Sustaining Value from an Advanced Digital Supply Chain

Now more than ever, supply chains need to be resilient, agile, cost efficient, and sustainable. Supply Chain AI by BCG X helps companies optimize on all levels—with no tradeoffs.

About Supply Chain AI by BCG X

Supply chains act as our connective tissue, supporting growth and sparking innovation. But increasingly, they are the source of challenges and constraints. Rising costs, shifting demand, critical disruptions—many companies are in a continuous cycle of assessing obstacles, identifying fixes, and hoping for the best.

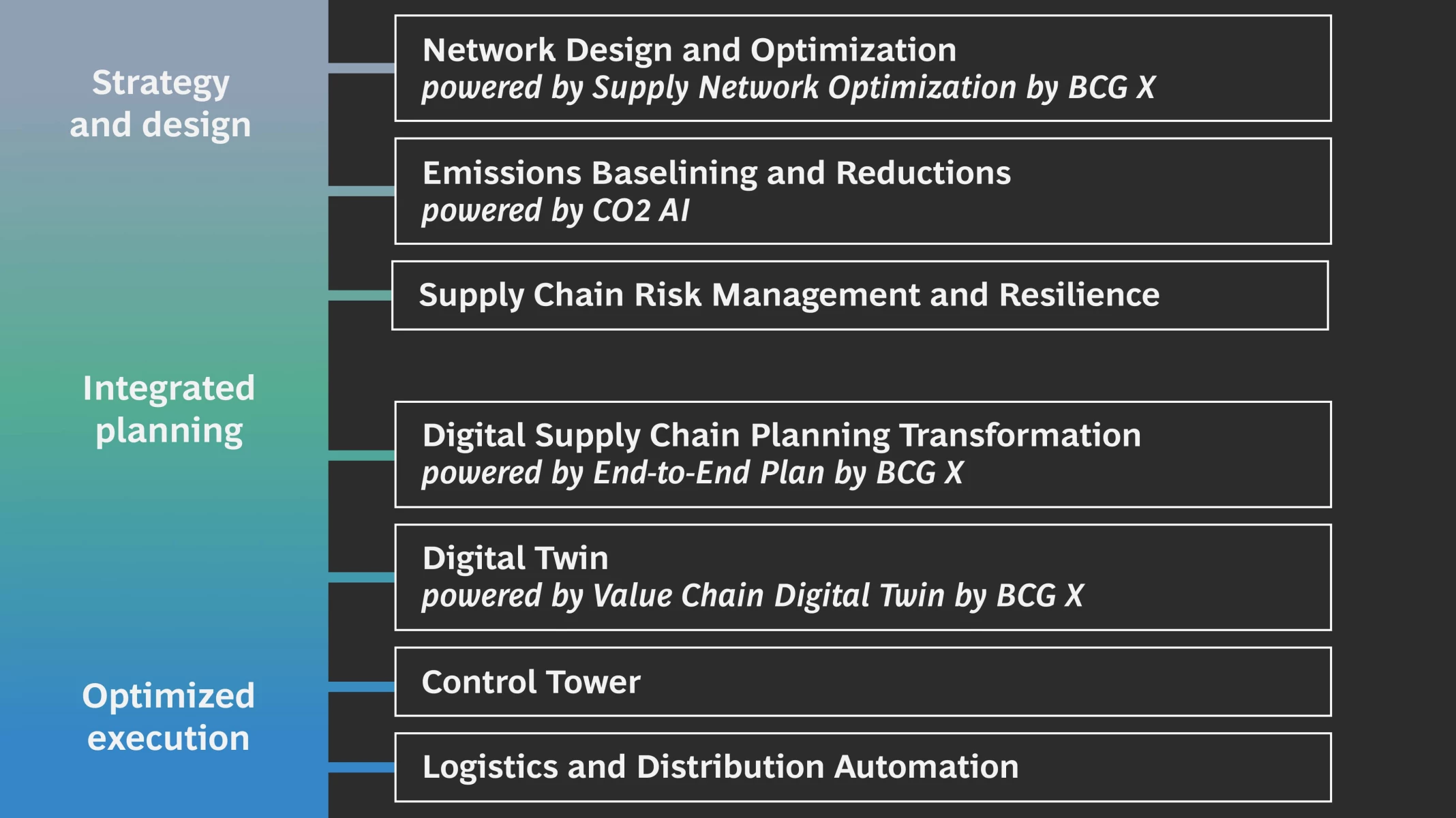

Supply Chain AI, our digital supply chain offering, lets companies return to creating value. A combination of digital assets, supply chain experts, and data science and engineering talent, Supply Chain AI takes a holistic approach to transforming a company’s supply chain, from strategy and design through integrated planning and optimized execution. Backed by a unique set of AI solutions from BCG X, we enhance seven key supply chain capabilities: network design and optimization, emissions baselining, risk management, end-to-end planning transformation, digital twin representations, control tower visibility, and logistics and distribution automation.

Supply Chain AI helps organizations build for the future, realizing not only the power of digital supply chain technologies but also their own full potential.

Combining People, Processes, and the Power of Supply Chain AI

Our digital supply chain consultants work in agile ways that bring out the best of both people and tech. Individual squads have expertise in, and accountability for, specific supply chain topics, and they focus on flexibility and enablement. We address gaps by building on top of existing solutions, realizing the full value of a company's data and in-house systems. We also draw on our world-class change management capabilities to ensure success, now and for the long term. Our customizable approach, fit to a client’s unique goals, follows a general paradigm:

Assess Current State

Define End State

Realize Value

Develop Foundational Capabilities

Launching New Transformation with Supply Chain AI

Supply Chain AI has a set of specialized AI solutions built by BCG X, that can be combined and customized in ways that maximize value—keeping the focus on the most important opportunities and issues. Each solution provides a rapid diagnostic to uncover high-value use cases, establishing a complete vision before recommending the right combination of people, processes, and technology. Supply Chain AI can be tailored to a company’s unique targets and benchmarks, and our digital supply chain consultants can build and deploy AI-enabled processes in any environment.

