Globalization is leading more companies to adopt decentralized organization models—and for good reason. Decentralization offers clear advantages, such as a higher degree of entrepreneurship, increased local adaptation of products, better market intelligence, and faster response times to changes in local demand. However, this model also imposes challenges on manufacturing organizations. In our work with decentralized companies, The Boston Consulting Group has found that many of them show highly variable performance across sites, and limited—or inconsistent—sharing of best practices. As a result, their aggregate performance is mediocre at best.

These organizations need to change. The global competitive environment, which is more cutthroat than ever before, is increasingly complex and competitive, and many of the easy gains have already been captured. Decentralized companies need to implement change that matters, including advanced manufacturing approaches such as lean. As a prerequisite, these companies must learn to apply greater discipline and standardization, as well as mechanisms for continuous improvement.

Through our client work, we have identified three areas that require additional emphasis to implement operational changes—such as lean—in a decentralized organization: the level of standardization, frontline leadership, and change processes. All require a foundation of rigor if they are to succeed. In addition, several enablers can ensure success: performance governance, a continuous improvement process, an organization structure, and capability building. In the aggregate, these elements come together to form an overall production system that can consistently deliver better performance across manufacturing sites.

The Level of Standardization

Taiichi Ohno, father of the Toyota Production System, famously stated, “Where there is no standard, there can be no kaizen.” In other words, forget about improvements if you haven’t defined a baseline with standards. Standardized work is a critical element of high-performing, consistent, and predictable operations. World-class companies famous for operational excellence—for example, Toyota and Procter & Gamble—discovered this decades ago. (See “Two Exemplars of Operational Excellence.”)

TWO EXEMPLARS OF OPERATIONAL EXCELLENCE

Toyota and Procter & Gamble, both global companies, have attained their world-class status by developing a highly standardized and rigorously consistent way of working across their facilities worldwide.

Toyota

Toyota has standardized its approach to shop floor management and continuous improvement. Each plant rigorously standardizes each step of the manufacturing process and synchronizes it with the overall operation’s takt time, which links the production schedule to customer demand. Team leaders and supervisors monitor adherence to standards—training operators and filling in when required—while conducting reviews and continuously refining the standards. Line operators are empowered to stop production lines at the first sign of error so that they can immediately resolve problems—with the assistance of supervisors—and resume production. This approach doesn’t depend on any one worker, supervisor, or facility: it’s the way the entire production system works. Notably, however, the system doesn’t force standardization across lines or sites. Instead, because the goal is for individual facilities to experience the learning process, the system leaves room for line operators to suggest improvements and develop best practices. Some innovations are applied only locally, while the best technical practices are shared globally.

Procter & Gamble

Like Toyota, P&G is known for its rigorous production system. The company has defined “hard” and “soft” points for implementation at its plants. Hard points are mandatory and may not be compromised, while soft points function as guidelines that may vary from plant to plant. For example, daily shop-floor meetings drive the manufacturing rhythm and continuous improvement (a hard point) with a few standard KPIs (also hard), but whether a meeting is conducted on a white board or with electronic displays is a soft point.

Yet, on the basis of our experience, we know that these companies are exceptions, particularly among decentralized organizations. More commonly, we find phenomenal successes at company sites that are isolated events: the success doesn’t spread to the company’s other sites and generate benefits at scale. For example, one of our clients, a leading operator of dozens of ports worldwide, had been appearing routinely in the top rankings of global benchmarks, with one or two of its ports boasting the highest productivity measurements in the world. However, the productivity of other ports in the company’s portfolio trailed by 40 to 60 percent. The differences could not all be explained by technology—most ports had very similar equipment—or by labor union constraints in some markets (another popular explanation). Rather, we found that operational and leadership practices varied considerably across ports and were, by far, the most significant drivers of performance.

