Generative AI is projected to grow faster in health care than any other sector—and leading medtech and pharmaceutical manufacturers are rapidly evolving from experimenting with GenAI to transforming operations. In a recent BCG survey, approximately 25% of biopharma companies and some 10% of medtech companies reported that AI accounted for cost reductions and revenue increases of at least 5%, along with significant improvements in speed and agility.

But a significant portion of health care manufacturers remain cautious, with around 60% of biopharma and medtech companies reporting that they have no plans for GenAI or, at best, are taking a wait-and-see approach. This is an enormous missed opportunity.

Stay ahead with BCG insights on the health care industry

Health care manufacturers that have started to deploy GenAI in a wide range of use cases, from supply chain to manufacturing to quality management, have the potential to deliver more value in 2025 than they have seen in the last three years combined. But before health care organizations can capitalize on GenAI’s potential, they must first understand its capabilities, its limitations, and where it can create the most impact.

High-Impact Use Cases for GenAI in Health Care Operations

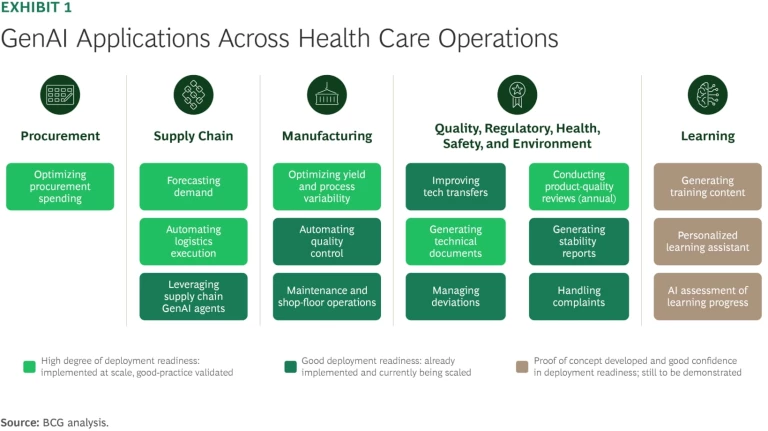

BCG has identified dozens of GenAI use cases across key health care operations, prioritizing those with the greatest potential to deliver significant value. (See Exhibit 1.)

To identify the right GenAI opportunities, use cases can be categorized into three broad value plays:

- Deploy: Leverage configurable, off-the-shelf GenAI tools in everyday tasks to improve enterprise productivity. These solutions are already on the market and can be customized to meet the needs of health care companies.

- Reshape: Reimagine critical functions end-to-end with GenAI to drive major gains in efficiency and effectiveness.

- Invent: Create new experiences, offerings, and business models powered by GenAI.

While all three plays can be initiated simultaneously, each comes with its own productivity outcomes, cost–benefit tradeoffs, requirements for success, and implications for operating models. Using the Deploy, Reshape, Invent framework, we have prioritized three ways GenAI can be used in health care operations to boost performance and transform core functions.

Deploy GenAI agents to assist on the shop floor. AI agents can offer real-time troubleshooting guidance based on documented best practices and standard operating procedures, and they can reduce downtime by suggesting solutions for common equipment or process issues. By integrating GenAI with process data, AI agents can help operators understand anomalies, monitor key performance indicators, and recommend actions to optimize process conditions. This will maximize equipment availability, uptime, throughput, and overall equipment effectiveness—delivering bottom-line value to operations.

