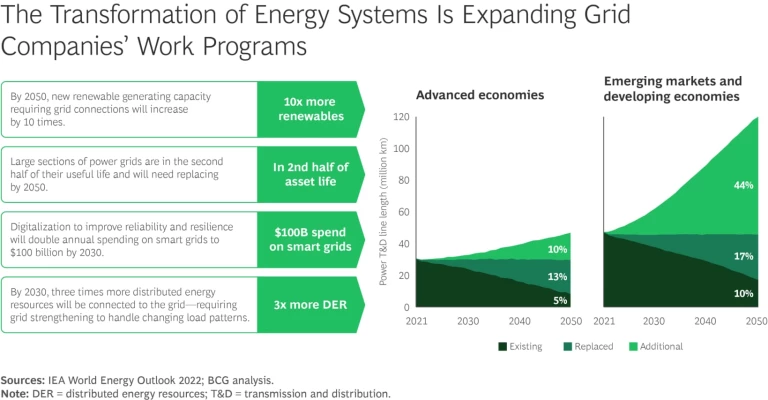

The transformation of global energy systems is forcing electricity network companies to build up their assets. Faced with growing demand from electrification and data centers, new supply from renewable energy sources, and greater emphasis on reliability and resilience, companies are having to add new grid connections, upgrade their existing capacity and leverage smart digital solutions.

As a result, grid operators face significantly larger work programs. These programs, which consist of new-build projects as well as maintenance and replacement jobs, can be two to five times greater than they were in the past.

Stay ahead with BCG insights on energy

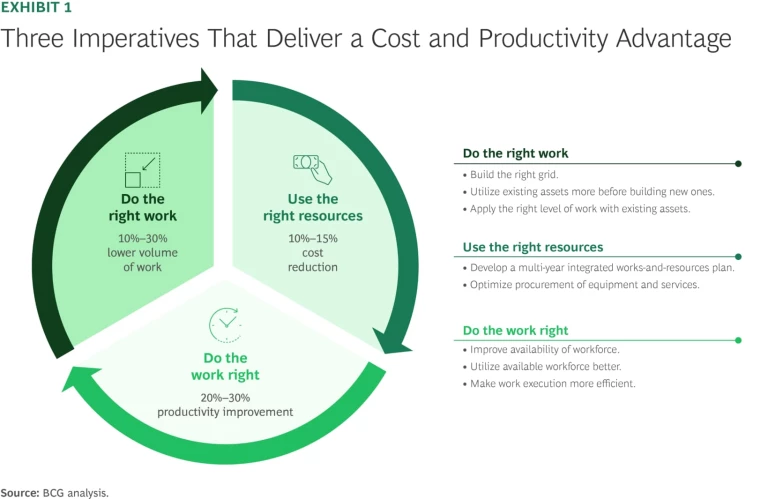

To satisfy the increasing demands they face in a constrained environment, network companies need to significantly improve their productivity. (See “Challenges Energy Networks Face.”) This article casts fresh light on the three imperatives that can help grid companies to achieve a step change in productivity—and examines how leading network players today are using technologies that include AI and data capabilities to implement these imperatives:

- Do the right work.

- Use the right resources.

- Do the work right.

CHALLENGES ENERGY NETWORKS FACE

- Constraints on the availability of critical equipment, services, and skilled workers

- Pressure to control spending to manage the ensuing rise in customer tariffs

- Challenges raising the money to pay for their massive capex requirements

- The need to maintain quality of supply and minimize disruptions to existing customers

Put simply, by doing the right work, companies avoid doing unnecessary tasks and can reduce the volume of work by 10%–30%. By using the right resources, securing resources at an optimum time, and paying an adequate price for them, they lower costs by 10%–15%. Finally, by doing the work right, companies perform the necessary work more efficiently and improve their productivity by 20%–30%. These efforts act in a self-reinforcing cycle: less demand for work can help with securing the optimal resources, and knowing what work is coming helps players to organize the work better. (See Exhibit 1.)

