In recent years, global manufacturers have faced an array of challenges, from slow economic growth to an uncertain regulatory landscape and rising electricity prices. To compete effectively in a rapidly changing global marketplace, these companies must operate with greater efficiency and flexibility than they have in the past, responding quickly to changing market dynamics and grasping emerging opportunities. As part of this effort, they need to examine the costs and effectiveness of their maintenance and repair programs.

Across industries, maintenance is typically considered a service organization, rather than an integrated part of production. There are significant inconsistencies between a maintenance system’s goals and how people, processes, and tools are organized. Work process standards, for example, are often lower than production standards, and even when a company adopts more advanced processes, such as autonomous maintenance, these may not significantly improve operating efficiency.

To reduce downtime and extend the lifetime of equipment, manufacturing companies must make their maintenance function proactive instead of reactive. This, in turn, will reduce their annual expenses and parts inventories without compromising safety or quality.

BCG recently helped a major international cement company design and implement an ambitious maintenance excellence program to keep equipment performing at peak efficiency. Based on that experience, we have identified four key principles that other companies can use to design their own maintenance system, as well as a three-level process to ensure that a uniform system gets adopted throughout the organization.

The Four Principles of World-Class Maintenance

To design a world-class maintenance system, any manufacturing company, regardless of size or geographic reach, should follow the following four principles:

- Empower employees. The maintenance system’s success depends on improving skills and involving employees in the development of new work standards. Empowering employees is the foundation for the other three principles. It includes training in standard maintenance as well as in lean methodologies to increase a sense of equipment ownership.

- Minimize costs. Focus on a clear increase in maintenance efficiency, reflected in annual cost reductions and reduced spare-parts inventories.

- Increase asset availability. Meeting growing customer demand requires continuous improvements in asset utilization and equipment effectiveness. Shifting from a reactive to a proactive approach can reduce breakdowns and extend the lifespan of equipment.

- Emphasize safety and quality. In addition to efficiency, priorities should include safety, environmental impact, and product quality.

Designing the System

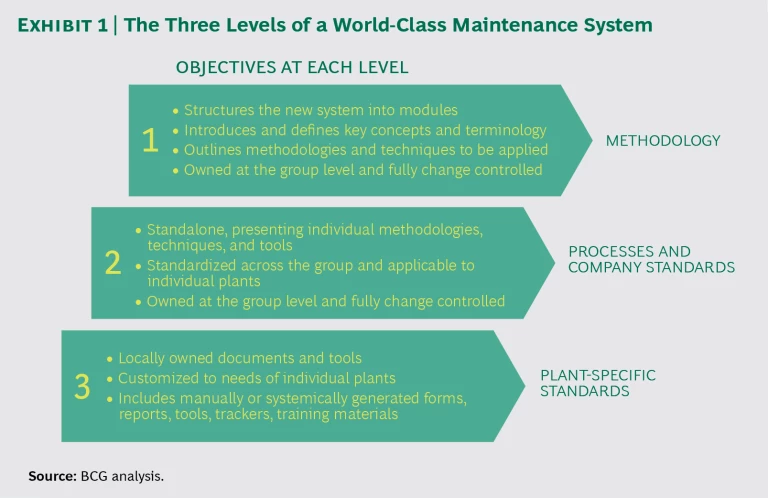

A uniform maintenance system allows for consistent implementation across all plants and operations and ensures that the best practices developed in one plant are shared with others. In our work with the global cement maker, BCG developed a platform for continuous improvement by combining the company’s own internal practices with lessons from other industries. The system is built on three levels. (See Exhibit 1.)

- Methodology. This comprises the core structure of the maintenance system—inspection, planning, and execution—as well as explanations of why the changes are being made and descriptions of the system’s key concepts and terminology, techniques, and strategic objectives.

- Processes and Company Standards. These are the individual methods, techniques, and tools, such as work order documents, that plant maintenance teams will adopt. They are standardized across the company and apply to each individual plant.

- Plant-Specific Standards. These are the tools and processes that are customized to the needs of individual locations. They include manually and automatically generated forms, reports, tools, trackers, and training materials.

Using this platform, the cement company collected existing maintenance procedures from each of its plants, reviewed them, and standardized them across all operations. This made the system easily adaptable to changes proposed by individual plants, because receiving recommendations, developing solutions, and implementing changes all proceeded according to a shared and uniform process. The standardized procedures conform to the logic of the maintenance process:

- Inspection: monitoring and measurement of conditions, analysis of trends, and identification of maintenance needs. Identifying the appropriate maintenance strategy is critical. With the trend toward automation and data exchange in manufacturing (known as Industry 4.0), more maintenance is condition based; that is, it is done according to whether equipment shows signs of declining performance or possible failure.

- Planning: defining methodology, manpower, safety procedures, spare-parts needs, associated costs, and other resources that are essential for efficient and safe maintenance. Companies should identify standard times for all work orders and work to improve the schedule systematically.

- Scheduling: defining the work program based on operational priorities, manpower, resources (both internal and external), and equipment availability. Scheduling is typically performed by an IT-supported maintenance system. However, for initiatives such as autonomous maintenance, which gives operators more responsibility for preventive maintenance, planning on the shop floor may be more effective.

- Execution: completing maintenance jobs to the highest level of safety and effectiveness while maximizing equipment availability and efficiency. Efficient maintenance can be supported by standard operation procedures. Currently, new technologies such as augmented reality are changing the standards for executing maintenance work orders.

