To survive in today’s environment of low growth and rapid product life cycles, companies need to consistently deliver products and services that provide both the greatest total value to customers and the most attractive economics over the entire life cycle. Design to value (DTV) is a cross-functional development process that achieves these dual objectives by translating top-level strategy into design choices for products and services as well as the underlying processes along the supply chain. DTV allows companies to focus their innovation efforts on the features that their customers are willing to pay for and to select cost optimization approaches that will improve and protect long-term profitability.

The Boston Consulting Group has developed a flexible and broadly applicable approach to DTV that companies in diverse industries can apply to both new and existing products and services. The approach is propelled by “catalyst events”—workshop sessions in which a team of cross-functional stakeholders apply a robust fact base to generate ideas for designing the best products with minimal complexity and cost. Companies bring together personnel from engineering, production, procurement, and sales and marketing for these events, thereby breaking down organizational silos and increasing agreement on strategic priorities across business functions. Some companies also involve their customers or suppliers.

For example, a consumer durables manufacturer applied a series of DTV analyses and catalyst events in order to turn around an unprofitable product category that had grown increasingly complex. The manufacturer began the process by determining the optimal offerings to serve its regions and sales channels, as well as the features that would be required to differentiate each product in its market. Teardowns of competitors’ products provided insight into how to reduce costs through product design choices.

With this fact base in hand, a cross-functional team convened to generate ideas for delivering the optimal product offerings with minimal complexity. The prioritized ideas included using modular systems and standard platforms across the broad scope of products. Next, the team considered ways to deliver the desired features at the lowest cost, such as by improving the supply chain and minimizing inefficiencies in production. Last, the team met with suppliers to identify additional cost-reduction opportunities, such as using lower-cost components or outsourcing. In less than two months, this initial DTV effort allowed the manufacturer to identify more than $80 million in savings. The subsequent embedding of DTV capabilities organization-wide allowed the company to reduce its long-term cost base by more than $2 billion.

A Multistep, Iterative Process

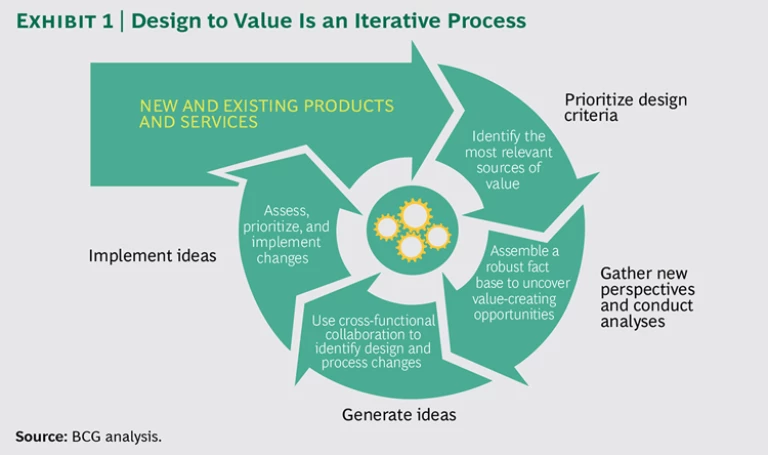

BCG’s approach to DTV entails four steps. (See Exhibit 1.) A company establishes its design priorities and then gathers a fact base to support decisions on design trade-offs relating to features and costs. Participants in catalyst events apply the insights to generate and rank ideas for design choices. Finally, the company tests and prioritizes these ideas and develops a plan for implementing them. The process is repeated at regular intervals to assess the need for changes to existing products and services as conditions change within the company or in the market.