Lack of standard operating practices affects R&D processes as well. Working with another BCG client, a large industrial company that manufactures refrigeration equipment, we found that R&D project managers were using a variety of financial models to estimate the expected financial benefit of their projects. They even used different prices for copper, a critical raw material in the company’s products. The result was that executives could not make an objective assessment of the most promising products for their R&D pipeline. Even though each of the products had a standard business plan consisting of market analyses, cost estimates, and financial-impact development, the lack of standardization in the front-end product-development templates and processes meant that executive teams were comparing apples with bananas.

The problem is that individual managers tend to resist standardization—often vehemently, and sometimes for valid reasons. Some well-intended standards that result in additional cumbersome work and bureaucracy don’t actually improve operations. Standards can also hinder entrepreneurship, innovation, and local adaptation. In many cases, however, the problem is simply pride, “superiority bias” (managers thinking that they are better than they really are), or the not-invented-here syndrome (in which ideas from elsewhere trigger immediate skepticism). Thus, where managerial autonomy is high, the default is to resist anything emanating from the center. One manager with whom we talked at a decentralized company compared launching a global improvement program with running headfirst into a moving train. “Somebody’s going to get hurt,” he said.

How should decentralized organizations start to implement standards? First, they should realize that the true objective is not to standardize hundreds of processes. Instead, they must be selective, choosing a critical few processes that are in great need of improvement—and standardization. This is especially important at the beginning of the process, when organizations need to show quick wins.

One of our clients, a cable manufacturer, realized that its plants had three specific sources of reduced equipment efficiency: product changeover times, line start-ups, and missing materials. The company had written standards and descriptions that were meant to contain the problems, but each was being performed differently by different operators. Product changeover times varied by as much as 70 percent. Moreover, two critical bottlenecks at every plant (each with 15 to 20 lines) determined overall performance. By rethinking and standardizing best practices for each critical process—and applying the new standards rigorously, especially at the two bottlenecks—the company was able to improve equipment efficiency by more than 40 percent in a short time.

Similarly, the refrigeration company mentioned above, with its varying templates and processes for R&D, began by addressing a few critical steps in its ideation process. For example, it introduced a standardized one-page form for evaluating a new idea and a four-page form for assessing the business case for a project. R&D teams now follow process steps rigorously, allowing management to evaluate business plans with confidence. As a result, innovation rates have improved.

Standards can also apply to nontechnical aspects of the company. For example, one of our clients in the chemical industry embarked on a major improvement initiative. Early on, the management team faced the task of defining critical points that needed to be standardized across the company. As they realized the degree to which plant management and setups varied, the executives opted to standardize roles and responsibilities across plants rather than processes. They also developed a more transparent qualification system for senior operational staff. As a result, plants started running in a more harmonized way.

Over time, companies can build on their early progress and standardize other aspects of production. However, the ultimate goal is not to standardize everything. The right number of processes—and the right balance of standardization and site autonomy—varies by industry and organization. In all cases, local sites should have some flexibility to think creatively and innovate.

In essence, the standards described here are the components of a production system: a set of values, principles, and methods that are standardized and applied as a way of working across the entire organization. The challenge in decentralized organizations is that the culture of standardization and discipline must exist everywhere—in sites and facilities around the world. Achieving this requires clear direction from top management, extensive training, and enhanced control, which can be a big shock to decentralized organizations. More specifically, it requires significantly different roles for leaders at all levels of the company.

Active Frontline Leadership

It is all too easy to establish standards. It is far more difficult to enforce those standards and make sure that they stick. Sustainable standards require leaders, particularly frontline leaders—the on-site managers and supervisors who directly oversee how the work gets done. In our experience, a lack of frontline-leadership support is the main reason why improvements do not last. This may suggest that success is solely a frontline-management issue. It’s not. Frontline leaders need support and reinforcement from their direct managers, and those managers in turn need to be held accountable—all the way to the senior leadership of the company.