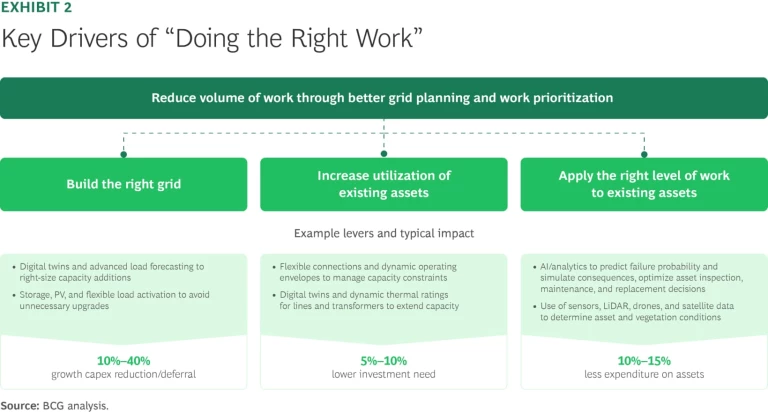

First Imperative: Do the Right Work

Doing the right work means building the right grid that supports new demand and generation sources, with upgrades delivered by the time they are required. It also involves utilizing existing assets more fully before building new ones; and adopting a risk-based approach to asset management to apply the right level of inspections, maintenance, and replacement work to focus resources on the highest priority work. (See Exhibit 2.)

Build the right grid. Building grids that support growing and more volatile electricity demand and greater penetration of distributed energy resources requires players to rethink how they plan their networks.

Rather than overbuilding the grid to meet the highest peaks and lowest troughs, networks need to adopt alternative solutions that reduce the impact on grid assets while keeping customer bills in check. These solutions can include, for example:

- The colocation of supply and demand (solar PVs, batteries, EV chargers, or other load) to reduce the need for grid usage

- Demand flexibility measures to encourage customers to use electricity when it causes the least stress to the system or can absorb surplus renewable energy

- Flexible connection agreements for generation and load customers

Through these levers, some grid companies are reducing their future growth capex requirements by between 10%–30%.

Here are some examples of the innovative work that players are doing in this space.

Falbygden Energi, a Swedish distribution company, needed to connect a 20 MW solar farm to a substation that already hosted a wind farm with a similar capacity. If both generators produced energy at the same time, they would exceed the 20 MW maximum capacity that could be injected into the high-voltage grid at this location. The company used a digital twin of its network developed by Plexigrid to simulate the grid load at the connection point. It also examined whether the addition of a 20 MW utility scale battery would allow the connection to go ahead. Since the battery alone was not enough to stay within network constraints, the solution also involved introducing a flexible connection agreement requiring the solar farm to curtail production when the combined exports to the grid neared 20 MW. This approach resulted in a faster grid connection, increased total renewable generation in the area, and delivered a lower connection cost for the solar farm.

As part of future network planning in the Western Sydney area, Australian distribution network operator Endeavour Energy tested the impact of matching EV charging and rooftop solar generation—in time and location—on future network investment needs. Endeavour Energy identified that the adoption of EVs could lead to a potential increase in coincident peak demand in its network of ~ 0.6GW by 2040. In a scenario with highly responsive EV charging, matched with rooftop PV generation, the contribution to peak demand would reduce by ~50%. The ability of flexible EV demand to absorb surplus solar energy also mitigated the occurrence of overloads and curtailments in small distribution substations. Consequently, this approach by the year 2040 is projected to improve Endeavour Energy’s service levels by more than 60% and reduce the proportion of substations experiencing overloads from 70% to 30%. These findings translate into hundreds of millions of dollars in avoided network expenditure, coupled with improved asset utilization.

Increase utilization of existing assets. Digital solutions that simulate the behavior of assets using real-world and real-time data are essential for better asset utilization and to avoid unnecessary investments to increase their capacity. For example, leading networks are using data from SCADA, sensors, and smart meters to simulate transformer usage under different conditions. They are then able to introduce dynamic thermal ratings to dynamically change these assets’ operating limits depending on the weather and other parameters. With this approach, grid operators can increase their substations’ available capacity by between 2% and 9%.

