Even as operational leaders around the world face pressure to improve productivity, the most effective solution is already on the payroll: frontline employees. BCG research shows a clear correlation between frontline engagement and operational performance. To unlock this potential, companies need to increase engagement on the frontlines by changing how roles are empowered and led. In our experience, companies that take four steps to enable the frontline see these measurable improvements:

• A sustainable increase of 5% to 10% in profits

• Gains of 5% to 10% in employee engagement

• A two-fold increase in time on task

• Improved equipment reliability and safer operations

Growing Challenges for Manufacturers

COOs at manufacturers face a range of challenges. Raw-material and labor costs are rising with inflation, supply chains remain volatile, and global competition is pushing efficiency benchmarks ever higher. At the same time, aging assets demand more care, and a wave of retirements is draining valuable experience from the frontline workforce. As a result, companies can see rising downtime rates for equipment and declining maintenance productivity. Without intervention, these issues erode performance, safety, and competitiveness.

Frontline employees and their direct managers are uniquely positioned to help meet these challenges, but they are often bogged down in processes and tasks that consume precious time and deliver little value. Managers often spend their days juggling conflicting priorities: hours taken up by meetings, administrative reporting, and firefighting. This means less time in the field, where they can coach teams, reinforce standards, and spot emerging risks. The outcome is predictable: disengagement, inefficiencies, and an environment in which small issues grow into costly problems.

Four Steps to Enable the Frontline

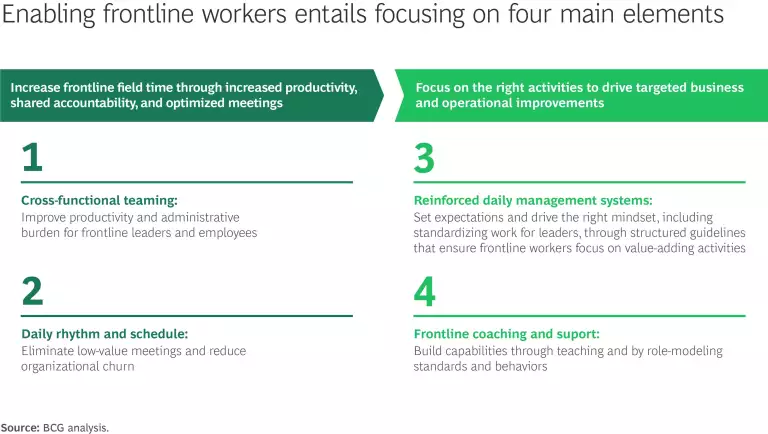

Our work with leading manufacturers points to four measures that companies can take to improve engagement and dramatically increase productivity. (See the exhibit.) The first two measures improve frontline field time; the other two get frontline employees focused on the right tasks.

- Cross-Functional Teaming. First, teams need to coordinate directly across functional lines. Cross-functional teaming brings together people from operations, maintenance, procurement, and other roles to collaborate directly and head off problems before they arise. For example, a rotating equipment engineer walking the unit with operators during rounds can identify small anomalies in machinery and address them before they escalate, ensuring faster, cheaper fixes and less downtime.

- Daily Rhythm and Schedule. Many frontline leaders spend more time handling admin than they spend in the field, or they repeatedly get pulled away by crises. Instead, factories need to establish a daily rhythm—streamlined, tiered, structured meetings that escalate issues quickly. These meetings happen on the floor, with a specific cadence. A tier 1 huddle might flag a reliability concern, which is resolved in a tier 2 meeting with maintenance and operations during that same shift. In this way, problems are addressed in real time, not deferred for days, and organizations free up hours for value-adding work.

- Reinforced Daily Management Systems. Consistency in operations depends on strong routines: clear operator rounds, disciplined maintenance planning, and real-time monitoring. A robust management system ensures that emerging risks are flagged early and addressed systematically. Standardized processes provide frontline supervisors with structured guidance on how to run effective meetings, establish a field presence, and focus on what matters most.

- Frontline Coaching and Support. Systems alone cannot change culture. A new poster from HQ in the coffee room is insufficient to support change. Direct employee coaching is required to ensure that new behaviors take root. That means role-specific support—such as guiding team leads to strengthen accountability during shift handovers. Leaders who engage regularly in the field and on the factory floor—not just to audit but to listen, support, mentor, and share lessons learned—build trust and model the behaviors they want to see.

Stay ahead with BCG insights on cost management

Putting the Ideas into Action

Frontline leaders who have taken this approach offer consistently positive feedback. A leading energy company applied these ideas in a pilot program at its two refineries. Within four months, time spent on productive field and engineering activities increased by a third, employee engagement rose 6 percentage points, and seven of nine key operating metrics improved.

The path forward is clear: manufacturers must redesign frontline roles, invest in leadership coaching, and streamline daily systems. By doing so, they not only double productivity but also create an engaged, empowered workforce that sees its contribution recognized and valued. In an industry where performance pressures are only set to increase, frontline enablement represents a powerful and practical lever for transformation. The companies that embrace it will be the ones best equipped to navigate uncertainty and build lasting advantage.