The energy transition continues to weather shifting winds. For example, returns on renewable energy projects have significantly deteriorated over the past three years, driven by an increase in capital expenditures, operating expenses, and interest rates. Today’s geopolitical uncertainties are putting additional constraints on global supply chains, making on-time and on-budget delivery of such projects ever more challenging.

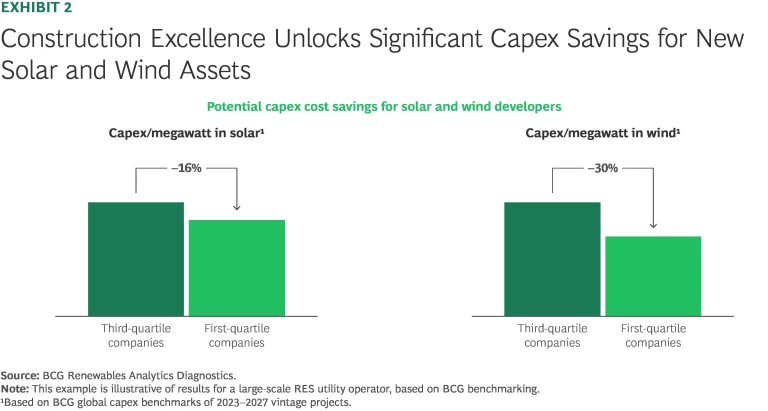

Yet amidst these pressures, some renewable energy project developers are containing costs much more effectively than their competitors. BCG benchmarking found that the top-quartile companies spend 16% less in dollars per megawatt on solar photovoltaics and 30% less on wind when building new assets (compared to companies in the third quartile). So what separates the top performers from the rest of the pack?

Stay ahead with BCG insights on energy

Wind Energy: A Case Study

To address this question, we conducted an in-depth examination of wind energy, which faces some of the most complex barriers in the renewable sector. Because the risks and costs of wind projects closely mirror those of other renewable technologies, this case study offers lessons that extend well beyond wind—serving as a practical blueprint for wind, solar, and battery storage companies aiming to scale efficiently.

Over the past two to three years, wind developers have experienced a 30% to 50% rise in capital expenditures, and some leading developers have begun to pause or cancel projects. Three main barriers have stalled progress.

Supply Chain Challenges

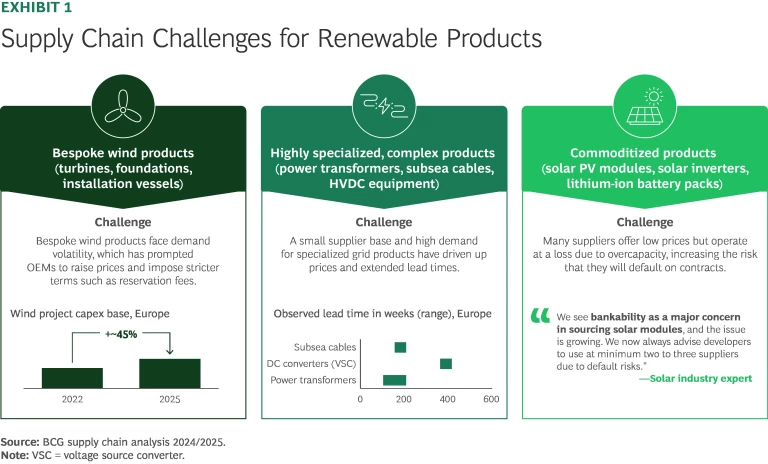

Wind, solar, and battery storage all face acute supply chain risks, including demand volatility, rising costs, and geopolitical dependence on critical inputs. (See Exhibit 1.) Here’s a closer look at some specific challenges in wind energy.

- Rising costs. Developers are finding it increasingly difficult to secure key wind components, such as turbines, foundations, and installation equipment, at cost levels that match the requirements of the business case. To manage unpredictable demand, suppliers are raising prices and requiring higher upfront reservation fees.

- Long waits. Wind developers face long lead times for complex components like power transformers, subsea cables, and high-voltage direct current (HVDC) equipment. These specialized products are in high demand, but only a few suppliers exist, creating bottlenecks that delay projects and drive up costs.

- Geopolitical risks. Some critical components like rare earth elements and large-diameter flanges are sourced from only a handful of regions around the world. This geographic concentration makes the wind supply chain vulnerable to political instability, trade restrictions, and other global disruptions.

Installation Disruptions

Installation is one of the most complex and resource-intensive phases of offshore and onshore wind development. Several factors can create challenges during this phase of the project.

- Shortages in specialized installation equipment. There is a limited supply of specialized installation vessels, large cranes, and port capacity for delivery and marshalling of large wind farm components. To make matters more complicated, the rapid evolution of turbine components can render existing heavy installation equipment obsolete within just a few years.

- Weather dependencies. Installation activities are heavily reliant on favorable weather windows, which can lead to significant scheduling uncertainties and delays. Harsh conditions, strong winds, or storms at renewable energy sites frequently disrupt installation schedules and construction work.

- Escalating installation costs. Because of supply chain challenges, developers face prolonged installation phases that inflate project costs. To manage these risks, developers often add buffer time to equipment rentals, but doing so increases costs.

Regulatory, Environmental, and Grid Connection Hurdles

Navigating the regulatory and environmental landscape poses significant challenges for wind energy developers.

