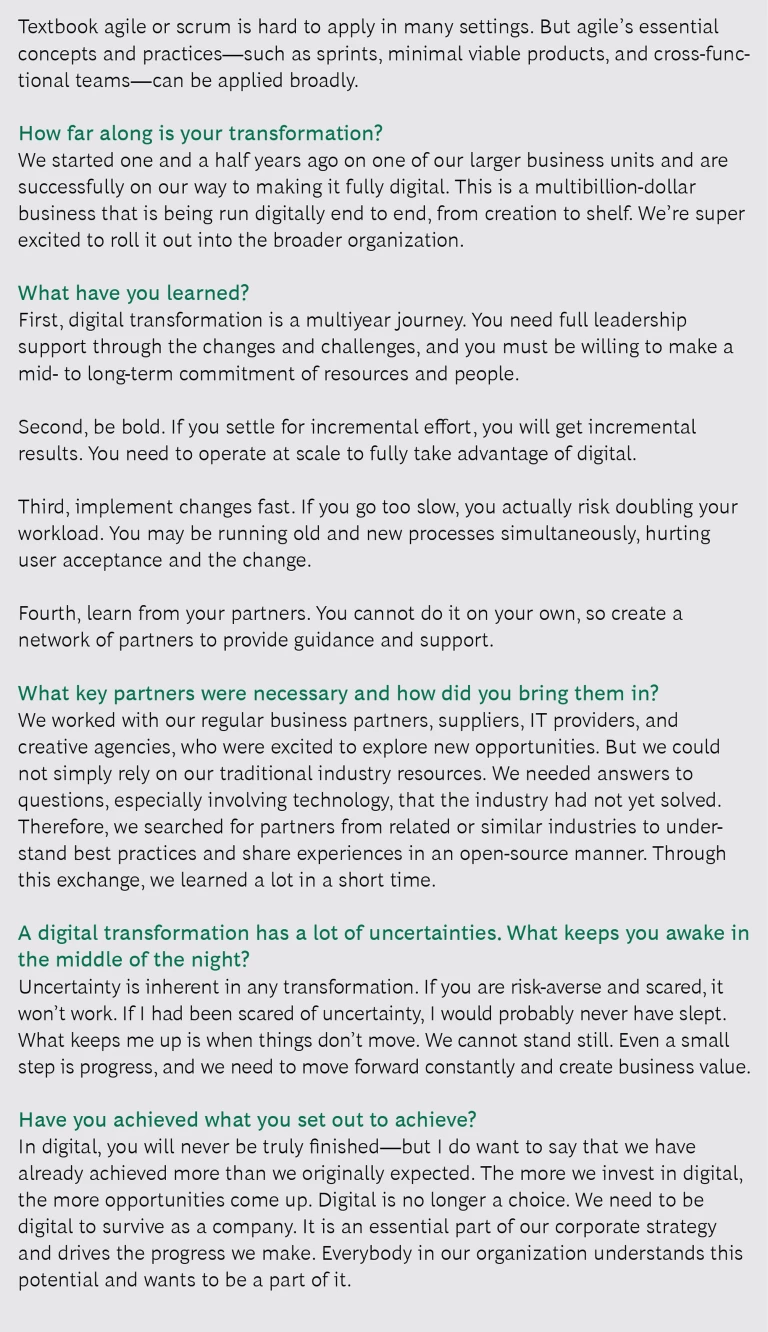

Focused Execution. Mountaineering teams break their expeditions into stages to simplify the trip and demonstrate progress. This staged approach also works well as a way to deal with the complexity of digital transformation. Once a company has selected a substantial part of the business to use as a pilot, it should start with a few high-potential levers and build on those early efforts rather than introduce digital technologies and workflows with a big bang. Agile and other cross-functional, sprint-based, test-and-learn approaches are effective ways to break a transformation into manageable stages, create quick wins, and sustain progress. (See Exhibit 4.)

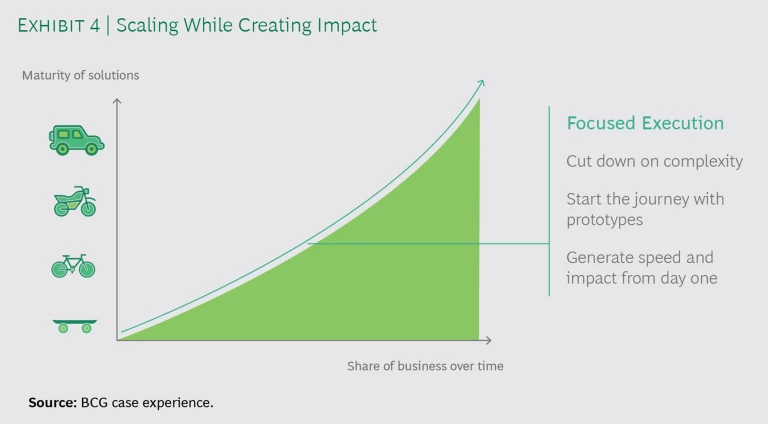

Scalable Tech Stack. While digital transformation is ultimately a transformation of the business and ways of working, it is built around a technological and data backbone. This backbone should be cloud-based, flexible, modular, and scalable. It should serve as a single source of data on customers, products, and processes and manage workflow step by step as a design takes shape and emerges as a finished item.

Ideally, this backbone should act as a layer between legacy systems and modern state-of-the-art technologies with a strong set of APIs connecting the old and the new. (See Exhibit 5.) This approach allows companies to take advantage of modern technology without having to abruptly ditch their legacy systems. They can instead phase those systems out gradually.

Clean Master Data. Data is the muscle fiber of a digital transformation. It needs to be in shape. The data at many fashion companies continues to be out of date, proprietary, and sometimes still in analog form. The work of cleaning old data and creating clean new data sounds like a technology challenge, but it’s ultimately a business challenge. Data needs to be entered correctly at its source during day-to-day business activity. Companies need a standard data-entry process that is intuitive and based on simple user interfaces, such as dropdown menus. They need to train employees in the importance of getting data entry right the first time, and they need an automated process to spot-check data for quality and consistency.

The work of cleaning old data and creating clean new data sounds like a technology challenge, but it’s ultimately a business challenge.

Right Partners and Skill Set. Companies need to build momentum quickly in their digital transformations. It’s not easy to develop the skills required to introduce new technologies and agile ways of working. External parties such as IT experts, 3D design agencies, and coaches can play constructive roles.

It is often helpful to bring in a lead external partner who pulls together and aligns the strands of work into a transformational fabric. More than a coordination role, this partner should be solving problems, keeping the original end-to-end concept intact, ensuring progress, and speaking to senior leaders.

Over time, companies must develop the required talent and skills. They will need to train and upskill employees in 3D design capabilities and other technologies, and they will likely need to bring in external candidates.

While most fashion companies are preparing for incremental change, the fashion industry—with its decades-old process of creation, manufacturing, and commercialization—is ripe for fundamental disruption. Fashion companies need to be faster, more efficient, and more sustainable, while selling more merchandise at full price. The best way to accomplish those goals is through a new operating model built around end-to-end digital workflows.