Physical AI: Powering the New Age of Industrial Operations

Technological breakthroughs are pushing the boundaries of automation. Mechanizing tasks that were once too variable or cost-prohibitive to automate is now both technically feasible and economically viable.

Although traditional industrial robots are foundational to automation, they have long been constrained by limited adaptability and high integration costs. The new age of robotics is defined by intelligence and flexibility powered by the convergence of advanced hardware, artificial intelligence, and vision systems. Together, these advances are unlocking the next frontier of robotics.

Approaches such as training methods (reinforcement learning, imitation learnings) and multimodal foundation models for robotics, as well as dexterous hardware components (such as soft grippers and tactile sensors) are enabling robots to handle variability, reason in context, and adapt in real time. Simplified deployment, such as through virtual training and intuitive interfaces, is significantly reducing time-to-value and expanding accessibility to small and midsize manufacturers and logistics providers.

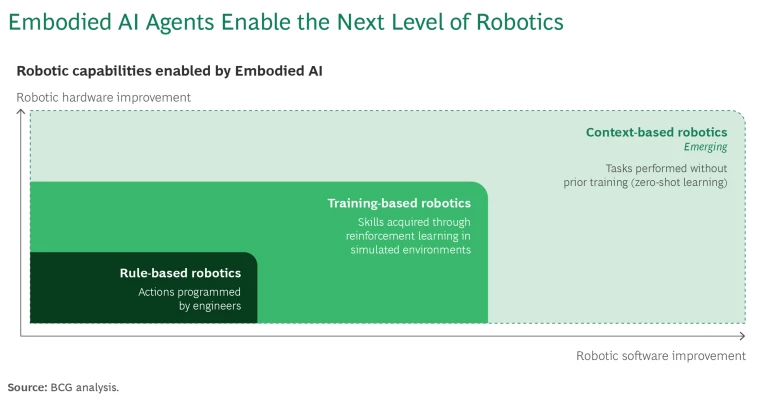

Such advances lead to three foundational robotics systems that will coexist in the future of industrial operations, together forming a layered automation strategy. These systems are complementary, each suited to specific combinations of task complexity, variability, and volume.

- Rule-based robotics, delivering unmatched speed and precision in structured, repetitive tasks (such as automotive welding)

- Training-based robotics, mastering variable tasks through reinforcement learning or imitation learning (adaptive kitting, for example)

- Context-based robotics, capable of zeroshot learning and execution in unpredictable processes and new environments (the robot receives, reasons, and acts on instructions via natural language)

Automation is expanding opportunities across the industrial value chain. Early adopters are already achieving significant results. For example, Amazon, operating the world’s largest robotics fleet, has demonstrated how the integration of mobile robots, AI-based sortation, and GenAI-guided manipulators can improve performance in fulfilment centers. By orchestrating these autonomous systems, facilities have realized 25% faster delivery, 30% more skilled roles, and a 25% boost in efficiency. Similarly, Foxconn applied AI-powered robotics and digital twin simulation to automate high-precision tasks such as screw tightening and cable insertion, previously considered too complex for automation. Through real-time adaptive force control and simulation-based deployment, the company cut deployment time by 40% and reduced operational costs by 15%.

However, realizing such outcomes at scale demands more than cutting-edge technology. It requires a future-ready automation strategy that incorporates both technical and organizational foundations:

- Embedding the emerging AI technology stack into the existing industrial toolchain and forging ecosystem partnerships across robotics, AI, and manufacturing to ensure interoperability, scalability, and continuous innovation.

- Workforce transformation through reskilling and upskilling to enable human–machine collaboration and prepare workers for emerging roles such as robot supervisors, AI trainers, and system optimizers.

Manufacturers and logistics providers that act now and embed robotics as a strategic asset will lead the next phase of industrial competitiveness, shaping a future in which intelligent automation becomes a cornerstone of sustainable growth, workforce empowerment, and systemic resilience.