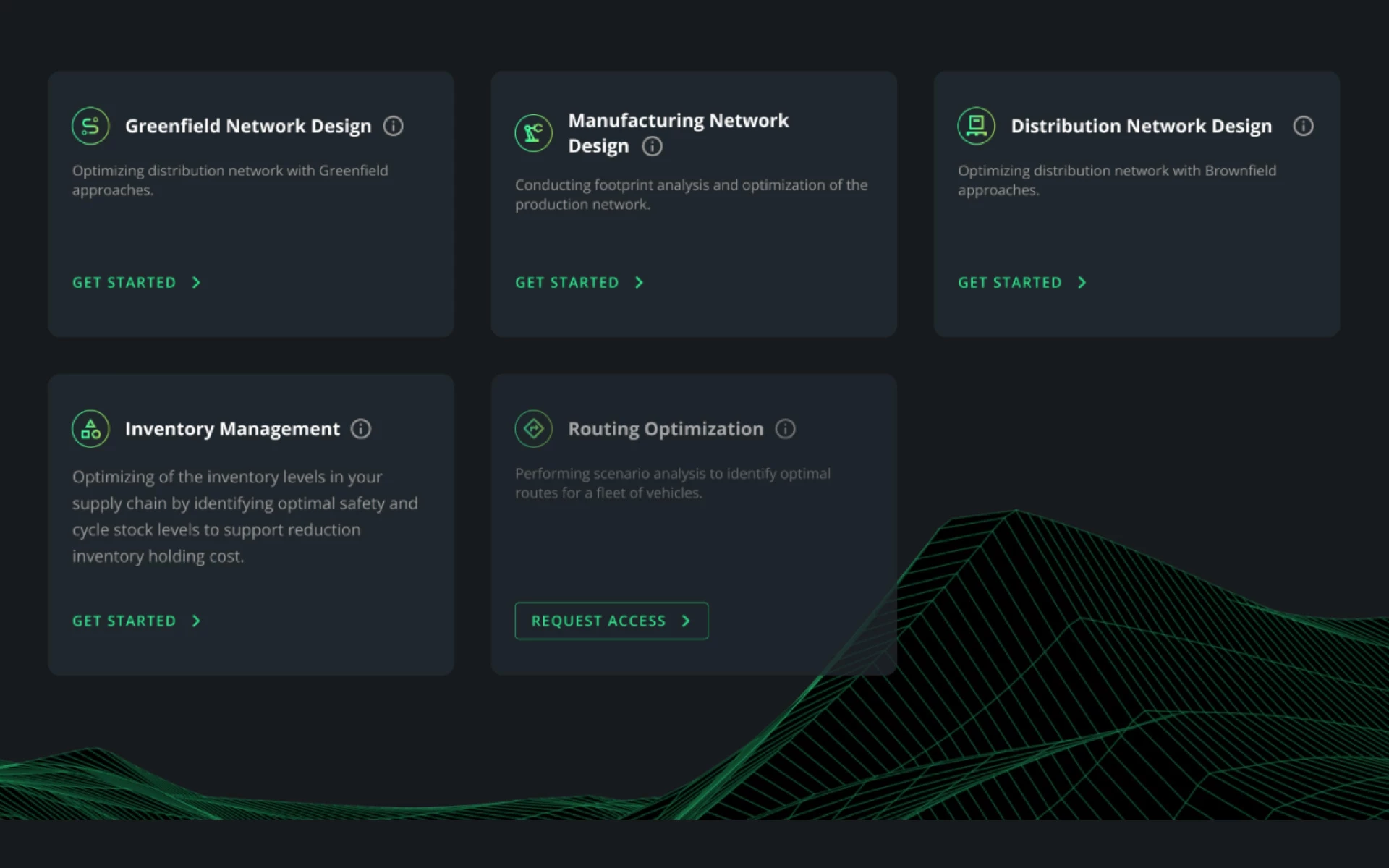

Network Design and Optimization

locations for factories and other facilities. It also fine-tunes the network through efficient assignments, transportation, and inventory allocation.

