The pressure is on for manufacturers. But opportunity awaits those who rethink their approach to AI, efficiency, and operations.

Featured Insights

Manufacturing

Article

June 13, 2024

Realizing value at scale requires a sharp focus on people and processes, even more so than on the technology backbone and algorithms.

Article

September 21, 2023

Trade disruptions have prompted many global companies to shift where they produce and source goods. But getting the desired results requires a difficult balancing act.

Article

November 15, 2022

Building resilience and promoting sustainability while maintaining cost efficiency, service levels, and growth requires redesigning your network—and that will take several years. Better get started.

By leveraging data and advanced analytics, companies can provide better products and services, optimize their value chains, and maximize return on capital. Effective data-sharing applications are essential to define key success factors and to enable manufacturers to derive value from their data.

BCG-WEF Project: AI-Powered Industrial Operations

How can manufacturers harness the latest technologies to optimize for increased productivity, improved sustainability, greater resilience, and a stronger workforce?

Industry 4.0

Article

July 19, 2023

Organizations must use all their data, customize and link their underlying systems, and manage the transition patiently to get the best from the new breed of IBP platforms.

Article

December 5, 2022

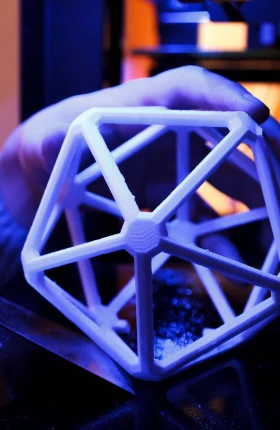

Combining distributed and additive manufacturing mitigates supply chain risks by enabling fully digital interactions, better economics for producing small quantities, and flexible capacity.

Article

November 8, 2022

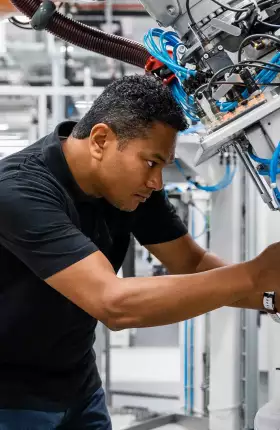

Higher levels of automation and flexibility help manufacturers offset labor shortages while boosting service and safety.

Video

July 14, 2020

The Factory of the Future

What does the future of manufacturing look like? BCG's Kristian Kuhlmann explores the dimensions of optimization shaping the next level of progress.

Supply Chain

Article

March 6, 2025

Companies have already taken steps to reduce costs along the supply chain. Further reductions require tougher decisions in several key areas.

Report

January 13, 2025

New BCG research forecasts dramatic changes in world trade flows in the coming decade as national alliances, rivalries, and aspirations rewire the global economy.

Article

February 6, 2024

With parallels to the complexities of building a house, BCG’s approach to transforming a supply chain emphasizes the importance of coordination, digital enablement, and speed.

Article

May 9, 2023

Companies often struggle to match decision-making speed with changing dynamics. That’s why a decision-led approach to end-to-end planning transformation is key.

Weekly Insights Subscription

Stay ahead with BCG insights on manufacturing

Sustainable Supply Chains

Article

October 30, 2023

By adhering to a simple six-step process, business can systematically manage ESG risks in global supply chains. Doing so will also embed ESG into the heart of operating models.

Article

March 27, 2023

Eventually, once the circular value chain is mature and optimized, secondary materials will cost less than primary materials.

Tackling Scope 3 emissions is essential to reach net zero targets. But Anastasia Kouvela explains how doing so goes beyond climate benefits: aligning leaders and driving innovation to create value and reduce costs.

Article

June 21, 2023

Supply chains generate 11.4 times more emissions than in-house operations, but only 39% of businesses engage suppliers on climate topics. Here’s how to engage them.

Building a New Manufacturing Landscape

Amid shifting dynamics, transforming the global footprint can improve companies’ resilience and sustainability and cut manufacturing and supply chain costs. How are successful companies doing it?

In this video, BCG’s Marc Gilbert shares his perspectives on an effective sourcing footprint transformation.

Many manufacturers in the region recently moved parts of their supply chain. Although the results didn’t always meet objectives, the successful transformations had three things in common.

From 2018 through 2022, China’s shipment of goods to the US dropped by 10%. Manufacturers in India and Southeast Asia are reaping the benefits of this change.

Explore more

Capability

Capability