Frontier Technologies in Industrial Operations: The Rise of AI Agents

AI agents have the potential to lead manufacturers toward a future of self-controlling, near-autonomous operations, unlocking opportunities in many industries. In the AI-centric factory, human workers will transition from hands-on operators to orchestrators, stepping in when judgment or creativity is required. This shift will boost operational efficiency, allowing people to focus on the strategic tasks and ethical decision-making that drive innovation and growth.

BCG has collaborated with the World Economic Forum, operations and technology executives, and academic experts on an initiative to support manufacturers in the adoption of AI agents. This work has focused on two types of agents:

Virtual AI agents enable software applications to achieve defined goals autonomously in the digital environment. These agents support workers and can independently control and steer processes and machinery. The maturity of virtual AI agents can be categorized into three levels: assistance, recommendation, and automation. The distinct objectives at each maturity level are pursued by specialist agents. Meta agents orchestrate specialist agents to achieve broader objectives.

Embodied AI agents equip physical systems, such as robots, with the ability to perceive and act within the physical environment, allowing for dynamic and complex movements. These advancements are overcoming the current limitations of robotic automation. Unlike rule-based systems that depend on manual coding, AI-enabled, training-based robotics can now acquire skills through reinforcement learning in simulated environments. Going further, context-based robotics built on robotics foundation models (RFMs) have a general understanding of the world. Because they require neither coding nor training, they can lead to a paradigm shift in robotics: zero-shot learning. (See the exhibit.) RFMs are undergoing rapid advancements, with breakthrough applications expected in the coming years.

Successfully navigating the transition to near-autonomous operations driven by AI agents requires a comprehensive, value-driven approach to technology adoption. Solutions should be scalable and aligned with long-term business objectives. Establishing strong organizational and technological foundations that support this vision is a strategic imperative for manufacturers looking to capture their full potential.

AI-Powered Industrial Operations: AI Survey Results

The world of industrial operations is changing, and manufacturing companies are facing considerable challenges—including rising economic pressure, the sustainability imperative, volatile resource prices, and supply chain disruptions as well as increasing capability challenges and talent shortages. In this complex environment, the expanding role of data and advanced manufacturing technologies such as artificial intelligence (AI) offers companies new opportunities to address these challenges and to significantly augment industrial operations.

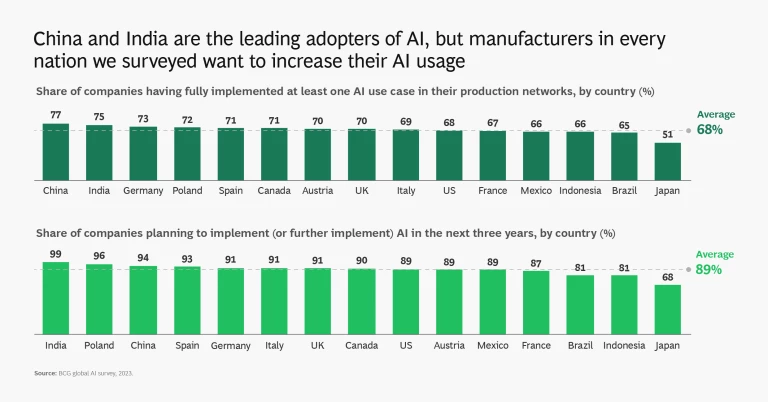

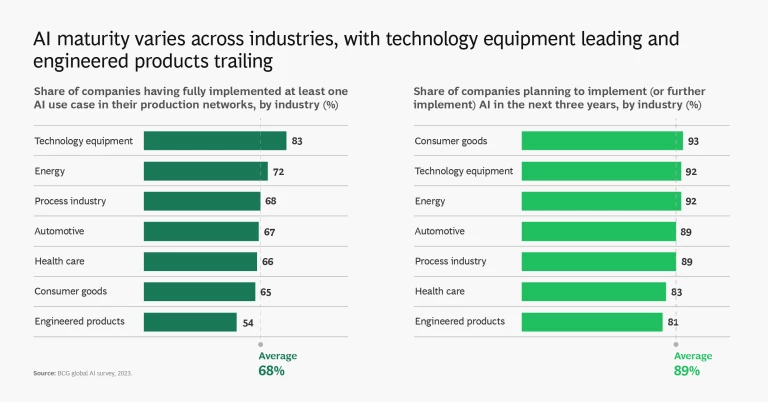

To evaluate the current state of AI within industrial operations, BCG conducted a global survey of almost 1,800 manufacturing executives. The survey covered seven different industries across 15 nations worldwide.