Prioritize Design Criteria

The company begins the process by considering a wide range of potential sources of value and then identifying the design criteria that would promote the greatest value. Potential sources of value include the following:

- Serving new customer segments

- Serving existing customers better

- Reducing the total cost of ownership

- Streamlining the manufacturing process

- Meeting or anticipating new regulatory requirements

- Improving sustainability

- Improving product safety

- Improving cost competitiveness

- Improving product quality or durability

The design criteria for unlocking value may focus on changing the value proposition for customers (for example, designing to emphasize functionality, quality, safety, or efficiency), addressing important cost drivers (such as designing for ease of manufacturing, modularity, or simplicity), or improving both the value proposition and cost (for example, designing for reliability and service). Design criteria are often complementary or synergistic, so a company should think broadly about the design of products, services, and processes and how design choices can create or destroy value for its business. To take this broad perspective, the company must look beyond cost for new sources of competitive advantage that are best captured through design choices.

For example, a global food manufacturer identified an opportunity to create value and reduce total costs by improving the freshness of its products. To overcome supply chain bottlenecks that resulted in stale products on store shelves, a cross-functional team identified process and product-design changes along the manufacturer’s supply chain. These changes included emphasizing faster-moving goods in the product line, harmonizing ingredients among products, using more flexible manufacturing assets to allow for shorter and more frequent production runs, and obtaining a more accurate view of consumer demand. By implementing these ideas, the manufacturer reduced inventory by approximately 40 percent and formulation cost by more than 2 percent. The flexibility enabled by this optimization effort has also allowed the manufacturer to pursue seasonal trends in its product offerings.

In another example, a manufacturer of stainless steel, faced with a sharp decline in margins, determined that the redesign of its raw-material-sourcing process was essential for reducing costs and improving product quality. A cross-functional team pinpointed ways to increase the accuracy of the sourcing process, such as by using more dynamic data inputs and management approaches to respond to changes in commodity prices. To increase the flexibility of the sourcing process, the team identified and tested ideas for removing unnecessary restrictions on the choice of materials. The redesigned process is expected to reduce costs for raw-material purchasing and processing by 2 to 3 percent. The process includes variance monitoring to enable systematic tracking of actual versus expected savings over time.

Gather New Perspectives and Conduct Analyses

A company needs to establish a set of unambiguous truths to guide the idea generation discussions at catalyst events, spark new thinking, and provide evidence to push back on deeply held biases or entrenched views and practices. The new perspectives derived from consumer insights and competitor benchmarks are essential for developing this robust fact base.

Consumer Insights. A deep understanding of consumers and what they value is a critical input to the DTV process. A company needs a set of sophisticated tools and capabilities to uncover consumers’ motivations and decision-making processes. For example, BCG’s MindDiscovery approach, based on the latest psychological research and techniques, produces insights into why, and how much, consumers value specific product features and characteristics. (See “Data-Driven Insight: BCG’s MindDiscovery and More,” BCG article, July 2011.) The DTV process allows a company to translate consumer insights directly into design and process changes that improve both the value delivered to customers and the economics of products and services.

For example, a financial services company determined that a lack of standardization among services and inadequate data management were impeding its efforts to cost-effectively meet customers’ higher expectations and comply with more stringent regulations. The company applied consumer insights to segment customers on the basis of their requirements for service provision and data reporting. It then designed standard suites of products that allow it to meet each segment’s evolving needs more efficiently and effectively. The company also designed a highly scalable and adaptable operating model that enables it to capture more savings as its business grows and to continually improve the value delivered to customers.

Competitor Benchmarks. An understanding of competitors’ design choices and costs is another fundamental input to the DTV process. Competitor benchmarks provide clear evidence of alternative approaches to product design, forcing a company’s stakeholders to question their existing beliefs and practices. To capture the full potential of DTV, a company must conduct a comprehensive search for the most relevant and up-to-date benchmarks. Benchmarking efforts can be focused anywhere along the supply chain, from material inputs to the functionality delivered by the finished product.

Product teardowns are essential for assessing competitors’ products in detail, down to the level of their components or ingredients and the related manufacturing costs. (See “Teardowns Provide the Seeds for Idea Generation.”)