A similar approach can be applied with dynamic line ratings as well. For example, Essential Energy, one of Australia’s largest distribution grids, leveraged a digital twin created by software company Neara to simulate its overhead lines’ behavior under different scenarios. The operator discovered that its long feeders could safely operate at higher currents and resultant temperatures than previously thought, allowing it to double the capacity in parts of the network and connect more renewables to existing lines.

In another case, Endeavour Energy needed to upgrade grid capacity so that the operator of a large bus depot could electrify its fleet. To estimate the potential for utilizing existing assets better, Endeavour installed sensors from Edge Zero on the distribution transformers in the area to monitor intraday demand and generation profiles. Using data from the sensors, Endeavour could provide the depot with insights on dynamic network capacity utilization, supporting flexible managed bus charging that maximizes grid use without requiring costly capacity upgrades. This approach cut the connection costs from A$6.5 million to A$2.5 million, speeded up connection time, and reduced disruption from laying underground cables in a busy commercial district.

Apply the right level of work to existing assets. A range of technologies and data sources—including drones, LiDAR, and satellite imagery—can help asset managers to determine the condition of assets and surrounding vegetation without sending multiple crews into the field. In addition, AI and generative AI can help automate digital data processing, defect and risk recognition and assessment, and even interpret hand-written notes from maintenance visits. By using this digitized data in predictive analytics, grid operators can evaluate the risk of assets failing and the impact this would have on the network, optimize maintenance and replacement decisions, and reduce spending and risk at every stage of the asset life.

Digitally transforming its asset management operations enabled a leading European utility to capture a 15% reduction in total asset-related capital and operational expenditure over a four-year period. To build its Asset Management 4.0 system, the utility worked in a series of agile sprints to iteratively build the digital asset management capability. This included developing new AI models for identifying the likelihood and impact of asset failures, building a predictive maintenance program with this information, and creating a new asset management operating model to implement the necessary changes in processes and organizational structures.

By combining LiDAR and satellite data with AI and machine learning capabilities, leading US, Australian, and European utilities are optimizing their vegetation management programs as well. This involves remotely identifying trees and plants, predicting their growth, anticipating problems before they arise, and jointly optimizing work plans with their contractors to take targeted actions at the best time. Through this proactive and data-driven approach, companies are able to reduce their vegetation-related expenditure by 20%–30% while managing risk better.

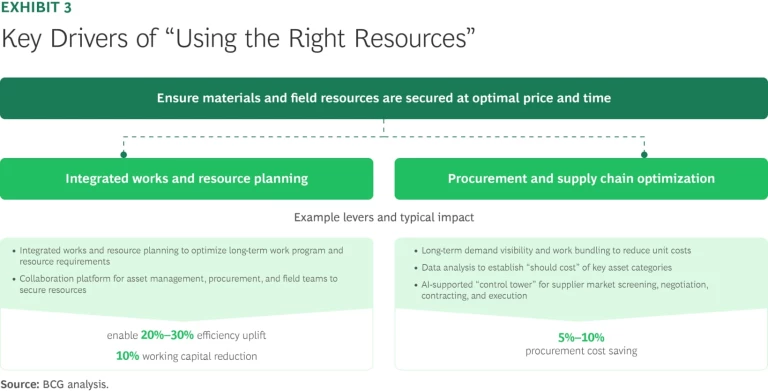

Second Imperative: Use the Right Resources

In the current environment of supply chain and workforce constraints, it is essential for energy networks to ensure that they have the right resources—not only at the right price but also at the right time. This enables them to reduce spend and secure the timely delivery of work. It also frees up working capital and thus helps with financing large capital programs. (See Exhibit 3.)

Use integrated work and resource planning. The first step grid companies must take is to develop better long-term visibility over their work programs (including both large projects and smaller, more routine activities). In this way, they can optimize the delivery timing, secure the necessary internal and external resources, and provide greater certainty to their delivery partners and suppliers. By enhancing visibility and avoiding excessive peaks and troughs in their work programs, companies are also in a stronger position to negotiate favorable terms with their suppliers.

Together with a US utility, BCG developed an AI-driven tool to help energy networks estimate resource requirements for their long-term work programs. This comprised a forecasting element that used algorithms to anticipate, at a granular level, what materials and labor resources companies require based on their future program of work. It also had a visualization element that provided company managers with an overview of the status of equipment and labor needed for specific projects and where these could be sourced. This approach helped transmission and distribution grids cut working capital by up to 10% and reduce project delays.