Consider, for example, a pharmaceutical company we’ve worked with. In evaluating one of its European plants, we quickly found that product changeover times were too long and were a principal factor in the site’s low equipment-efficiency rates. Looking at historical data, we noticed that for a brief period in the past, changeover times had been up to three times faster. The operators recounted how they had successfully implemented a new changeover procedure, which allowed for doing more work in parallel. This required greater effort and a high degree of coordination among the plant’s employees (and frontline leaders). However, when frontline leaders stopped supporting the initiative—essentially, when the senior leaders stopped insisting on it—the changeover times reverted to historical levels. The company has since worked extensively with its leadership teams at the corporate and plant levels to reestablish standards and secure a strong leadership commitment to improvements. And performance has improved significantly.

As this example shows, enforcing standards requires rigorous, consistent, and sustained effort over time. Once a company establishes a set of standards, its leaders need to hold teams accountable for working according to those standards and for improving them over the long term. In turn, this requires that managers conduct “leadership walks” and make their presence known. Leadership walks are not new, but they are, in many cases, not focused and can therefore be very superficial.

In our experience, we have found that leaders in successful lean companies spend significantly more time on the front line than do leaders in companies that are not lean, and they play a critical—and daily—role in problem solving and continuous improvement. Their role in continuous improvement is not that of an expert. Instead, they are expected to apply a business perspective to improvement, asking questions and providing guidance on what adds value for the customer.

Accordingly, leaders must walk the line daily, conducting very specific tasks related to the selected standards: they observe, enforce, assist, coach, and help their frontline teams, and they solve problems at the lowest level possible. They must also model the desired behaviors, such as cooperative behavior among departments and adherence to the established standards.

Doing this can require a sizable investment of time early on, but once the improvements begin to gain traction, the time is recouped. For example, another pharmaceutical company analyzed the calendars of production managers to understand how they spent a typical workweek. The analysis revealed that the managers spent most of their time in meetings, often addressing ongoing problems or discussing shop floor issues. Changing such a culture was not easy. It required a top-management mandate that forbade meetings during the morning hours. Once that time was freed up, managers were able to spend more time on the shop floor, and they became more aware of developing issues, making meetings redundant. An increased focus on solving problems at their root cause—and as early as possible—eliminated many of the daily crises, ultimately saving significant time while improving plant performance.

Not all frontline managers willingly embrace such changes. In many decentralized organizations, units are run as separate fiefdoms whose heads define their respective cultures. In order to implement a culture of standardization, all unit heads must be aligned with the new way of working. For this reason, most successful large-scale transformations require changes in unit leadership. Our experience is that 10 to 40 percent of unit heads need to be replaced with new leaders who are ready, willing, and able to change.

It is worth noting that frontline managers may lose some of the autonomy they once held, but they will likely gain new roles and responsibilities. In our experience with automotive OEMs and other world-class production companies, the most effective daily shop-floor-management operations and the strongest continuous improvement processes are run by those with the most empowered frontline managers. Similarly, standardizing roles and responsibilities has additional network benefits: peers with the same roles can connect and form communities, allowing them to exchange ideas and best practices from similar perspectives.

Furthermore, companies need to spread the responsibility for lean as widely as possible, throughout the line organization. We sometimes encounter a lean manager who is responsible for lean in a plant or company. This arrangement is dangerous because it pulls ownership of lean away from the line and concentrates it in a sin-gle individual. Lean managers and other change agents should be strong and well-respected leaders, and they should take ownership of lean tools and methods. However, they should not take ownership of the overall implementation. Companies also may use special teams or internal or external consultants to implement lean programs. Although this is a good approach to start, accelerate, or reinvigorate a lean program, ownership and overall responsibility need to return to the line organization quickly if the program is to be sustainable. There is one caveat for decentralized organizations: plants should not have the latitude to “do” lean in their own way: this risks the development of dependency on particular people and the mediocre results we’ve discussed above. Instead, companies need to design and standardize a lean production system—with soft and hard points—before the individual plants embark on their respective journeys.