TEARDOWNS PROVIDE THE SEEDS FOR IDEA GENERATION

Teardown workshops, at which participants examine their company’s products and those of the company’s competitors side by side, can yield transformational ideas for design changes. By systematically taking apart a competitor’s product, participants gain critical insights about its design and cost and the value of its features. The objective is to understand why the company’s approach to design varies from that of its competitors and how those differences affect life cycle costs. Participants can apply these insights to conduct a “best of the best” benchmarking, set realistic cost targets, and identify the most cost-effective design solutions.

Issues to examine include the following:

- What parts are used? Are they made in-house or by a supplier?

- What materials are used? How does the choice of materials affect the product’s costs?

- In what sequence is the product assembled, and how are modules joined, linked, or fastened?

- What is the environmental impact, during both production and disposition, of competitors’ choices of parts and materials?

- Can we make design or component changes that will allow us to reduce the product’s cost or improve its functionality?

Three case examples illustrate the benefits of teardowns.

Uncover cost-reduction opportunities. A global consumer packaged goods manufacturer used teardowns to compare its bottle components with those of competitors. The teardowns revealed design, material, and assembly differences that pointed to opportunities to reduce costs by $20 million to $30 million for two of its brands.

Identify the source of advantages or disadvantages. A manufacturer of medical-technology equipment performed product teardowns to assess its position relative to its main competitor with respect to three design criteria: manufacturing cost, reliability, and serviceability. The teardowns revealed that the manufacturer faced a cost disadvantage of 8 percent for materials, direct labor, and manufacturing overhead. The manufacturer’s costs related to reliability (such as for parts and labor under warranty) were 30 percent higher. However, the manufacturer had a 10 percent advantage with respect to its cost to service its installed base. These insights provided the fact base for a DTV program that has the goal of reducing the manufacturer’s cost of goods sold by 20 percent.

Change perspectives. For a construction equipment manufacturer, tear-downs helped to radically alter internal perspectives on material costs and its products’ competitiveness. The teardowns identified the potential for overall cost savings of 8 percent, including savings of up to 25 percent in individual supply categories and 6 percent relating to the design of specific components. Equally important, the teardown exercise promoted mind-set changes that will yield ongoing DTV benefits.

For example, the design head for one product family acknowledged the inadequacy of simply reviewing brochures to understand a competitor’s product rather than closely examining the product itself. The head of R&D went further, acknowledging that the competitor’s product design was superior and that the construction equipment company needed “to do a lot of work” to catch up.

Generate Ideas

We have consistently found that cross-functional collaboration outside of employees’ usual work routines and environment is essential for generating the types of ideas that can truly transform a product’s value proposition. Catalyst events provide the forum for this cross-functional collaboration. In addition to internal participants, attendees should include experts from outside the company, to offer an external perspective and introduce new ways of thinking about value. By setting ambitious targets before events, a company can encourage participants to arrive motivated and ready to collaborate.

In brainstorming sessions, an event’s participants generate ideas about design improvements to a specific product, service, or process. Participants are encouraged to think beyond their individual functions and jointly uncover opportunities across the entire value chain. A focus on systems, rather than components, is critical to optimize both value and cost. The event’s facilitator should ask hard questions that challenge the status quo and illuminate the trade-offs in design decisions.

