The good news is that—according to the Science-Based Targets initiative—the number of companies setting near-term emissions reduction targets has grown nearly tenfold since 2020. At the same time, however, our own research shows that just 11% of companies have delivered on their emissions targets over the past five years.

That’s a problem. Leaders at every company must execute on their carbon abatement and other sustainability commitments if they are to maintain their credibility with increasingly impatient customers, investors, regulators, and other external stakeholders. And many companies recognize that meeting their performance goals isn’t just a matter of gaining a “license to operate.” The most progressive are trying to gain competitive advantage by placing sustainability at the core of their strategies and business models—by capturing a “green premium,” for example, or achieving superior operational resilience.

But capturing value through sustainability while meeting climate goals and related ESG objectives such as biodiversity, community welfare, and optimized water use, is no easy task. It requires a CEO and an executive team that believe in the opportunity, have a clear vision for capturing it, and are firmly committed to the goal of fully embedding sustainability throughout the organization’s operations and ways of working—everything from R&D to production to marketing. This effort can be especially difficult for companies in the materials and process industries, such as chemicals, mining, steelmaking, and papermaking, owing to their large-scale, resource-intensive operations and often global presence.

To shed light on the barriers that prevent companies from becoming more sustainable faster and to explore pathways for acceleration, we interviewed 48 representatives from 19 companies in materials and process industries, with roles ranging from chief sustainability officer (CSO) to asset-level manager. Their input suggests that the most advanced companies embed sustainability in their core ways of working through six key mechanisms. Together, these mechanisms can help make sustainability as natural a component of corporate operations and culture as profit-and-loss statements.

A Path to Sustainable Operations

The first step in integrating sustainability into operations is to identify in detail the impact that the effort to achieve sustainability will have on a company's operating model. Exhibit 1 lays out the elements of a typical operating model, together with the required enablers, and indicates how and where sustainability should be incorporated. A corporate strategy informed by a vision for a sustainable future is central. Everything else—from decision-making processes and incentive structures to data collection and corporate culture—radiates from there. As the CSO of a global chemicals company put it, “I consider my job done when there is no longer the need for a large central sustainability team. Sustainability should be fully embedded in our company’s DNA, just like how we view profitability today.”

“Sustainability should be fully embedded in our company’s DNA, just like how we view profitability today.”

—CSO of a global chemicals company

Unfortunately, many companies find it difficult to fully embed sustainability into their operating models. More than 70% of the executives and managers we interviewed highlighted the need for further integration of sustainability efforts into their day-to-day processes and decisions.

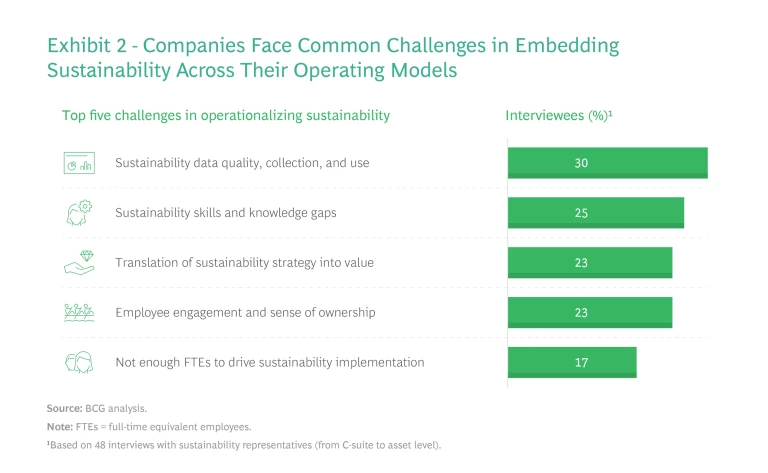

Several common challenges stood out in our survey and interviews, regardless of which industry the respondents worked in or how big their companies were. (See Exhibit 2.) Topping the list is the difficulty of collecting and using high-quality ESG data. Almost as challenging is the change effort required to develop a baseline understanding of sustainability across the firm and to convince all stakeholders that sustainability is a value opportunity and not just a cost driver.