- Continuous Improvement: upgrading practices to enhance performance in response to ideas from multiple sources (such as plant employees and the corporate engineering department). All maintenance and production employees should be engaged in this process.

- Management: setting goals and objectives, organizing and managing resources, and monitoring the performance of each maintenance function through KPIs and supervision. Most effective performance management is based on visual management tools.

The maintenance organization, led by the maintenance manager, is divided into two key areas: one focused on the execution of maintenance tasks and the other on the management of resources and backlog—or on the work that needs to be done.

Three Phases of Implementation

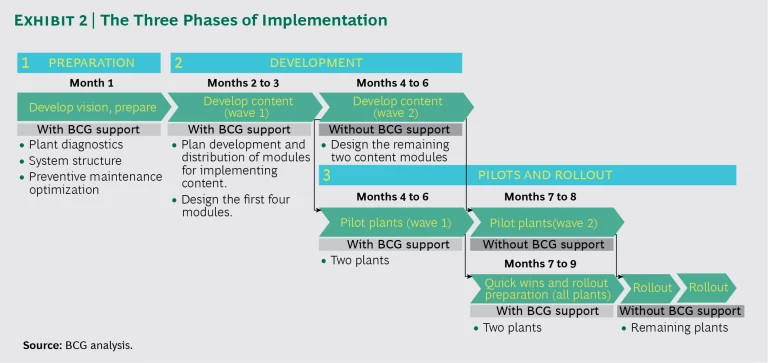

Once the company has designed its maintenance system, it should designate a project team to run the implementation and monitor and support cultural shifts across plant teams. For the implementation to be successful, maintenance leaders must take time at the beginning to explain the concept of the new system to the project team and its role throughout the three main phases of implementation. (See Exhibit 2.)

Preparation. Well-defined preparation, including setup and governance, is key to an efficient maintenance transformation. We recommend that companies establish a steering committee responsible for releasing technical specifications for maintenance procedures, making strategic decisions, and taking the initiative required to promote change at the plant level. The global cement company’s steering committee consisted of a project manager and many experienced maintenance engineers from different locations who disseminated maintenance standards to all the plants.

Maintaining consistent project management governance requires strict monitoring to ensure a rapid response to potential roadblocks. Members of the steering committee and the project and plant management teams should have regular meetings and produce reports on a weekly and monthly basis.

In addition to setup and governance, the preparation process should include creation of work teams by function and plant; development of a roadmap with timeline and milestones; development of top-down objectives and targets; development of a program scorecard with KPIs; development of a communications plan; analysis of maintenance information from representative plants; and alignment on the overall concept and structure of the maintenance program.

Development. For a new maintenance system to succeed, employees must accept it, which requires that they have input. Companies should therefore create a development team, composed of a significant number of maintenance workers who can contribute their hands-on expertise. The team may also consider other companies’ practices, input from maintenance experts, and external benchmarks. The development team works within the framework established by the steering committee to create manuals, adopt policies and key practices, and define maintenance requirements, resources, capabilities, and costs. This process should take about three months from the time the preparation phase is completed.

The development team should also consider creating a set of tools, such as templates for inspection practices and techniques, to support the implementation of the new system. The tools can be adopted gradually and adjusted based on feedback from maintenance teams on the plant floor.

In addition, companies should consider technological changes that can improve efficiency. For example, the global cement company adopted an automated reporting system to measure the maintenance backlog. This is critical because backlog is a reference point for all plant functions. The company also developed equipment specification coding, which allowed for better equipment tracking, document management, and technical and financial analysis.

Finally, the cement company adopted the highest global standards for risk-based autonomous and predictive maintenance, as well as Industry 4.0 innovations such as augmented reality (AR). Now still in their infancy, AR systems will eventually help maintenance workers select the proper spare parts and send real-time repair directions to their mobile devices. For example, a worker wearing AR glasses could receive instructions for replacing a particular part while actually looking at the system in need of repair.

Pilots and Rollout. Pilot plants allow the company to test maintenance systems, assess any necessary changes, and make adjustments. These plants should be designated by the development team, and all pilot site operations should follow a standardized process:

- Compare the plant’s new and existing maintenance systems using gap analysis. This must include management engagement and a thorough discussion of plant resources and the new system’s effect on existing procedures.

- Establish the required database through local and centralized maintenance resources.

- Launch first-priority activities with progress measured by KPIs and the status reviewed by the central team.

- Implement second-priority activities through the plant team, with remote support by the central team and tracking by monthly audits.

The development team should conduct meetings with pilot plant managers prior to the launch to assess the plant’s status, develop transparency about the changes, and share overall objectives. This will result in broader acceptance and support from plant workers.

At the cement company, pilot plants reported sustainable maintenance cost reductions of 5% to 8%, and their reliability increased by 2 percentage points in the first year. Their mean time between failures rose by 6.7% compared with the previous year, and the company saw a significant increase in its completion rate while reducing its administrative workload. For example, work orders in the pilot plants fell by about 65% on a weekly basis. Standardization has improved, responsibilities of the inspection team and other departments are more clearly defined, and collaboration between plants has increased.

While results will vary depending on the business and the nature of its maintenance operations, companies that wish to improve their maintenance systems should look beyond basic operational processes. World-class maintenance begins with a vision and a clear link to the business, incorporating best practices in operations and clear governance to define performance. Maintenance workers must have input into the system’s development to ensure their support. With the proper design, preparation, and implementation, companies can increase the efficiency and cost-effectiveness of their global maintenance system.