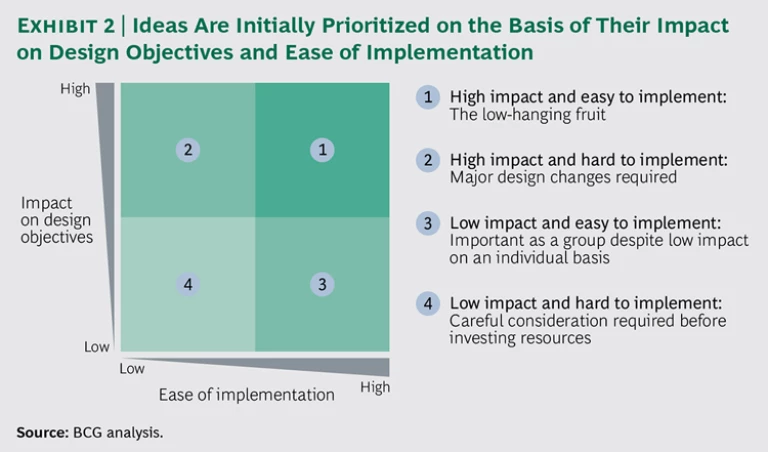

The ideas that emerge from a catalyst event are set out in writing and prioritized according to their potential impact on design objectives and ease of implementation. (See Exhibit 2.) Ease of implementation is based on the degree of engineering change required and its impact on customers and channel partners. This early ranking gives visibility to the best ideas and promotes participants’ engagement in the process.

Implement Ideas

A successful catalyst process will produce more ideas for design and process changes than are feasible to implement. The company must assess and test ideas at various levels of detail, so as to produce a prioritized list and, ultimately, an implementation plan for design changes.

At this stage, the company should prioritize ideas on the basis of a comprehensive business case. This prioritization requires a set of analytic tools that integrate various financial and strategic objectives to give a clear view of which DTV initiatives have the greatest potential to achieve the company’s goals.

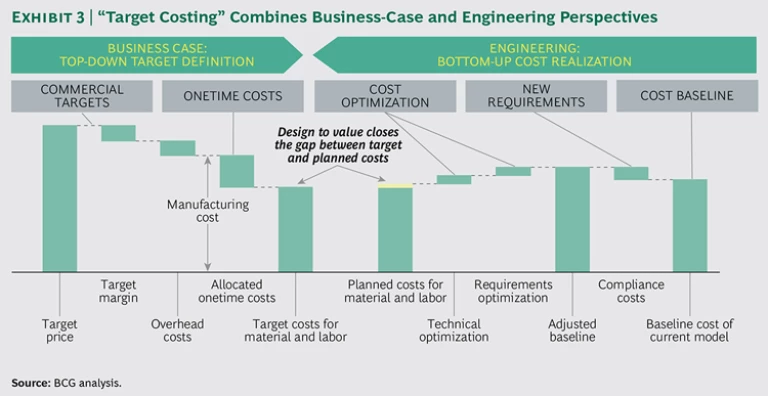

For example, a locomotive manufacturer used “target costing” based on business case requirements as the foundation for its DTV approach. (See Exhibit 3.) The manufacturer faced increasing cost pressures, because it needed to compete with low-cost market entrants and comply with new regulatory requirements.

A cross-functional team set a top-down target for material and labor costs by considering targets for price, margin, overhead, and onetime costs (such as for engineering and training). The team then identified a set of ideas for changes along the supply chain that would enable the company to optimize costs and meet the top-down target. These changes included using modularization and standardization to reduce the complexity of parts and applying insights from teardowns to remove low-value, high-cost features. The company also simplified its product catalog to better reflect trade-offs between feature costs and customer value. The effort yielded a 28 percent reduction in costs compared with the forecast baseline.

The Four Key Attributes of a DTV Culture

To fully capture the benefits of the DTV process, a company needs to instill a culture in which employees constantly question and update value propositions in response to changing consumer preferences, new regulations, and competitors’ innovations. In BCG’s experience, four attributes stand out as the essential characteristics of a DTV culture.

Taking a Cross-Functional Perspective

Collaboration across functions distinguishes companies that think DTV simply means conducting product teardowns from those that have embedded a culture that promotes value creation through product development. Taking a holistic, cross-functional view is the only way to accurately evaluate the level of complexity in a company’s product or service offerings or understand the strengths and weaknesses of an operating model or supplier strategy.

For example, to successfully apply teardown insights, a company must have a solid grasp of its product’s value proposition. And, to build a business case for addressing customers’ preferences, a company needs to understand the internal economics that promote profitability.

Focusing on the Value Opportunity

Companies that excel at DTV understand the value opportunities in their competitive environment, which allows them to accurately identify and prioritize design criteria. They think broadly about product and process design and how it can create or destroy value for their business. They also look beyond unit costs and incremental features for new sources of competitive advantage.