Key Success Mechanisms

There is no single preferred operating model: every company’s operating model is different and reflects such factors as company ownership, business model, and geography. Nevertheless, our research shows that the most advanced companies have used six crucial mechanisms to make progress on their sustainability journey, as detailed in the following sections.

Understand and Demonstrate the Sustainability Business Case

Developing a strong business case for sustainability and articulating it clearly across the organization can be difficult, especially for companies operating in markets where the pressure to comply with sustainability requirements is still relatively light or where the definition of a “green product” is not yet clear.

To overcome these obstacles, companies must tighten the links between their corporate and sustainability strategies, recognizing the need for an integrated view. Much of the new value of sustainable products will arise from selling their sustainability profiles—their carbon footprint, for example—through certificates and audits. Companies should internally communicate all commercial sustainability success stories, such as a major contract closed thanks to a product’s carbon abatement profile, as well as the specific value-add gained.

For example, a large European metals company aims to fully integrate sustainability into the company’s corporate strategy by having the sustainability function report directly to the corporate strategy team. The teams work closely together, running reviews of the product portfolio to determine which products the company will have to sustain, improve, or close in order to serve green markets. The sustainability team also works closely with customer-facing teams to identify the value-add opportunity in sustainability: “We do not just sell a low-carbon product,” says the company’s head of sustainability. “We provide the service of assurance and transparency, and we need to set up our processes accordingly.”

“We do not just sell a low-carbon product. We provide the service of assurance and transparency, and we need to set up our processes accordingly.”

—Head of sustainability at a European metals company

Set Up Sustainability Communities to Co-create Targets and Solutions

Improving sustainability performance requires collaboration across organizational boundaries. Although top-down targets are important in defining ambition and direction, achieving wide and active engagement requires all employees to understand how they can contribute.

To promote engagement, a sense of ownership, and sharing of best practices, companies should set up cross-functional sustainability communities at both the corporate and divisional levels. These teams should actively collaborate on sustainability topics such as initiative development, internal communications, and upskilling programs. At the same time, however, strong governance mechanisms are essential to manage these and other sustainability-related tasks effectively and to ensure clear accountability.

To support its sustainability strategy, formalized in 2021, a large Europe-based paper and packaging producer set up several cross-functional sustainability working groups. At the highest level, the sustainability steering committee, which includes all the top managers across every business area, signs off on overall strategy and targets. The sustainability project management office, consisting of representatives of the sustainability and finance teams, maintains a central overview of sustainability performance and progress. Finally, dedicated working groups oversee each sustainability area—including water, waste and circularity, and emissions—as well as cross-functional topics such as internal communications. Each working group combines management and topic experts as well as key members from the production plants, who together align on and drive implementation of all sustainability initiatives.

Hard-Wire New Sustainability Processes into the Organization

Implementing sustainability programs requires a significant number of new processes, such as adhering to new sustainability policies and measuring and managing each product’s carbon, water, and waste footprint. Initially, many of these processes will not be well defined and will lack clear governance.

To put new sustainability processes in place, companies should first identify the necessary sustainability targets, policies, and regulations. They should break each new process down into actionable subtasks, with KPIs specific to sustainability goals, and allocate each one to the relevant department. Then they should hard-wire the KPIs into day-to-day operations by updating job descriptions, allocating sufficient resources to them, and integrating them into performance plans and incentive schemes.

After renewing its sustainability strategy, a North American packaging producer found that many of its employees were engaged in putting the new sustainability processes into practice, but no one was accountable for completing their implementation. So the sustainability team chose ten of the most important KPIs and appointed owners from across functions within the sustainability management committee for each one. Each KPI owner is now responsible for reporting on the assigned KPI, and some KPIs—including emissions reduction—are linked to compensation. “When sustainability is everyone’s responsibility, the risk is that it becomes no one’s accountability,” says the company’s vice president of sustainability.

“When sustainability is everyone’s responsibility, the risk is that it becomes no one’s accountability.”

—Vice president of sustainability at a North American packaging producer

Identify and Address Asymmetries in Talent and Skills

Often, different business units and functions must deal with employees who possess different levels of maturity in their skills, understanding, willingness, and readiness to act on sustainability goals. For this reason, a company’s central sustainability team should not take a “one-size-fits-all” approach to rolling out sustainability strategy, targets, and training.