Rigorous Change Processes

In addition to standards and frontline leadership, implementation of lean or deployment of a production system in a decentralized company requires a new level of transparency and accountability. This entails change not only at the unit level but also at the company level, where reporting, follow-up, and support mechanisms are executed. Such change is complex, and it’s where we have seen companies fail.

While there are many approaches to governance of large decentralized programs, three best practices are worth highlighting:

- Effective governance through an activist program management office (PMO) that empowers the line rather than usurping control

- An explicit focus on milestones, operational and economic impact, and the likelihood of success

- Formal rigor testing to ensure reliable reporting on the status of change efforts

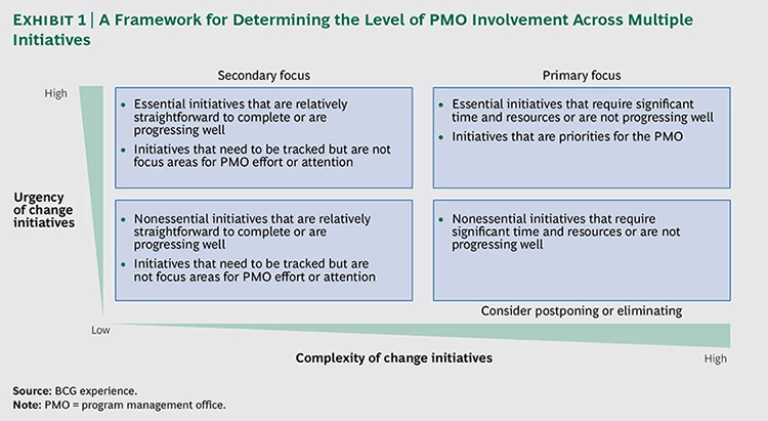

Effective governance is critical. Senior leaders must recognize that in a decentralized company, the various unit heads need different incentives. Unit heads, particularly low-performing ones, may have little reason to change the status quo they have created. Greater rigor and transparency are required to break this deadlock; the company must reward ambition and not tolerate sandbagging. Many companies rely on a PMO to follow up on progress and hold unit heads accountable. PMOs must take an activist role, leading the change but empowering rather than usurping the line. (See Strategic Initiative Management: The PMO Imperative, BCG report, November 2013.) Even if the company does not establish a formal PMO, it needs to ensure that the capability and appropriate support tools are in place to support more complex change initiatives and to track the delivery of benefits. (Exhibit 1 shows a framework for determining the right level of PMO involvement among multiple initiatives.)

A crucial first step is determining the long-term potential in a site. That determination allows for a constructive discussion with site management about the time line for implementation, as well as any required resources and prerequisites. For example, after a comprehensive diagnostic of the potential for improvement at each site, the port company discussed above developed—with the clear commitment and ownership of each site’s management—implementation roadmaps with critical operational metrics linked to financial outcomes. These were then “frozen” and uploaded to an online tool through which the PMO reported exceptions to the roadmaps as the project unfolded. (This kind of minimally sufficient reporting can eliminate unnecessary communication and avoid overloading executives with information that they don’t need.) At first, the units did not appreciate the greater transparency, but in time, the increased rigor helped them stay the course and achieve the objectives outlined in the plan. In general, setbacks in local implementation stemmed from the failure to strictly enforce standards. Through implementation reporting, such issues became “flashing red lights,” and the unit was able to make course corrections early.

Milestones and objectives break the initiative into smaller steps. The building blocks of any initiative come together as a roadmap—or roadmaps—that consists of (typically, 15 to 25) very specific milestones that tell the story of the initiative. Roadmaps lay out time frames, financial and operational metrics, lead indicators, interdependencies, and accountabilities. Their fundamental purpose is to help executives understand how the effort is proceeding and where things might be going wrong, providing greater transparency and allowing for necessary course corrections. (See Changing Change Management: A Blueprint That Takes Hold, BCG report, December 2012.)