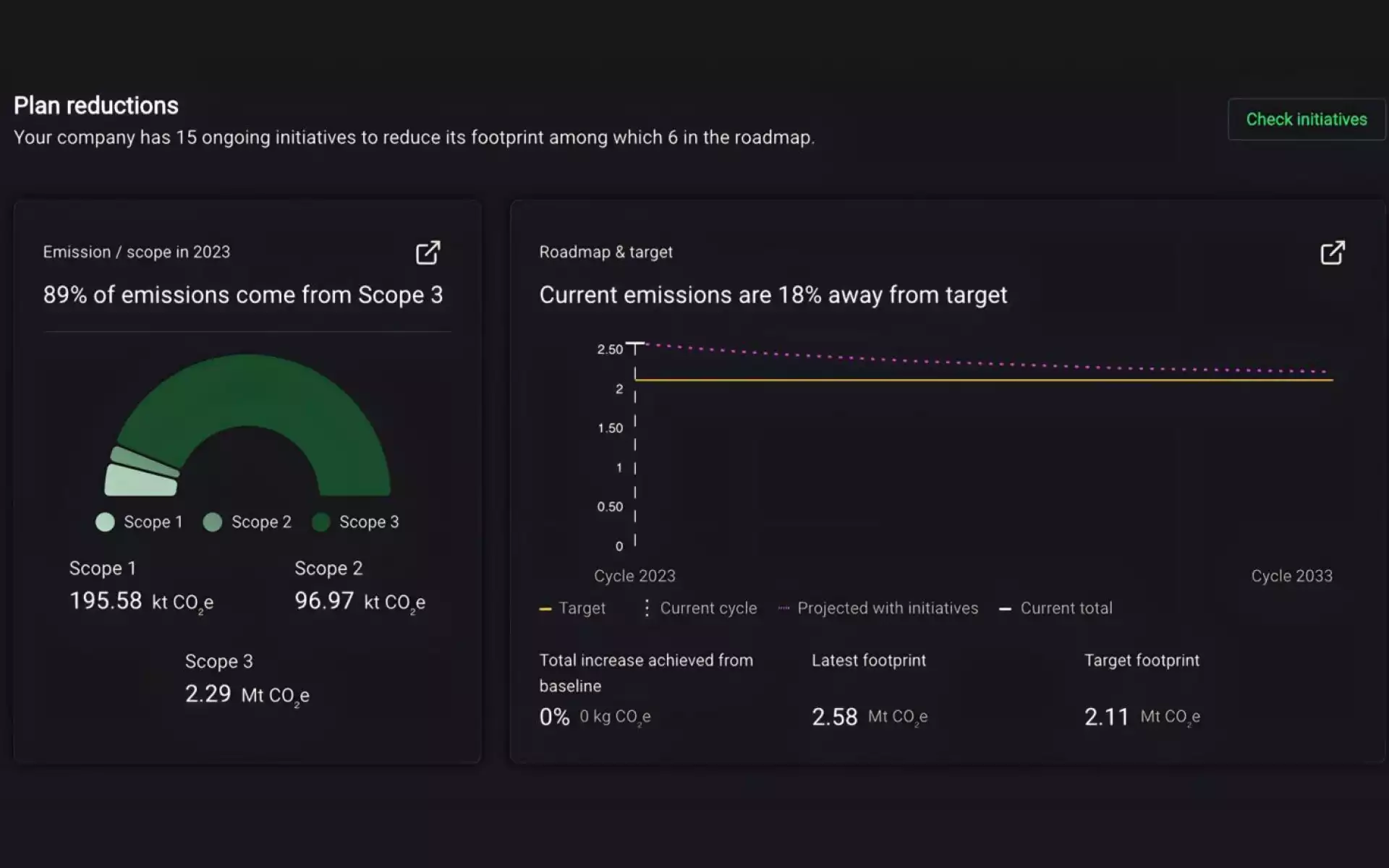

Emissions Baselining and Reductions

As companies accelerate their journey to net-zero, the supply chain has become a focal point for action. This Supply Chain AI solution uses CO2 AI—part of our partner ecosystem—to trace emissions across the supply chain, helping companies identify opportunities to shrink their carbon footprint.

Supply Chain Risk Management and Resilience

With this solution, companies leverage digital and AI-enabled business processes to enhance insights and decision making to manage risk. It features powerful technology to identify risks, for example, but it also blends the best of human and technical capabilities, so shocks don’t become disruptions.