First, the team needs to fully understand each organizational area’s level of maturity on critical sustainability topics. To engage teams and boost their sustainability expertise, the sustainability team should deploy targeted tools, including training on key issues and participation by local change agents who understand unit-specific nuances and can drive change from the bottom up. Then it should share knowledge and best practices from the more mature business areas across the organization through dedicated forums.

To ensure that every business unit takes ownership of its sustainability targets, the central sustainability team at a South American chemicals company rotates change agents across all of its local assets. These change agents are not directly responsible for implementing specific initiatives; rather, they ensure that sustainability is top of mind for local teams, and they provide guidance and training in various sustainability topics. They also share local feedback and knowledge with the central team—information that can be disseminated further.

Treat Sustainability Data on a Par with Financial Data

Maintaining complete and accurate data on sustainability initiatives is critical for tracking progress, informing strategic decisions such as capital allocation, demonstrating compliance to external stakeholders, and meeting regulatory disclosure requirements such as the EU’s Corporate Sustainability Reporting Directive. But effectively managing sustainability data poses real challenges: companies must align on methodology, collect the data, monitor its quality, and promote its use across the organization.

To achieve all these goals, companies should scrutinize this data as carefully as they do financial data—and consider making its collection and reporting the responsibility of the CFO. They should define clear data governance mechanisms and assign dedicated resources to collect, calculate, and share data on sustainability. To limit opportunities for human error, they should standardize systems for data collection and automate input wherever possible, through telematics on fleets and equipment, for example. Another practical step is to make the data regularly available to key decision makers, through monthly dashboards or other mechanisms. Finally, companies should arrange for external auditors to test the quality of the data.

It is critical to meet the data challenge head-on, as a North American paper and packaging producer did. Early in its sustainability implementation, the company discovered that it could not always trust its sustainability data. So it recently launched a program to improve data collection and quality, appointing dedicated employees to review and cleanse the data, hiring external data auditors, and developing a centralized interactive dashboard to support decision making.

To lessen the risk of human error and increase the frequency of data collection, the company also automates data collection wherever possible—by measuring energy usage in real time rather than simply analyzing quarterly energy bills, for example. “One of the key issues with sustainability data is that there is not as strong a culture for quality as we have with financial data,” says the company’s vice president of sustainability. “We have now been working for over a year to set up proper governance, clean up data, and build dashboards.”

Embed Sustainability Logic in Opex and Capex Decision Gates

Companies must link sustainability targets directly to critical opex and capex decisions. Any purchase of raw materials and other supplies affects Scope 3 emissions, for example, and capacity expansion investment impacts issues such as energy efficiency and water usage. All too often, however, companies decouple their sustainability programs from corporate planning and budgeting.

To avoid these issues, sustainability considerations must become part of all decisions involving opex and capex. First, companies should align their sustainability and corporate planning cycles, and then they should incorporate value-creation logic into sustainability planning. Investments should be prioritized on the basis of marginal abatement cost curves or an internal carbon price. Others take it a step further, calculating a “green EBITDA” and then applying an internal tax on a business area’s carbon emissions, which is collected and allocated centrally to support sustainability initiatives.

“Our job is to make sure that whatever we spend our money on aligns with the company’s overall vision, while at the same time creating value.”

—Director for program management at a North American packaging company

For example, the central planning team at a major North American packaging company approves all capital projects and oversees progress on sustainability targets. It evaluates and prioritizes all capex projects on the basis of their net present value per ton of CO2 abated—a calculation that includes value factors such as energy savings, efficiency increases, and green premiums. “Our job is to make sure that whatever we spend our money on aligns with the company’s overall vision, while at the same time creating value,” says the company’s director for program management.

Sustainability must now be a central element in every company’s corporate strategy, especially as it becomes an increasingly important source of value. The extent to which companies can capture this value depends on how well they set up their operating model for sustainability.

To understand where and how to embed sustainability into ways of working, company leaders should try to anticipate the requirements of the green markets of the future, the key barriers in the way of meeting those requirements, and the operating model changes that promise to have the greatest impact in addressing those challenges.