Rigor testing ensures that roadmaps are meaningful. Many companies put roadmaps into place at the beginning of a change initiative, but the roadmaps themselves can fall prey to garbage-in, garbage-out reporting. Rigor testing is a formal process that ensures that the roadmaps accurately reflect how the initiative is actually proceeding. In this process, roadmap owners, sponsors, and the PMO, finance, and HR representatives assess each roadmap to ensure that it is clear enough to be readily implemented, that the benefits and timing are clearly and correctly identified, and that the critical risks, interdependencies, and issues are sufficiently explicit and tested. Rigor testing helps companies capture far greater value than they otherwise could.

Implementing these aspects of change requires observance of important principles. First, companies should avoid creating any unnecessary complexity. The aim is not to set up a major bureaucracy but to ensure thorough and thoughtful planning and clear commitment and transparency. In addition, companies must always treat their employees with respect. It is critical that workforce members remain engaged. Last, companies must build the basis for future change by training and developing their people.

Four Enablers

Companies cannot develop standardization, leadership, and centralized change processes in isolation. Four enabling processes can help create an enhanced—almost cultlike—commitment to the level of rigor that is required to drive successful change in decentralized organizations. The four key enablers are performance governance, a continuous improvement process, organization structure, and capability building.

Performance Governance. A rigorous performance-management and governance system ensures that the company tracks both financial and operational performance at a comprehensive and detailed level. For example, in a typical monthly operational review, a site manager might report on developments related to finance, safety, quality, and cost and delivery. However, many of these are backward-looking indicators.

By contrast, a company with rigorous performance management will consider forward-looking and operational drivers of performance such as changeover times, shift change times, and the amount of scrap on specific machines—while spurring the site to push its limits.

Rigorous performance management must also be conducted frequently—daily, hourly, or even in real time, at the shop floor level—in order for managers to be able to react to deviations. As mentioned above, this is where the role of frontline leaders is critical. Visual management tools such as performance boards and displays help people recognize deviations, allowing for fast corrective action and triggering continuous improvement efforts to prevent future occurrences.

Continuous Improvement Process. A strong continuous improvement process—and the culture that supports it—makes the change effort take root. The process needs to ensure that improvements are codified as standards and that there is a mechanism for enforcing and improving those standards.

Continuous improvement requires two distinct mechanisms. The first is a trigger system that traps deviations in performance (such as a machine breakdown that disrupts daily production) and initiates corresponding actions that prevent their recurrence according to a rigorous and systematic problem-solving methodology. These mechanisms should be part of the daily routine and cycle. The second mechanism is ideation, through which the company identifies improvement opportunities, codifies them, and prioritizes them for implementation.

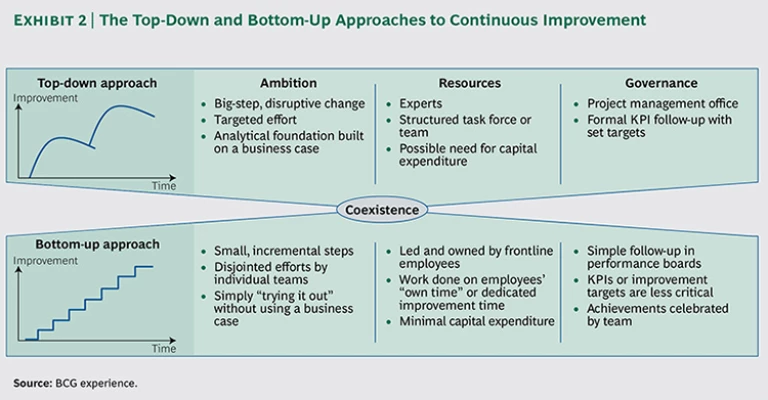

Ideation can take several forms. The top-down methodology uses expert knowledge to find major improvements and step changes in performance. This is beneficial for ensuring an end-to-end, holistic view across multiple sites. The bottom-up approach relies on improvement suggestions from all employees, usually through improvement teams, kaizen events, or employee suggestion systems. Many improvement ideas focus on ergonomics or safety, and managers routinely celebrate successes. This is a very powerful way to make sure that all employees feel empowered to contribute and improve the company’s performance. When successful, such efforts deliver not only improvements but also highly motivated employees. Notably, in our study of lean companies in Japan, where kaizen was pioneered, we found companies in which top-down and bottom-up approaches coexisted in harmony. (See Exhibit 2.)