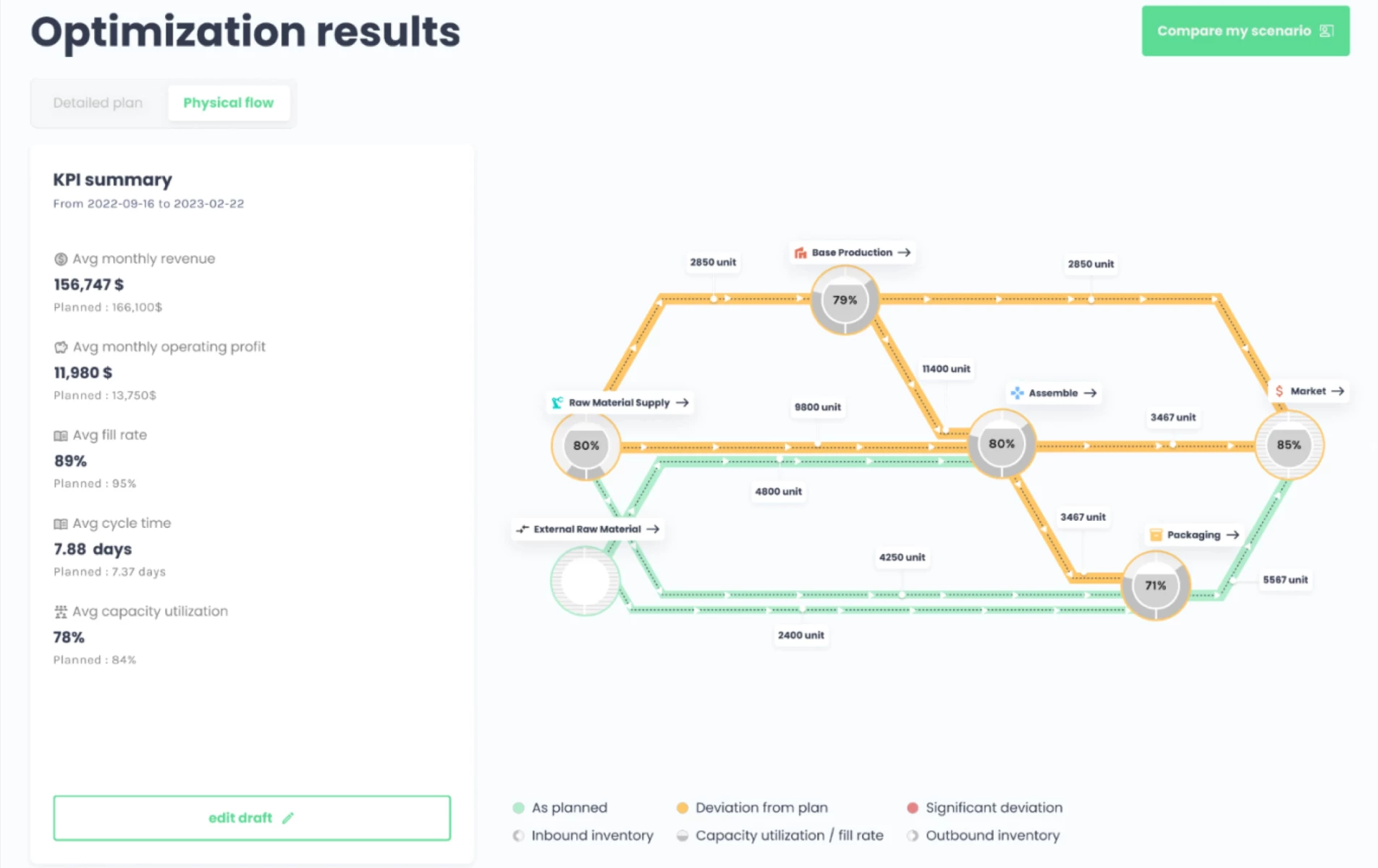

Digital Supply Chain Planning Transformation

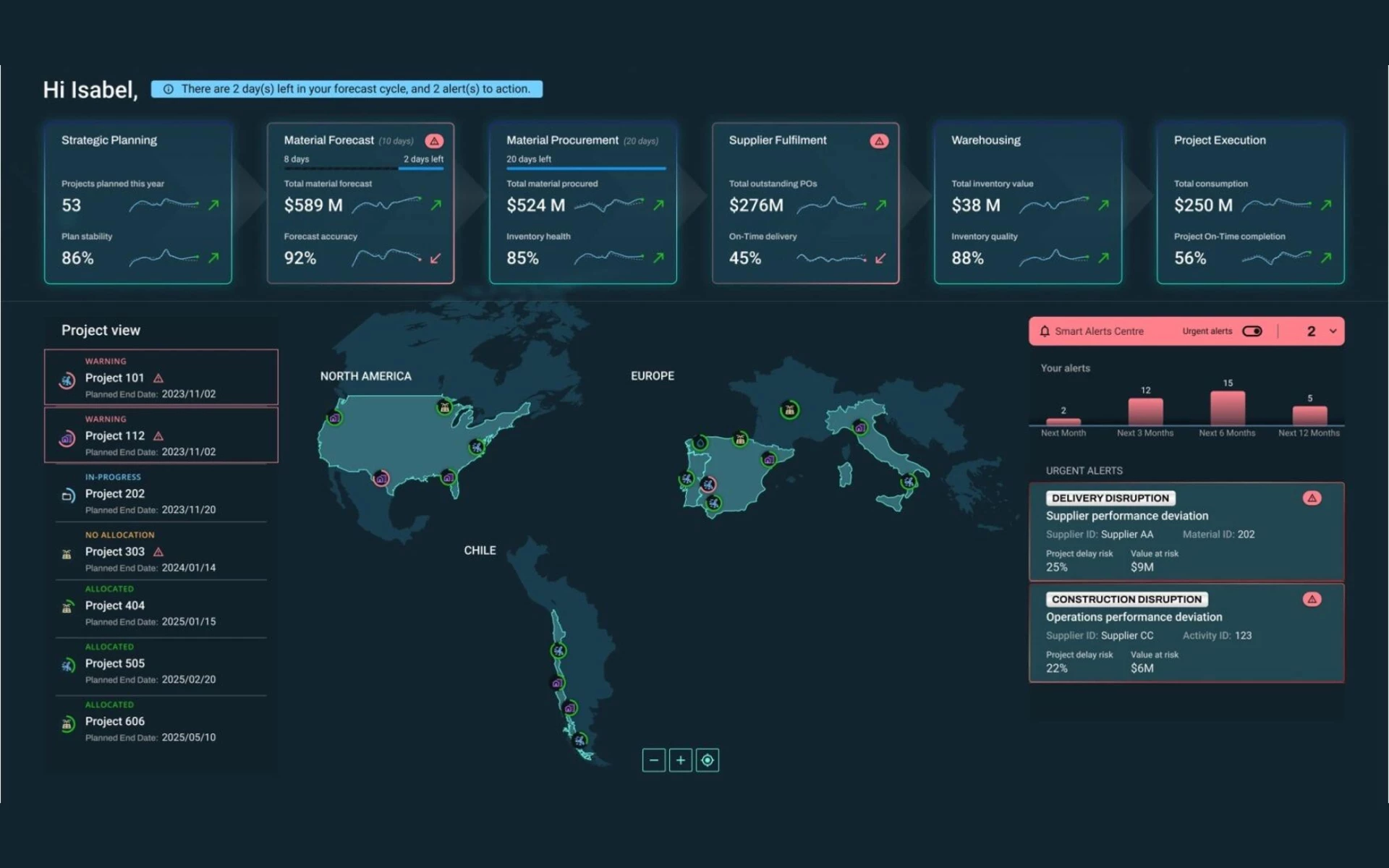

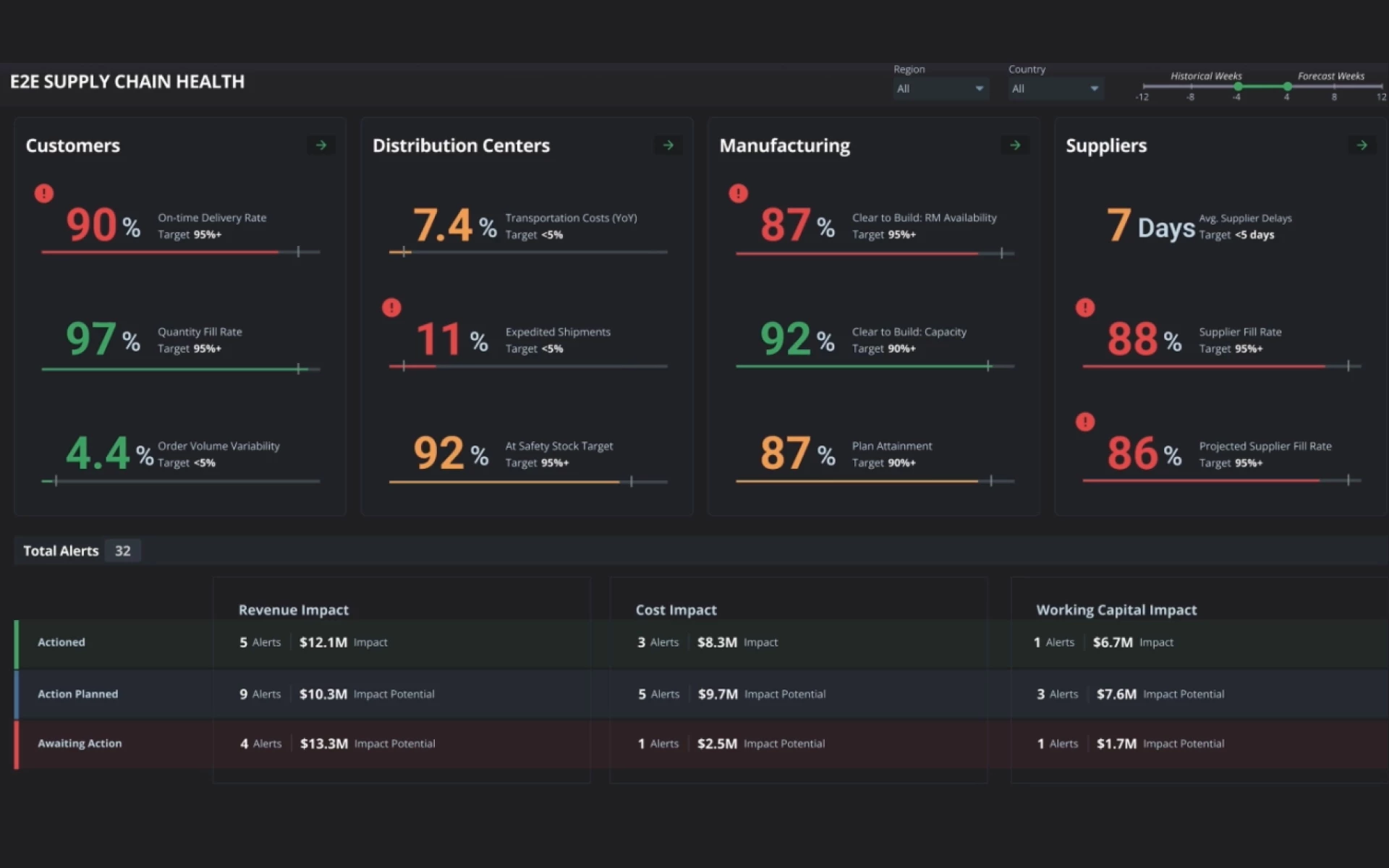

Powered by End-to-End Plan by BCG X, this solution addresses all key facets of end-to-end planning—including forecast, financial planning, and supply optimization. Leveraging proven cross-industry experience and transformative playbooks, it offers a scalable approach to re-engineer cross-functional processes while capturing service level, cost, and cash impacts.

Digital Twin

Powered by Value Chain Digital Twin by BCG X, this solution is customized for energy, heavy industries, and infrastructure players. It boosts the value and resilience of supply chains, providing end-to-end control through transparency, prediction, simulation, and automation.

Control Tower

This solution helps companies identify risks before they become crises. It reveals potential disruptions, such as supply constraints or shifts in customer demand, that businesses normally wouldn’t see in their internal data sets. Companies can quickly take action without skipping a beat—or a shipment.