For example, new entrants disrupted the disposable-razor market by providing high-quality, durable razors that significantly reduce a customer’s total cost of shaving. Incumbents had opened themselves to attack by focusing on cutting production costs while adding features that customers were not willing to pay for.

Searching for New information and Insights

Information and insights that demonstrate the need for, and potential benefits of, design changes are essential to persuade participants at catalyst events to reconsider their traditional ways of thinking and adopt different perspectives. Companies with a true DTV culture develop their own databases of consumer insights or partner with experts on a regular basis to gather these insights. They reconcile conflicting sources of information and establish “one truth” as the basis for decisions. They are also willing to invest in knowing their customers and what creates value for them. Their procurement strategy is based on an up-to-date, holistic understanding of their suppliers’ competitive environments and opportunities to collaborate to create value.

Establishing a Collaborative, Repeatable Implementation Process

We have encountered many companies that have generated breakthrough ideas that ultimately end up gathering dust on the engineering department’s shelf. To implement DTV initiatives, companies must overcome the same organizational and cultural barriers that are common to any transformation effort in a large company. Successful companies extend the collaborative, flexible culture of catalyst events to their efforts to implement ideas and monitor the resulting changes. They invest in dedicated resources for DTV, such as a program management office (PMO), and develop an implementation process that can be replicated for all programs.

Building and Embedding DTV Capabilities

To promote long-term benefits, companies must help employees build the capabilities required to independently and consistently apply a value perspective to product design in a collaborative, cross-functional environment. The goal should be to transition from early, top-down mandates to broad-based change, with DTV as part of a continuous improvement mind-set.

A combination of formal sessions and side-by-side coaching can be used to introduce the overall DTV methodology and an approach to conducting product teardowns, including the most critical data and questions required for analyses. Employees can also be trained on best practices for setting up and conducting effective consumer interviews, focus groups, and quantitative surveys.

To ensure that the development process does not result in an accumulation of non-value-adding complexity, a company should require teams to apply DTV analyses at all product-development checkpoints and at each stage gate. To establish visibility into execution management, a PMO or other responsible party in the product development organization should be accountable for achieving DTV-related goals and report on progress directly to C-level executives. The company should also establish productivity targets and incentives that link performance management to DTV objectives.

Getting Started

At a company with limited DTV experience, early projects will likely result in quick wins, such as reductions in cost or complexity or improvements to the supplier strategy. A company can use the excitement of these early successes to build momentum and buy-in for broader changes company-wide. It can also use the cost savings to fund an ongoing DTV transformation program. To assess its starting point on the journey, a company should consider the following questions:

- How well do we understand our customers and what they consider to be valuable in our product or service offerings?

- How well do we understand our competitors’ offerings? Do we have competitive advantages or disadvantages with respect to cost or other design criteria, such as reliability and quality, as well as total life-cycle costs?

- Which quick wins could we target to build momentum and fund a broader DTV effort?

- How can we free up the funding for future investment?

- How can we maintain the support of the board, investors, and other stakeholders?

For many companies, the answers to these questions will point to opportunities to thoroughly review their approach to designing products, services, and processes. As competition intensifies in many markets, it has become imperative for companies to balance features, complexity, and cost to deliver the products and services that customers want, at a price that customers are willing to pay. Companies that successfully apply DTV to make these trade-offs will unlock value for their customers and themselves and be on the path to sustained, profitable growth.

Acknowledgments

The authors thank Shishir Agarwal, Michelle Andersen, Michele Brocca, Holger Gottstein, Hadi Zablit, and Michael Zinser for their insights and support.

They also thank David Klein for his writing assistance and Katherine Andrews, Gary Callahan, Catherine Cuddihee, Angela DiBattista, Kim Friedman, Abby Garland, and Sara Strassenreiter for their contributions to the editing, design, and production of this report.