Organization Structure. Fundamentally, the organization structure should support the company’s strategy and competitive environment. In an environment of large-scale change, it should also support internal change efforts. For example, in many decentralized organizations, strong and direct reporting lines to operations are needed to support lean programs. In lieu of direct reporting to operations, a strong governance structure should be in place to ensure that sites have the right incentives and support mechanisms. More important, organization structure at the site level should support the new requirements for rigorous leadership—particularly for frontline leaders.

Many companies find that they need to implement newer and more agile organization structures. These typically feature fewer and flatter levels of hierarchy but smaller spans of control at the front line and emerging team-leader roles that can fulfill the rigorous requirements of leadership, including real-time follow-up and continuous improvement initiatives on the shop floor. The right way to think about organization structure for lean change is to invert the traditional organization chart. The value-added work is done on the line, and all remaining functions and levels are support functions.

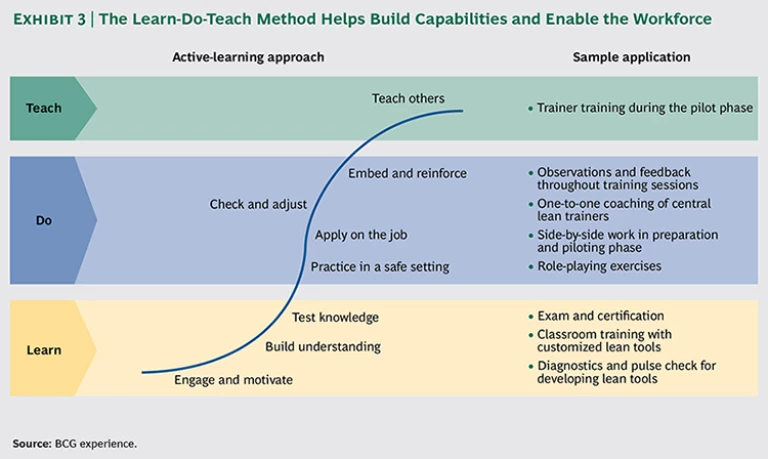

Capability Building. For change efforts to be successful, they need to be centered on people. By capability building, we mean training people to upgrade their skills and capabilities, as well as communicating with them and fully involving them in the change process. Unfortunately, some companies pay lip service to training and capability building, or they design well-meaning programs that are detached from the needs of the business. It is imperative to link capability-building efforts to the daily routines of managing performance, reacting to deviations, taking corrective and preventive action, and continuously improving through both top-down and bottom-up measures. In our client work, we often use a learn-do-teach approach to capability building. (Exhibit 3 shows an example of how BCG uses this framework during a typical project.) When organizations develop the capability to teach the new skills, the change effort becomes replicable. This is the most powerful tool for sustaining change.

Implementing lean sustainably in decentralized companies requires a high degree of rigor and standardization that come together in a companywide production system. Standardization does not imply rigidity, nor does it inhibit innovation. On the contrary, companies require a working baseline (a standard) to analyze and identify improvements and to ensure that the improvements will be respected. Winning companies empower their frontline leaders to spearhead the program. They then build strong change processes to ensure that the improvements take root and lead to stronger financial and operational performance, leaving the company better equipped to compete in the global arena.

Acknowledgments

The authors would like to acknowledge the contributions of their BCG colleagues Lars Fæste, Andreas Gocke, Paige Jackson, Matt Krentz, Sharon Marcil, Amyn Merchant, Moundir Rachidi, Ulrik Schulze, Hiroaki Sugita, Gideon Walter, and Michael Zinser.