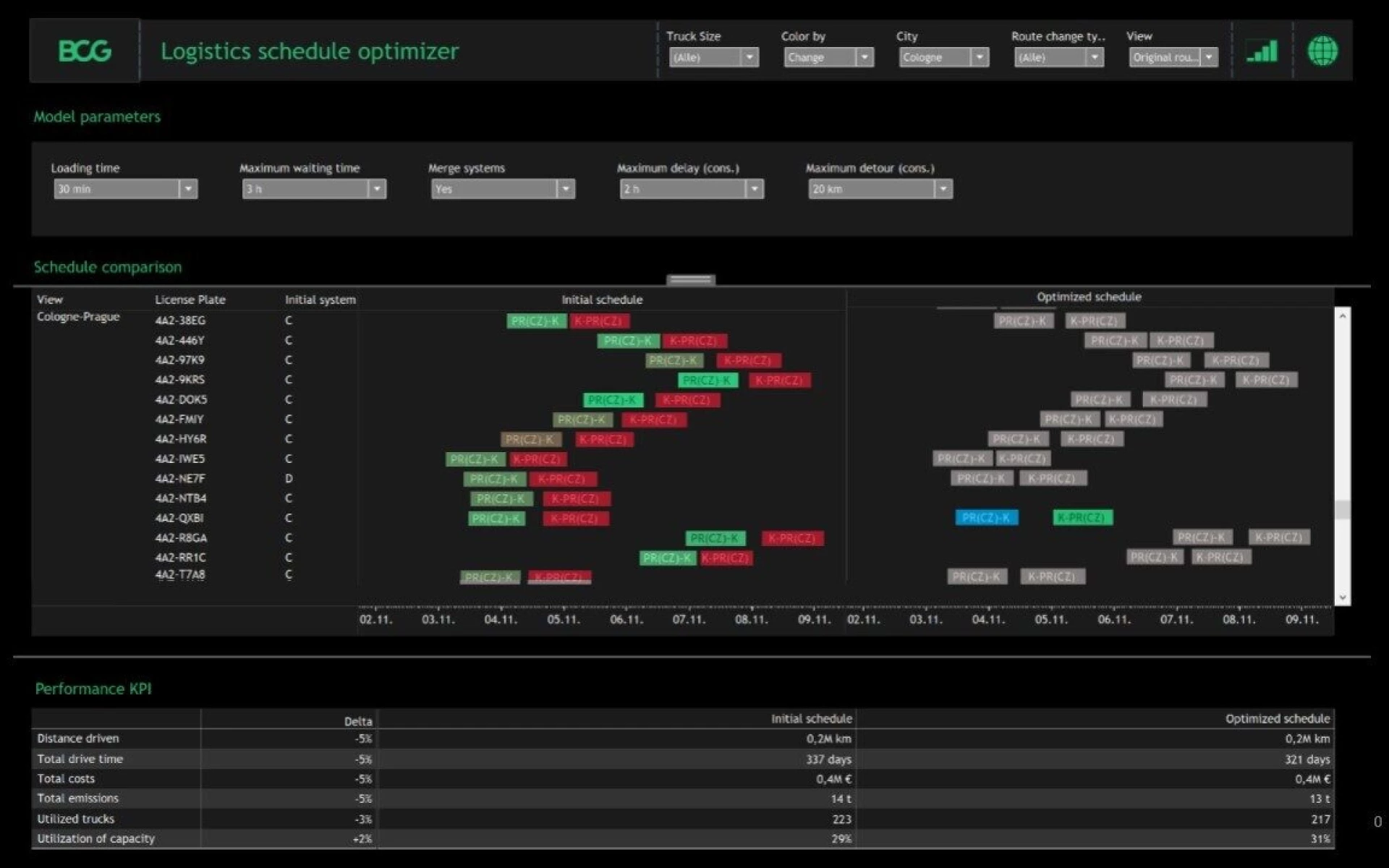

Logistics and Distribution Automation

Digital supply chain technologies can transform operations. This solution uses AI to automate warehouse tasks, streamline transportation processes, optimize scheduling, automate material flows, and fulfill orders quickly and accurately. The result: faster, leaner, and better operations.

Our Clients’ Success with Supply Chain AI

We’ve worked with businesses across industries and across the globe to help build the supply chains of the future. Here are some examples of our impact.

Explore Our Supply Chain AI Offering

Supply Network Optimization by BCG X

End-to-End Plan by BCG X

End-to-End Plan by BCG X

Value Chain Digital Twin by BCG X

Meet Our Supply Chain AI Consulting Team

Explore Our Insights on Digital Supply Chain