To manage its growing program of work, a European distribution grid operator used digital tools and algorithms to redesign how it plans work across multiple time horizons, including five-year strategic plans, annual investment workbooks, quarterly rolling resource plans, and scheduling up to the day of field operations. The approach has enabled the company to lower unit costs by 20%–30% by optimizing its work pipeline through better matching of technician supply and demand, reduced incidents of work being canceled close to execution, improved management of grid access and connection timelines, and better utilization of internal resources and supplier crews.

Build data-enabled procurement and supply chain management. Network companies also need to transform procurement and supply chain management into a more strategic function through greater use of data and analytics. Growing demand and constraints in production capacity mean that prices in some equipment categories have risen by two to three times over the last few years. And for grid players in the US, the introduction of new US tariffs is set to add an extra cost burden. Coupled with growing supplier lead times, such constraints result in cost increases and delays.

Faced with the need to deliver an ambitious 35% increase in its work program amid supply shortages, price volatility, and regulatory pressures, one regulated utility partnered with BCG to build a procurement function that was equipped to thrive in a challenging supply market. The utility was able to unlock 8%–10% of savings across key subcategories by bundling demand from multiple business units, diversifying the supply base, making forward-buying commitments, and forging strategic supplier relationships that involved its own C-suite.

Third Imperative: Do the Work Right

Having identified the right work and secured the right resources (at the right price and the right time), energy networks must ensure they spend only the right amount of effort on these tasks. In our experience, companies that improve the productivity of their employees and contractors can carry out their work programs using 20%–30% fewer resources.

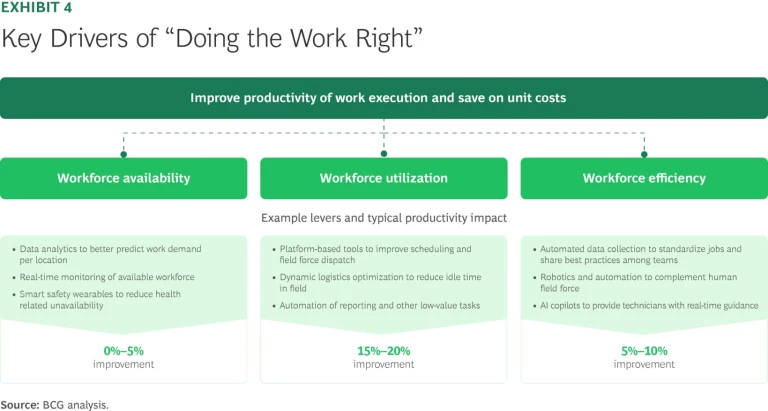

There are three key levers companies can pull to improve workforce productivity. (See Exhibit 4.)

Enhance workforce availability. AI and advanced data analytics can enhance workforce availability by helping companies to take a long-term view of the work that needs to be carried out and the amount of time involved. This enables them to move staff between regions or service centers so that they have sufficient labor resources to hand. In addition, real-time data can provide a more accurate picture of available workforce capacity when making day-to-day allocation decisions.

Data and analytics can also help optimize teams’ short- and long-term leave and shift arrangements within operational limitations (such as stand-down times after being on duty or unplanned leave), as well as their work schedules, to ensure field team capacity is available with the right capability mix to meet dispatch needs. Furthermore, by providing workers with smart safety wearables, companies can prevent safety and health-related incidents by monitoring individuals’ posture, concentration, and heart rate, and their use of protective equipment.

At BCG, we have partnered with one of our network clients to develop FYLD, an AI-powered frontline intelligence platform that supports infrastructure players with their field operations. The tool uses computer vision, including video footage of the site provided by workers, and predictive risk models, to assess situational risk in real time and alert field crews to hazards. It predicts the permits they will need, so they don’t hit downtime when the need for the permit eventuates. It also enhances operational excellence through an AI-driven command center that enables workers to raise issues and tackle bottlenecks, optimizes travel to the site, and carries out performance benchmarking. Since 2020, FYLD has enabled utilities to achieve a step change in safety outcomes, with a 48% reduction in incidents and injuries, and rapid productivity uplifts in the range of 8%–12%, with real-time, data-led quality assurance.