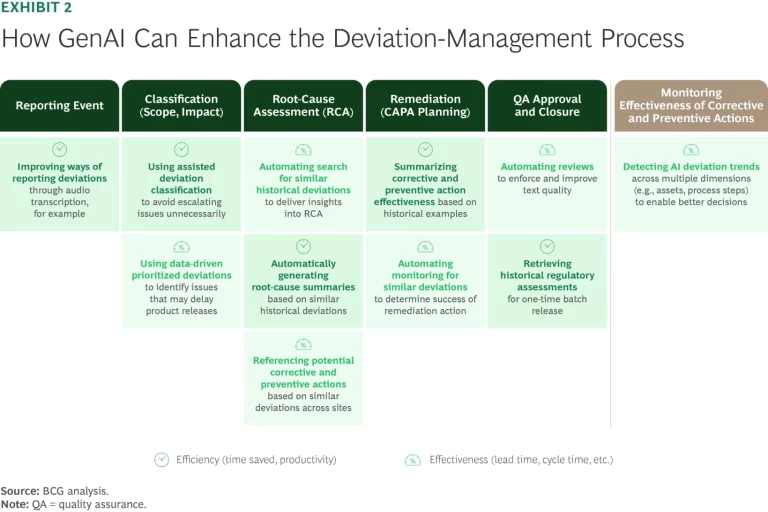

Reshape regulatory affairs and quality reporting. Early adopters in health care are using generative AI to innovate, automate, harmonize, and simplify elements of their quality management systems and regulatory affairs functions, gaining a significant competitive advantage. By automating regulatory and quality reporting, aiding in risk management, and supporting continuous compliance monitoring, GenAI can help pharmaceutical and medtech companies achieve higher standards of quality and regulatory compliance, ultimately improving patient safety and product quality.

With GenAI-assisted deviation handling, for example, companies can transform the entire deviation investigation and management process. GenAI can clarify trends, classify deviations by severity, identify root causes, and recommend appropriate corrective actions. (See Exhibit 2.) These enhancements will streamline otherwise manual and time-consuming processes, enabling dramatic gains in efficiency, productivity, and accuracy.

Reinvent tech transfer with GenAI. A GenAI agent can automate the initial end-to-end planning phase and provide intelligent execution support for tech transfers—allowing project teams to eliminate a large number of operational tasks, achieve best-in-class tech transfer times, and reduce the large variability typically observed between transfers. The GenAI agent could even provide this support for a complex portfolio of tech transfers with various interdependencies.

By integrating data from current and past tech transfers, an AI agent can analyze various scenarios, automatically generate timelines, identify potential risks based on previous lessons learned, automate reporting and tracking, and provide advanced analytics for critical actions (such as predicting how production volumes will shift from one site, process, or technology to another over time).

Key Enablers for Ops Leaders

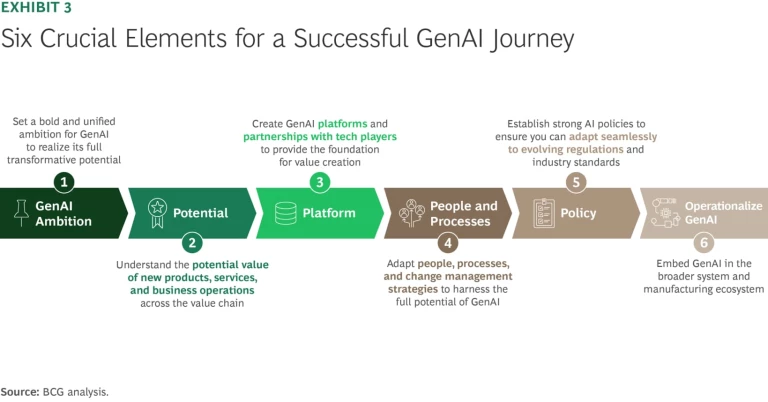

Simply setting up the right infrastructure and deploying GenAI tools is not enough to fully unlock the potential of GenAI in health care operations. Health care manufacturers must be prepared to make changes in people strategy, processes, and technology to fully capitalize on GenAI's capabilities. Although each manufacturer will face its own set of unique challenges, we have identified six key enablers for achieving successful GenAI transformations at scale. (See Exhibit 3.)

Set a GenAI ambition. Manufacturers must have a clear vision of where generative AI can offer the most significant competitive advantage within their manufacturing networks and value chain. As a first step, organizations should assess the potential impact of GenAI on current operating models and value chains, identifying areas for improvement. It is important to recognize that both value chain activities and operating models could shift significantly, so companies should strategically focus on where they can achieve the greatest impact.