- Permitting complexity. Permitting rules vary widely across countries and often cause multi-year delays in project approvals. In some cases, projects have even had their permits revoked after construction had already begun.

- Environmental standards. New environmental regulations mandating stricter protections for marine ecosystems, bird and wildlife habitats, and environmentally sensitive areas increase the complexity and cost of compliance for wind, solar, and BESS projects.

- Grid constraints and connection delays. In many countries, the power grid can’t keep up with the rapid growth of new wind, solar, and BESS projects. Grid connection requests for BESS are already oversubscribed in several European countries, limiting the ability to add more renewable energy projects. In Germany, so many large-scale battery projects seek to be connected to the country’s grid, it’s being called a “battery tsunami.”

In addition to these barriers, there is a significant workforce shortage in the renewable energy sector, particularly in specialized, high-demand roles. BCG has calculated the skills gap in the green economy will rise to 7 million by 2030, particularly in wind, solar, and biofuels technologies. The lack of experienced workers is creating bottlenecks and slowing project execution.

Achieving Construction Excellence in Renewables

BCG benchmarking shows that when companies get construction right in renewables, they can achieve up to 30% savings. (See Exhibit 2.)

Top-performing companies excel in three specific areas: standardization, logistics optimization, and workforce management. Their actions provide a blueprint for reducing costs and minimizing disruptions while laying the foundation for long-term scalability and resilience.

Standardizing Processes and Components

Standardization and modularization have the potential to revolutionize renewables construction. Standardizing processes from the permitting stage through construction and standardizing components can shorten project timelines, lower costs, and create a more resilient supply chain. For example, when modular substations are built in standardized units that can be deployed and connected on site, installation times can be reduced by up to 40%.

Establish industry-wide standards.

Common standards for design and manufacturing can reduce complexity and improve compatibility across projects. For example, wind turbine manufacturers often face different testing requirements. One customer may require an ultrasound test, while another demands an X-ray for the same turbine. Aligning on common quality and testing procedures would streamline production, lower costs, and make delivery timelines more predictable. Organizations like SolarPower Europe and the Solar Energy Industries Association publish best practice guidelines for the solar industry, including standardized installation procedures, safe handling and transport of solar modules, and grounding and lightning protection.

Use modular components.

Prefabricated and modular designs enable faster assembly and reduce the time spent on site. Modular components improve quality because construction happens in a controlled environment, rather than on a field, at a harbor dock, or at sea, which means fully assembled units can be functionally pretested before installation and rapidly deployed on site. Solar companies have proven the success of this model, and it should be rolled out to other renewables as well. BESS companies are increasingly adopting modularization. Pre-integrated battery containers (such as Tesla’s Megapack), plug-and-play inverter blocks, and modular energy management systems have become industry standards, enabling faster permitting, easier transport, and quicker commissioning.

Optimizing Logistics and Digital Tools

Logistics optimization and digital tools are critical to improving efficiency. Enhanced logistics planning can cut downtime by 20% to 30%, unlocking substantial cost savings and bringing greater predictability to project execution.

Improve logistics operations.

By coordinating transportation, storage, and on-site delivery, companies can minimize delays and ensure the efficient use of resources. AI-enabled logistics tools can quickly identify delays that would impact the overall project timeline. For offshore wind projects, digital platforms like Metocean Analytics and StormGeo provide tailored wave and wind forecasts, enabling precision in installation planning.

Leverage advanced planning tools.

Digital twin technology and predictive analytics allow developers to simulate each phase of construction and identify potential bottlenecks. Digital and AI-powered planning systems can continuously adjust the schedule based on weather and wave forecasts, while using recent performance data to improve future predictions. Supply chain data can also be linked to planning systems to ensure that material will arrive on time. Renewable energy project developers are increasingly using AI-based tools, such as ALICE, nPlan, or Primavera Cloud, to continuously optimize construction schedules around evolving constraints. End-to-end digital twins, now offered by several of the leading wind turbine OEMs, allow scenario testing that reduces installation risk and improves design efficiency.

Addressing Workforce Shortages and Promoting Industry Collaboration

A shortage of skilled workers and the need for stronger cross-industry collaboration are key challenges in delivering renewables efficiently. Addressing these issues can help ensure a sustainable pipeline of talent, enhance safety standards, and foster innovation by leveraging shared resources and expertise across the industry.

Build a green workforce.

Targeted training and upskilling programs, particularly for workers transitioning from adjacent industries like oil and gas, can help address labor gaps. Governments can fund and scale training programs to upskill and retrain workers in green skills. BCG estimates that about 40% of the required workers will need only limited training.

Expand collaborative relationships.

Increased collaboration across the supply chain and among developers (by sharing installation vessel capacity, for example) can improve overall efficiency and resource utilization. Smaller developers who try to engage in deeper collaboration with suppliers are often faced with a low level of interest for engagement. Building larger industry partnerships between developers and then approaching suppliers can yield much more attention. In the EU, offshore wind developers have collaborated on advanced simulation models, reducing steel use in towers and monopiles by up to 20%, contributing to 5% to 10% levelized cost of energy savings.

The challenges of growing demand, supply chain constraints, and fragmented collaboration affect all large-scale renewable technologies. Achieving scale and cost efficiency in renewables—by delivering projects on time and on budget through construction excellence—has become a strategic priority. Unlocking this potential will require greater standardization, digital integration, and workforce renewal across developers, suppliers, and public stakeholders.