Our Approach to Operational Excellence

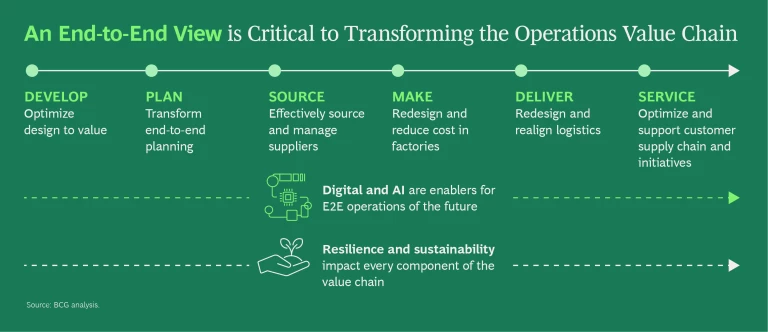

BCG’s operational excellence consulting teams help clients unlock efficiency and effectiveness by assisting with holistic value-chain transformation to enhance service and quality, reduce costs, and mitigate risks—guided by a tailored operational excellence strategy. We help organizations respond to unprecedented uncertainty by building resilience through competitive cost advantage.

How We Help Clients Achieve Operational Excellence in End-to-End Operations

Clients choose BCG as their operational excellence partner for:

- Unlocking new value fast—by zeroing in on the most promising operational innovation opportunities

- Tying operational excellence to business strategy—by aligning capabilities and performance to key enterprise strategies

- Sustaining success—by working with leaders across the organization to make sure that operational gains persist for the long term

- Strengthening their own capabilities—by equipping them with the digital tools, skills, and knowledge needed to tackle their toughest operational challenges on their own

- Optimizing the supply chain across functions—by breaking down silos and enabling transparency throughout the operational process

The result: a leaner, more agile enterprise that can flex as needed to win—not just now but also far into the future.

We are uniquely positioned to help clients extract maximum value from their operational excellence programs, bringing several core strengths to every project, including:

Global Integrated Teams

The 1,000-plus operations excellence consultants who make up our global network have a long track record of partnering closely with clients to help unlock new value from every aspect of their operations. Our team includes dedicated experts in operational cost consulting, generalist consultants with a focus on operations, senior advisers, and members of our operations centers of excellence. And our teams work closely with BCG X, the tech build and design unit of BCG that includes tech builders, designers, and entrepreneurs.

An Extensive Suite of Tools and Solutions

Through our comprehensive suite of tools and solutions, we help clients unlock value from every aspect of their operations, including transforming key business processes and optimizing supply chains. For example, we offer tools that enable clients to measure, track, and reduce their environmental footprint; diagnose inefficiencies in their design-to-value, sourcing, and manufacturing processes; identify ways to optimize their asset networks; and assess their digital maturity to pinpoint the most promising improvement opportunities. We also offer a spectrum of services in our Innovation Center for Operations around the world.

A Strong Track Record of Success

In recent years, our operational excellence consulting teams have completed more than 5,100 projects across industries and sectors as diverse as industrial goods, consumer packaged goods, financial services, automotive, health care, high tech, media, manufacturing, infrastructure, and public service. Drawing on insights gained from these projects, we regularly publish studies and articles that provide leading-edge, practical advice for clients seeking to take the next step in their operational excellence journey.

Our Operational Excellence Work with Clients

Our Operational Excellence Services and Tools

Competitive Cost Advantage

Competitive Cost Advantage

End-to-End Process Transformation (E2E PT)

End-to-End Process Transformation (E2E PT)

End-to-End Supply Chain (E2E SC) Optimization

End-to-End Supply Chain (E2E SC) Optimization

Supply Network Optimization by BCG X

Our Insights on End-to-End Operations