Understand where GenAI can create value. Use cases should be prioritized based on the tangible impact they can deliver, the effort and cost required for implementation, and how quickly they can scale. Using the Deploy, Reshape, and Invent plays, companies should start with proof-of-concept pilots that allow solutions to be tested, refined, and validated before scaling.

A key success factor is the availability and quality of data, which forms the foundation for any analytics or modeling efforts. It’s especially important to identify and address gaps in data availability or quality and anticipate how these issues might hinder the successful piloting and scaling of use cases. As part of this process, GenAI can be implemented to assess data quality.

Leverage GenAI platforms and partnerships. When setting up a GenAI platform, organizations must carefully decide whether to build it internally, buy existing solutions, or partner with external providers.

The criteria for choosing the right partners will differ. For platform partners, key considerations include geographic coverage, portability, security, and privacy. When selecting a GenAI model, important factors include model size, fine-tuning capabilities, and compatibility with the chosen platform. Each decision plays a critical role in shaping the platform’s performance, flexibility, and compliance.

For common operational needs (that is, the Deploy play), off-the-shelf solutions offer a cost-effective way to achieve early success. However, as manufacturers pursue more industry- and company-specific requirements (the Reshape and Invent plays), in-house customization and build options may be required for more specific applications.

Align people, processes, and change management. Choosing the right models, platforms, and partners is just one part of successfully deploying GenAI tools. It’s even more important to build a team with the right skills to develop, launch, scale, and maintain GenAI use cases before the project begins.

To achieve lasting, large-scale impact with GenAI, companies must build an agile, data-driven culture. This starts with helping employees understand how GenAI can be applied effectively on the shop floor and across sites and networks. Everyone involved needs to see the real-world benefits, like faster regulatory approvals, fewer unplanned outages, and reduced overtime through smarter supply chain planning. Leaders play a critical role in building support. They must clearly communicate how GenAI fits into the company’s future, especially to frontline teams, to generate buy-in across all levels.

To enable this shift, many organizations will need to adjust their business processes, structures and operating models, clarify roles and decision-making authority, redesign job profiles, and update talent strategies to develop skills in areas like prompt engineering and machine learning. These steps are essential to ensuring teams can effectively operate GenAI tools and scale more advanced use cases.

Establish responsible AI policies to manage risk. Despite its immense potential, generative AI also presents certain risks associated with biased data, intellectual property rights, incorrect outputs, and cybersecurity vulnerabilities. To mitigate these risks, health care companies need a responsible GenAI framework that spans the entire organization, covering strategy, governance, processes, technology, tools, and culture.

Functional GenAI use cases, such as those that assist in managing internal, regulated workflows with human oversight (and do not directly impact the product itself), offer a safe way to uncover pitfalls, identify tradeoffs, and manage risks early in the process. This approach allows organizations to refine their GenAI strategies and mitigate potential risks while scaling up their operations.

Operationalize GenAI. GenAI alone will not drive the majority of value across the operations value chain. Traditional AI models, such as machine learning, will continue to play a key role—particularly in manufacturing, where structured data from systems like manufacturing execution systems can be effectively analyzed using more conventional data analytics and machine-learning techniques. To fully unlock GenAI’s potential at scale, companies must also invest in lean production systems, adopt agile ways of working, and integrate Industry 4.0 technologies.

GenAI in health care operations has moved beyond the experimental stage, and some leading manufacturers are already gaining a lasting competitive advantage. Their operations are faster, more cost-effective, more agile, and they have better quality control and compliance across their supply chain and manufacturing.

With an estimated compound annual growth rate of 85% and a market value of $22 billion by 2027, GenAI in health care is poised to transform the industry. By integrating GenAI into health care manufacturing, companies can create safer, more efficient, and cost-effective production workflows, ultimately benefiting manufacturers and patients alike.