What We Learned

Here are five key takeaways from the survey:

- AI is highly relevant to industrial operations: 89% of companies plan to implement AI in their production networks.

- AI is boosting production efficiency: early adopters saw 14% savings on addressed manufacturing costs.

- Adoption is increasing: 68% of companies have already started implementing AI solutions.

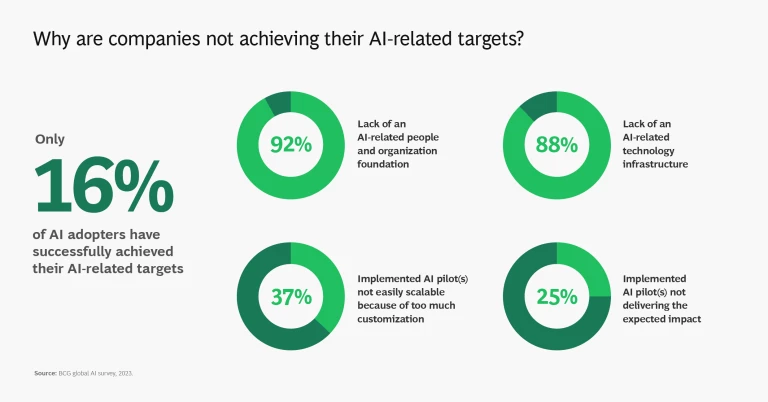

- It’s not a sure-fire success: only 16% of companies have achieved their AI-related targets.

- Scaling is particularly difficult: 98% of companies face challenges scaling their AI solutions.

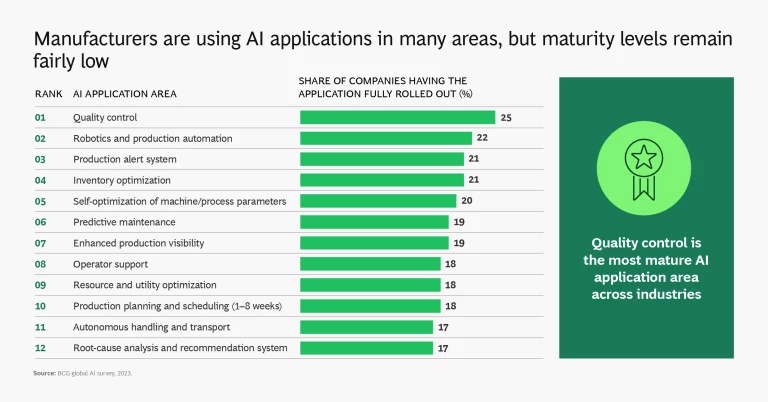

Among our other findings: Manufacturers in China and India lead those of other nations in terms of AI maturity, while among industries, technology equipment manufacturers are most mature in their use of AI. Quality control, robotics and production automation, production alert systems, and inventory optimization are some of the leading AI use cases for industrial operations, according to the study. But even the most common use cases were relatively immature—25% or less of the companies surveyed had fully rolled out those applications.

When it comes to the barriers to scaling AI throughout their production networks, 88% of executives named a lack of AI-related technology infrastructure as a major challenge, with data processing (34%) and visualization infrastructure (34%) being the most common areas of concern. Meanwhile, 92% of executives said the lack of an AI-related people and organization foundation was a challenge, with a shortage of digital skills and capabilities (39%) and the lack of an AI strategy and roadmap (33%) being cited most often.

The survey results underline both the relevance and potential of AI for industrial operations. Manufacturers who act now to incorporate AI solutions can gain a significant advantage in addressing today’s challenges, while those who delay risk falling further behind.

Meet the Project Advisors

Related Project Content

Read the full article