Improve workforce utilization. Workforce utilization can be improved in various ways by reducing the time spent on low-value activities. This involves, for example:

- Better work scheduling to minimize idle time and time spent travelling to jobs

- Better logistics so that time is not wasted on vehicle refueling or trips to the depot to pick up parts and tools

- Automation of low-value tasks such as job reporting

- Provision of a steady stream of well-prepared jobs that can fill up a crew’s time in the field. This starts with “doing the right work” and improving integrated work and resource planning capabilities.

Platform-based workforce management systems that leverage advanced optimization engines to solve complex scheduling and logistics challenges, and automate routine tasks, are becoming a must-have in the area of field mobility. These systems enable companies to make the most productive use of their available resources, allocate tasks effectively, and navigate constraints, such as work permits or traffic jams.

In our experience, companies that successfully empower their field crews with advanced data and optimization engines can get more work done with the field technicians they already have and lower the ratio of schedulers to field technicians. For example, a European energy network was able to increase its work teams’ utilization by 50% and reduce coordination activities by 50%–70%.

A US-based utility decreased idle time and overtime by nearly 20% using an AI-driven solution to optimize dispatching, scheduling, and routing. The tool integrates live feeds of work orders, technician availability and qualifications, and location to generate optimized schedules and rebalance as disruptions occur during the day.

Improve workforce efficiency. Data, automation, and AI play an increasingly important role in enabling companies to improve the efficiency of field crews while they are working on site.

Collecting data from field operations allows energy networks to create and continuously improve a library of standardized tasks with uniform parameters, such as time needed to perform a job, the equipment requirements, and crew size and skills. The resulting “standard jobs” help companies to automate scheduling and resource allocation and can serve as the basis for performance management. Similarly, mobile, GenAI-enabled copilots are giving field technicians real-time guidance on solving technical faults, acting as sources of information for different equipment and defect types, and executing post-job reporting.

Robotics and automation tools, meanwhile, can enable energy networks to send smaller crews into the field. For example, drones can be used to assist workers in carrying out remote inspections of powerlines and towers and perform activities such as restringing conductors. Leading networks are creating digital models of their key assets to help their work teams remotely and safely monitor and maintain them, reducing travel costs and time spent waiting for workers with the right skills to become available.

SA Power Networks in Australia leveraged a digital twin of its distribution assets created by Neara to improve the effectiveness of its response to a severe flood. Modeling the flood’s impact on its power lines resulted in SAPN being able to avoid unnecessary field visits to inspect the assets. As a result, SAPN was able to re-energize impacted power lines within days when the flood waters receded, rather than potentially weeks using traditional approaches.

Making It Happen

To put the three imperatives into practice—and so achieve significant improvements in productivity—the leading grid companies take a systemic approach:

Learn from others. As the examples above show, there are many instances of global grid companies successfully executing productivity improvement initiatives. Finding one that is relevant to your company and adapting it as necessary is the surest way to achieve quick impact.

Start small, move fast. Many companies have achieved success with developing digital solutions by starting with limited proof-of-concept and minimum viable products and then extending them to their entire operations in stages. The best off-the-shelf products also offer these options and can be tested before engaging in a large transformation.

Focus on changing the way people work. Such efforts require substantial changes to well-established routines. However, this will not happen without an active approach to transformation, dedicated teams, and support from senior management. It is important to invest in data and digital technologies, but most critical to remember that 70% of the value comes from changing the way people work.

Energy networks are under greater strain than ever. To meet the demands of customers, investors, and regulators, grids need to find smart ways to grow. A three-pronged approach—doing the right work, using the right resources, and doing the work right— can help enable growth with productivity, with data analytics and AI as force multipliers.

The authors would like to thank BCG colleagues Shashank Shekhar, Shubham Kumar, John Snipes, Zsofia Beck, Lasse Petersen, Marc Ahlers, and Richard Hobbs for their contributions to this article.